A step-by-step cutting machine for aerated concrete

An air-entrained concrete, step-by-step technology, applied in the field of step-by-step cutting machines, can solve the problems of inconvenient operation and maintenance, inaccurate cutting positioning, asynchronous lifting of the green body, etc., and achieves difficult drift and high cutting accuracy. , The effect of easy operation of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

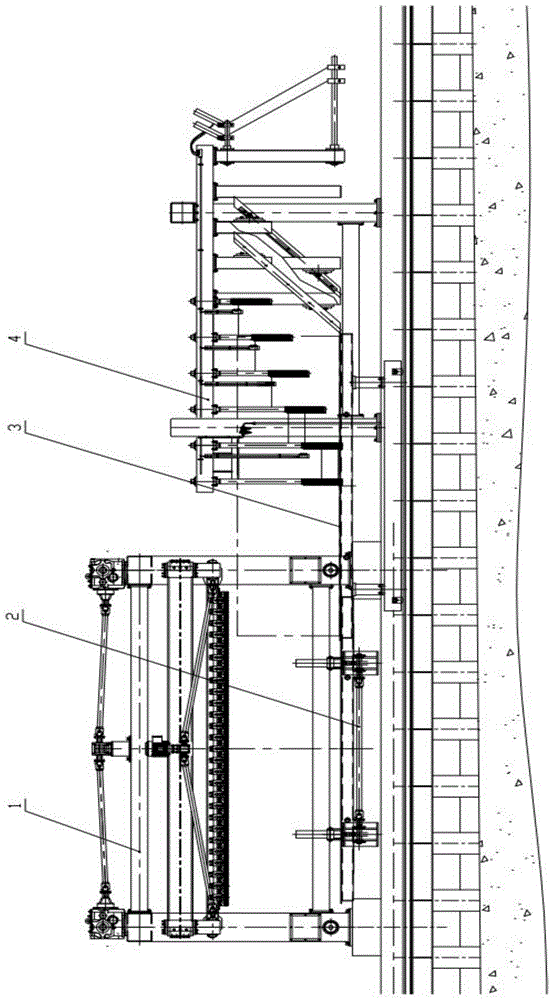

[0024] combine figure 1 , a step-by-step cutting machine for aerated concrete, including a traction device 3 for transporting a green body, a slitting device 4, a vehicle changing device 2 for sending the green body to a cross-cutting station, and a cross-cutting device 1 for completing the cross-cutting, The slitting device includes a side elevation milling device for removing the bread head, a horizontal cutting device for longitudinally dividing the green body, and a remover for removing the waste on the top surface.

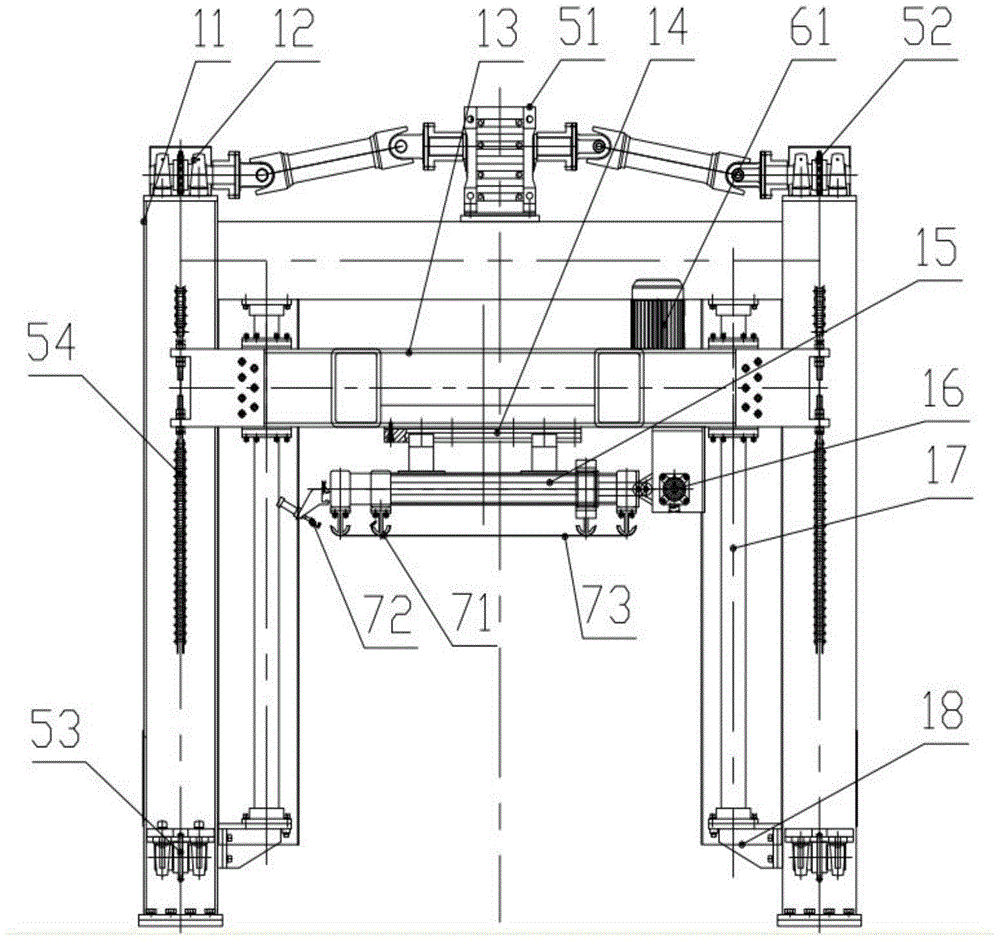

[0025] combine figure 2 The cross-cutting device 1 includes a frame 11, and the lifting mechanism 12 drives the cross-cutting frame 13 to lift along the guide rod 17. The bottom of the cross-cutting frame 13 is connected with the pendulum frame 15 through the I-shaped guide rail 14, and the pendulum frame 15 is sleeved on the green body. A swing mechanism 16 is arranged on both sides, and the bottom of the guide rod 17 is connected with the frame 11 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com