Temperature measurement method of micro-reactor based on neural network

A neural network and temperature measurement technology, which is applied to thermometers, measuring devices, and heat measurement, can solve problems such as difficult to effectively reflect the real temperature value, low signal-to-noise ratio, and susceptibility to interference, and achieve fast convergence and recognition speed and learning The effect of short time and reduced environmental interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

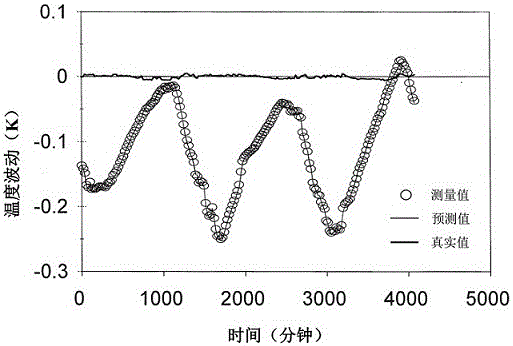

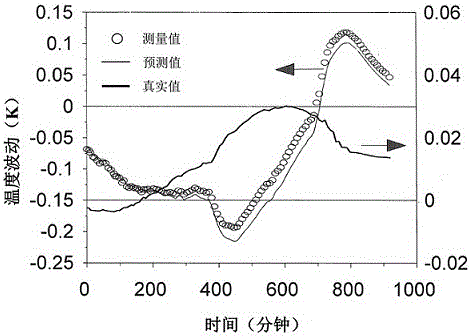

[0038] As mentioned above, the present invention provides a method for measuring the temperature of a micro-reactor based on a neural network, which can reduce noise, correct the temperature signal, improve the signal-to-noise ratio and measurement accuracy, and is used in fields such as analysis, micro-chemical industry, and micro-energy systems. Measurement of temperature field and temperature distribution of micro-reactor. The content of the present invention is illustrated by the following examples combined with the temperature test of the micro-reactor, but the scope of the present invention is not limited.

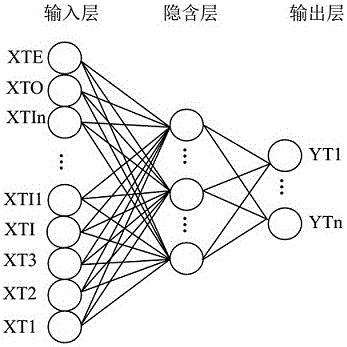

[0039] The present invention is based on the tiny reactor temperature measuring method of neural network, comprises the following steps:

[0040] (1) Obtain the characteristic temperature measurement signal and target temperature measurement signal parameters at different locations.

[0041] The structural arrangement of the micro-reactor temperature measurement emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com