Preparation method of polyurethane-polymethyl methacrylate block copolymer

The technology of polymethyl methacrylate and hydroxyl-terminated polymethyl methacrylate is applied in the field of preparation of polyurethane-polymethyl methacrylate block copolymer, and can solve the problems of large amount of catalyst and difficult removal, and the like, To achieve the effect of reducing air sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

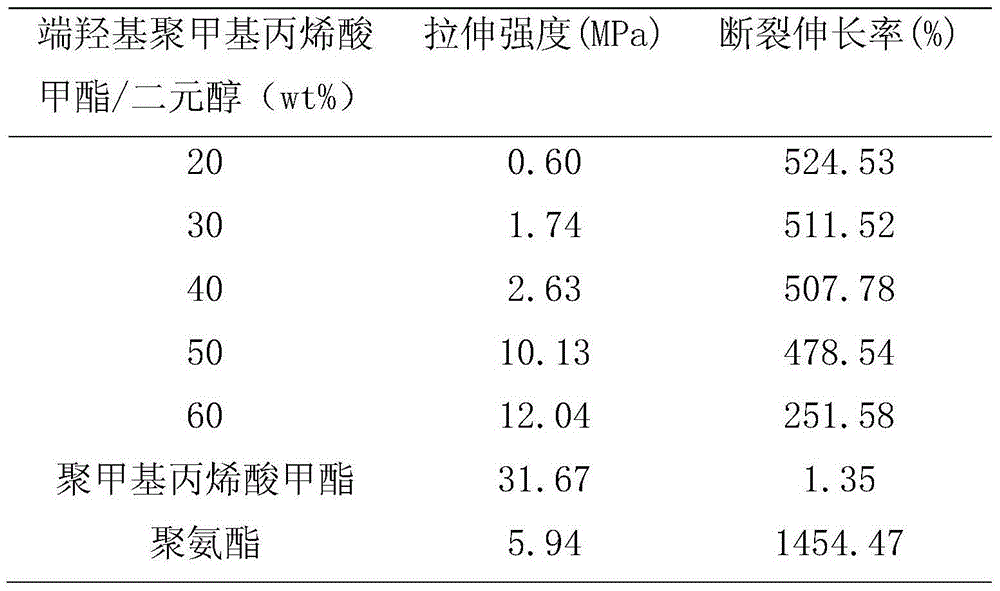

Embodiment 1

[0020] (1) Preparation of hydroxyl-terminated polymethyl methacrylate with molecular weight of 10000

[0021] In a 500mL four-neck flask equipped with a thermometer, add 100g of methyl methacrylate, 3.0253g of hydroxybutyl α-bromoisobutyrate (purity is 79%), CuBr 2 0.1117g, 0.8318g of pentamethyldiethylenetriamine, 3.0883g of stannous octoate, 50g of toluene, mechanically stir and mix evenly, bubbling for 5min to remove oxygen in the system, and continue bubbling reaction in an oil bath at 70°C After 3.5 hours, the conversion rate was 81%. The molecular weight M was measured by gel permeation chromatography (GPC) n =11440, molecular weight distribution PDI=1.23. In this reaction, the amount of the catalyst used is 500 ppm of the molar amount of the monomer, and a polymer with controllable molecular weight and narrow molecular weight distribution is obtained.

[0022] (2) Preparation of polyurethane-polymethyl methacrylate block copolymer

[0023] Take the polyurethane-poly...

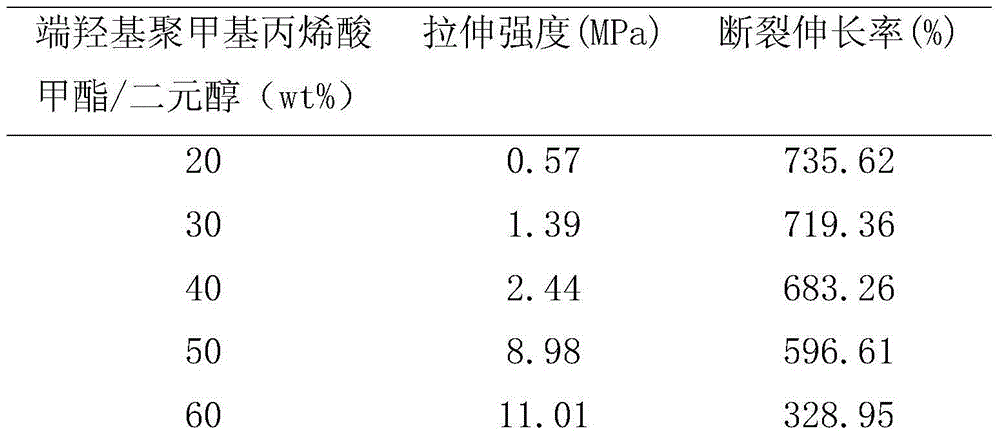

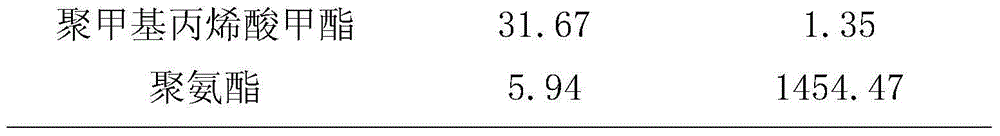

Embodiment 2

[0027] (1) Preparation of hydroxyl-terminated polymethyl methacrylate with molecular weight of 8000

[0028] In a 500mL four-necked flask equipped with a thermometer, add 100g of methyl methacrylate, 3.3194g of hydroxybutyl α-bromoisobutyrate (purity is 90%), CuBr 2 0.1115g, 0.8654g of pentamethyldiethylenetriamine, 3.0346g of stannous octoate, 50g of anisole, mechanically stir and mix evenly, bubbling for 5min to remove the oxygen in the system, continue bubbling in an oil bath at 70°C After 3.5 hours of bubble reaction, the conversion rate was 86%. The molecular weight M was measured by gel permeation chromatography (GPC) n =7800, molecular weight distribution PDI=1.31. In this reaction, the amount of the catalyst used is 500 ppm of the molar amount of the monomer, and a polymer with controllable molecular weight and narrow molecular weight distribution is obtained.

[0029] (2) Preparation of polyurethane-polymethyl methacrylate block copolymer

[0030] Take the polyure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com