Ultra high molecular weight polyethylene core spun yarn and preparation method thereof

A technology of ultra-high molecular weight and polyethylene, which is applied in the direction of yarn, textile and paper making, and can solve problems such as small friction coefficient, low yarn strength, and poor yarn quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

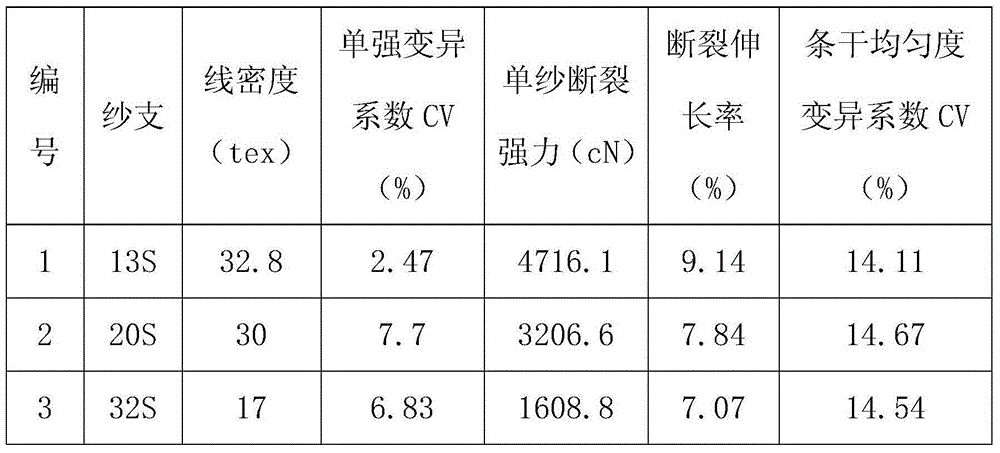

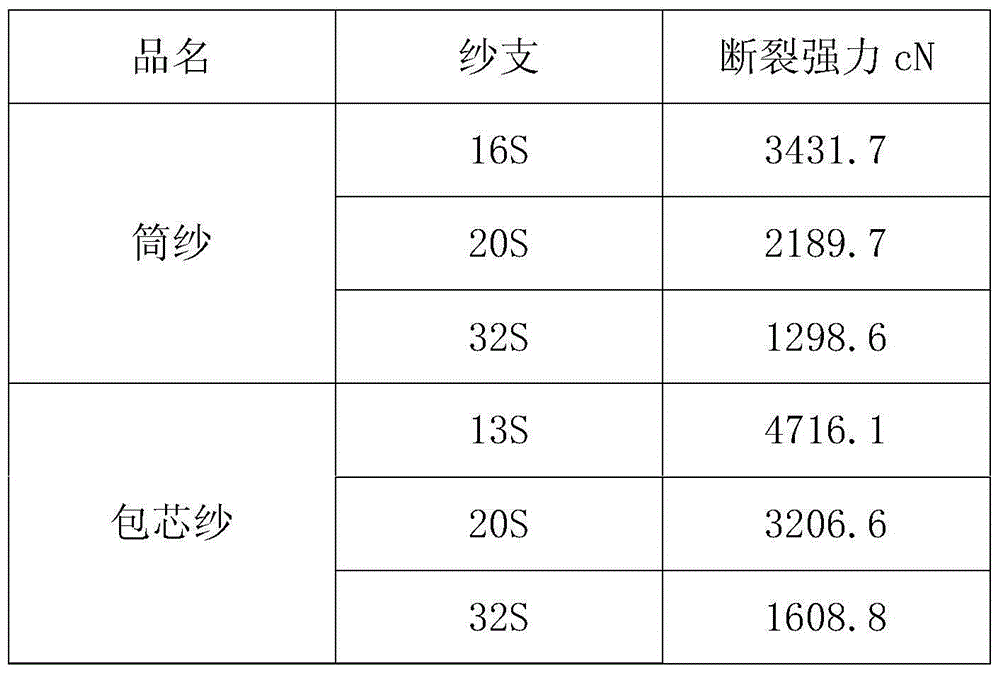

specific Embodiment 1

[0016] An ultra-high molecular weight polyethylene core-spun yarn, comprising ultra-high molecular weight polyethylene filaments and ultra-high molecular weight polyethylene short fibers, the ultra-high molecular weight polyethylene filaments are the core yarn of the core-spun yarn, and the ultra-high molecular weight polyethylene Polyethylene staple fiber is uniformly covered with ultra-high molecular weight polyethylene filament core wire; the core-spun yarn forming the core wire contains: UHMWPE filament blend ratio 30%, UHMWPE staple fiber blend ratio 70% , the specification of the ultra-high molecular weight polyethylene filament is 50D, and the count of the finished core-spun yarn is 13S. The length of the ultra-high molecular weight polyethylene short fiber is: 50mm.

[0017] The preparation method of the ultra-high molecular weight polyethylene core-spun yarn comprises the following steps: pretreatment → blowing and carding → first drawing frame → secondary drawing fra...

specific Embodiment 2

[0023] An ultra-high molecular weight polyethylene core-spun yarn, comprising ultra-high molecular weight polyethylene filaments and ultra-high molecular weight polyethylene short fibers, the ultra-high molecular weight polyethylene filaments are the core yarn of the core-spun yarn, and the ultra-high molecular weight polyethylene Polyethylene staple fiber is uniformly covered with ultra-high molecular weight polyethylene filament core wire; the core-spun yarn forming the core wire contains: blending ratio of ultra-high molecular weight polyethylene filament filament 40%, blending ratio of ultra-high molecular weight polyethylene staple fiber 60% , the specification of the ultra-high molecular weight polyethylene filament is 200D, and the count of the finished core-spun yarn is 32S. The length of the ultra-high molecular weight polyethylene short fiber is: 57mm.

[0024] The preparation method of the ultra-high molecular weight polyethylene core-spun yarn comprises the followi...

specific Embodiment 3

[0030]An ultra-high molecular weight polyethylene core-spun yarn, comprising ultra-high molecular weight polyethylene filaments and ultra-high molecular weight polyethylene short fibers, the ultra-high molecular weight polyethylene filaments are the core yarn of the core-spun yarn, and the ultra-high molecular weight polyethylene Polyethylene staple fiber is uniformly covered with ultra-high molecular weight polyethylene filament core wire; the core-spun yarn forming the core wire contains: UHMWPE filament blend ratio 35%, ultra-high molecular weight polyethylene staple fiber blend ratio 65% , the specification of the ultra-high molecular weight polyethylene filament is 140D, and the count of the finished core-spun yarn is 27S. The length of the ultra-high molecular weight polyethylene short fiber is: 54mm.

[0031] The preparation method of the ultra-high molecular weight polyethylene core-spun yarn comprises the following steps: pretreatment → blowing and carding → first dra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com