A kind of water-based flexible handle coating and preparation method thereof

A flexible and hand-feeling technology, which is applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of not having a delicate hand feel, being difficult to meet the soft hand feeling, and high difficulty in synthesis, so as to reduce the system The risk of gelation, good resilience, and the effect of reducing the reaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

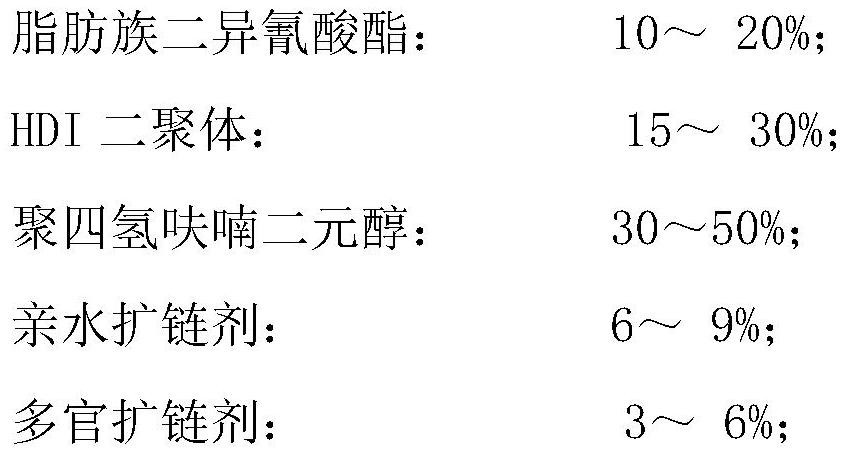

[0040] The water-based flexible handle coating of the present embodiment is prepared by using the raw materials of the following components and contents:

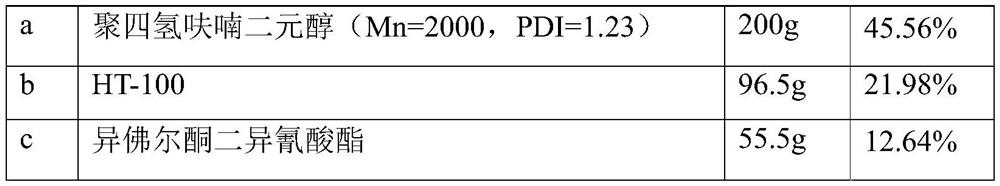

[0041]

[0042]

[0043] The above-mentioned water-based flexible handle coating is prepared according to the following process steps:

[0044] Component a was stirred and dehydrated at 85° C. under vacuum, and the stirring speed was 200 rpm. After the water content in component a is less than 200ppm, stop vacuuming and return to normal pressure. Keep stirring and add components b and c, keep the reaction at 85°C for 2h. Keep stirring and add component d, keep the reaction at 85°C for 2h, if the viscosity is too high, add component h. Lower the temperature to 75°C, keep stirring and add component e, keep at 75°C and continue the reaction for 2h, when the viscosity is too high, add component h. Cool to 50°C, add component f, and continue stirring for 30 minutes before discharging. Disperse the synthesized resin at ...

Embodiment 2

[0046] The water-based flexible handle coating of the present embodiment is prepared by using the raw materials of the following components and contents:

[0047] a Polytetrahydrofuran diol (Mn=3000, PDI=1.30) 150g 41.23% b HT-100 104.2g 28.65% c 4,4'-Dicyclohexylmethane diisocyanate 39.3g 10.80% d Dimethylolpropionic acid 24.1g 6.63% e Trimethylolpropane 20.1g 5.53% f N,N'-Dimethylethanolamine 14.7g 4.04% g Tetraethylenepentamine 11.3g 3.12% h acetone 170g - i Deionized water 760g -

[0048] The above-mentioned water-based flexible handle coating is prepared according to the following process steps:

[0049] Component a was stirred and dehydrated at 85° C. under vacuum, and the stirring speed was 200 rpm. After the water content in component a is less than 200ppm, stop vacuuming and return to normal pressure. Keep stirring and add components b and c, keep the reaction at 85°C for 2h. Keep stirr...

Embodiment 3

[0051] The water-based flexible handle coating of the present embodiment is prepared by using the raw materials of the following components and contents:

[0052] a Polytetrahydrofuran diol (Mn=2000, PDI=1.23) 130g 35.19% b HT-100 104.2g 28.21% c 4,4'-Dicyclohexylmethane diisocyanate 52.4g 14.19% d dimethylolbutyric acid 28.8g 7.80% e Trimethylolpropane 22.1g 6.00% f N,N'-Dimethylethanolamine 16.3g 4.42% g pentaethylene hexamine 14.3g 4.02% h acetone 180g - i Deionized water 770g -

[0053] The above-mentioned water-based flexible handle coating is prepared according to the following process steps:

[0054]Component a was stirred and dehydrated at 85° C. under vacuum, and the stirring speed was 200 rpm. After the water content in component a is less than 200ppm, stop vacuuming and return to normal pressure. Keep stirring and add components b and c, keep the reaction at 85°C for 2h. Keep stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com