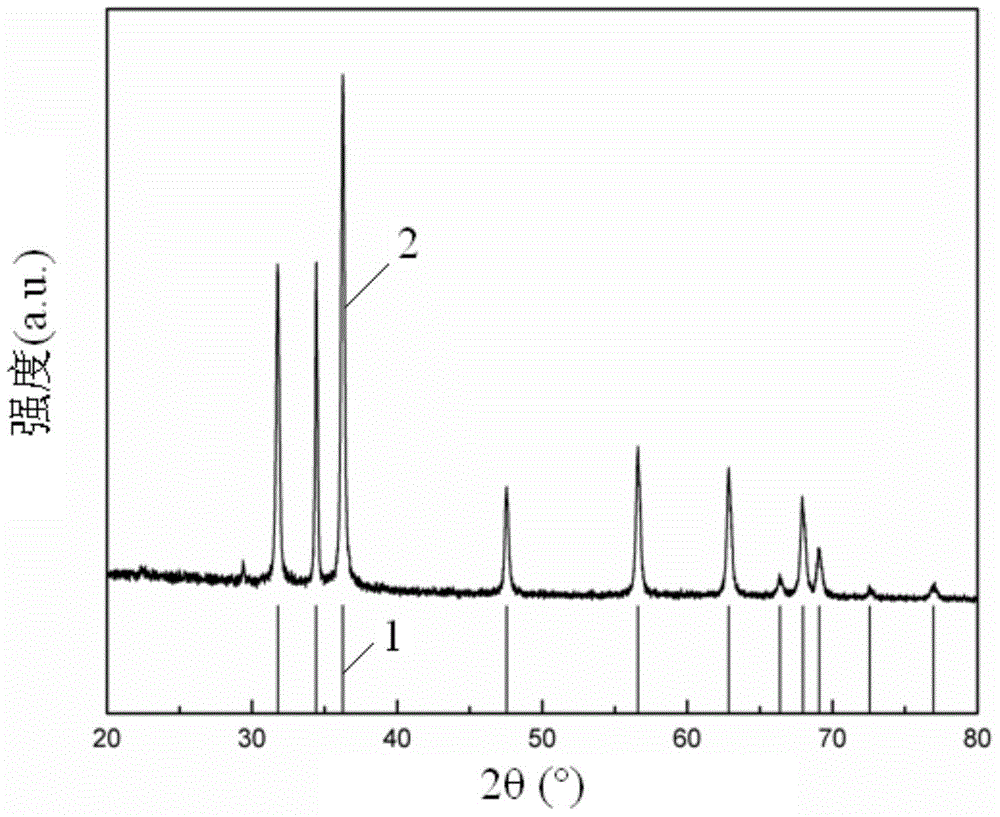

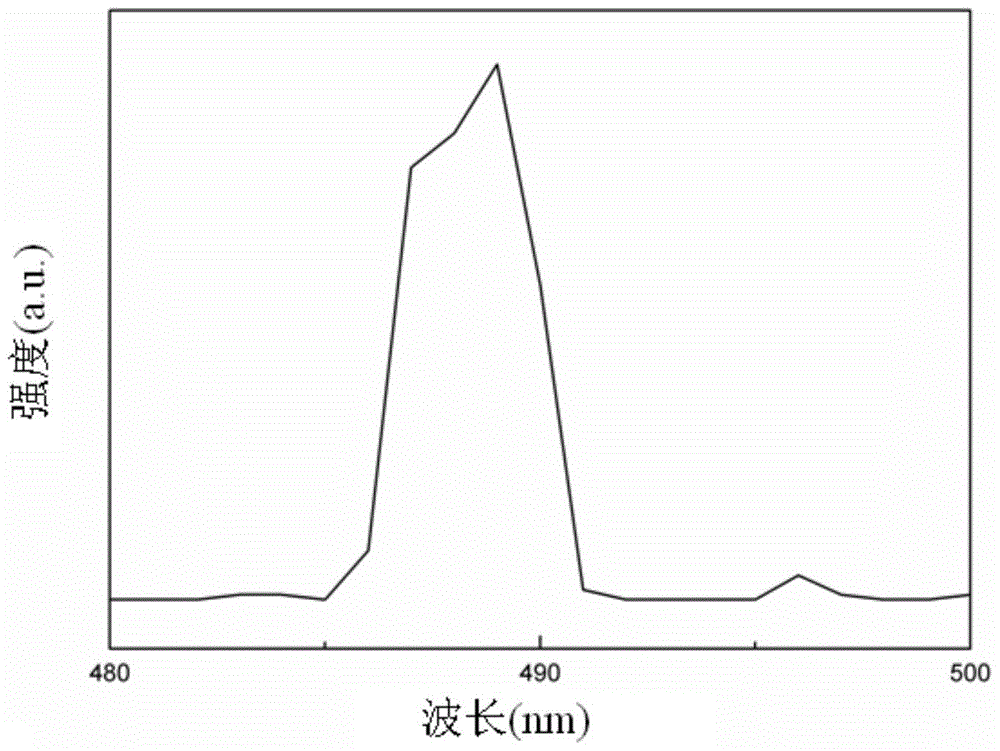

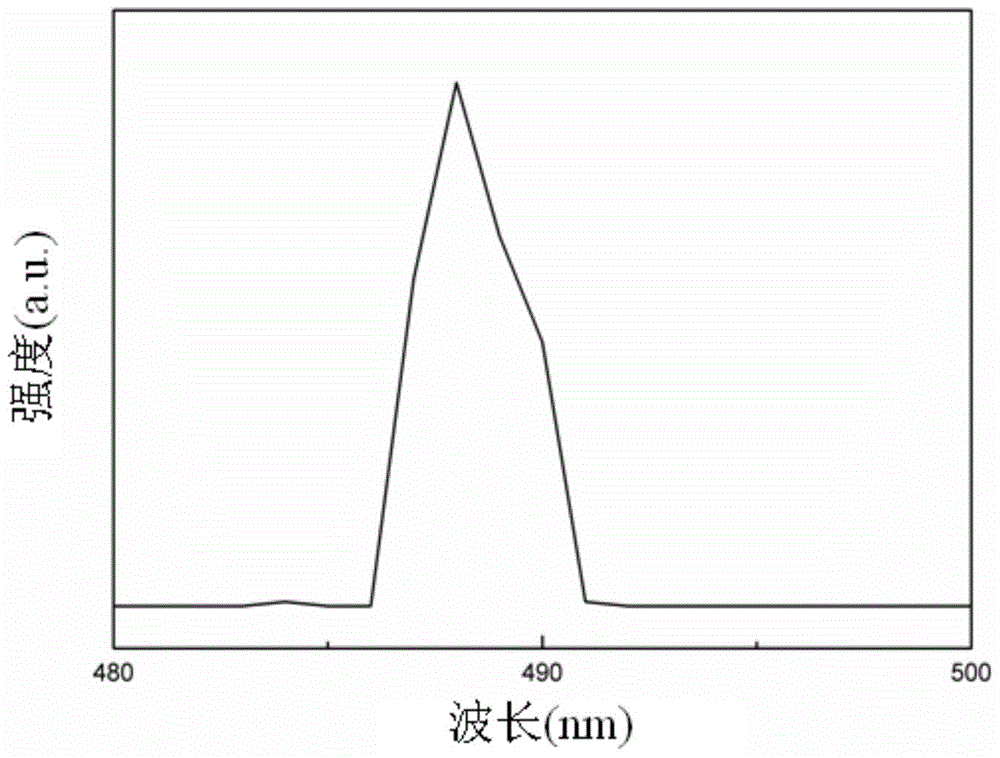

Preparation method of a narrow-band ytterbium-thulium double-doped gzo nano-fluorescent material

A nano-fluorescent, narrow-band technology, applied in the field of preparation of GZO nano-fluorescent materials, can solve the problems of large particle size, unfavorable application, wide band distribution, etc., achieve wide application value and reduce the effect of wavelength range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] Embodiment 1: This embodiment is a preparation method of a narrow-band ytterbium-thulium double-doped GZO nano-fluorescent material, which is completed according to the following steps:

[0029] 1. Add the NaOH solution with a mass fraction of 4% to 8% dropwise at a rate of 30 drops / min to 60 drops / min to the Zn(NO 3 ) 3 solution, to obtain a mixed solution A; then the mass fraction is 0.2% to 1.5% Ga(NO 3 ) 3 The solution was added dropwise to the mixed solution A at a rate of 30 drops / min to 60 drops / min, and then magnetically stirred at a stirring speed of 600r / min to 800r / min for 20min to 30min to obtain a mixed solution B;

[0030] NaOH and Zn(NO 3 ) 3 The molar ratio of the substance is 4:1;

[0031] In the mixed solution B described in step 1, Zn(NO 3 ) 3 and Ga(NO 3 ) 3 The molar ratio of the substance is 100:1;

[0032] 2. Add 1mol%~9mol% ytterbium oxide nitric acid solution into the mixed solution B, then add 1mol%~2mol% thulium oxide nitric acid sol...

specific Embodiment approach 2

[0046] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, the NaOH solution that mass fraction is 6%~8% is added dropwise to mass with the rate of addition of 40 drops / min~60 drops / min The fraction is 7%~9% Zn(NO 3 ) 3 solution, a mixed solution A was obtained. Others are the same as the first embodiment.

specific Embodiment approach 3

[0047] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step one, Ga(NO 3 ) 3 The solution is added dropwise to the mixed solution A at a rate of 40 drops / min to 60 drops / min, and then magnetically stirred at a stirring speed of 700r / min to 800r / min for 25min to 30min to obtain a mixed solution B. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com