Three-directional shearing model box device

A technology for shearing model boxes and rubber molds, which can be used in measurement devices, vibration testing, and testing of machine/structural components. Easy installation and application, simple construction, low mass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

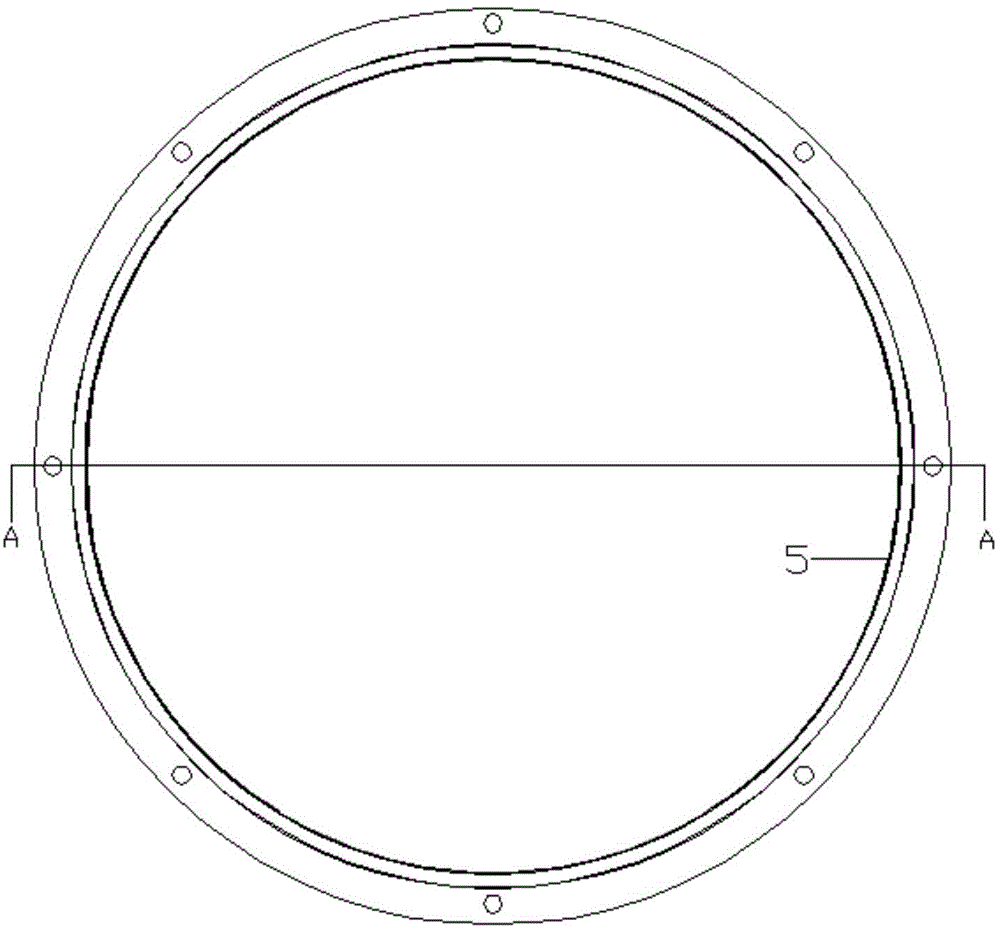

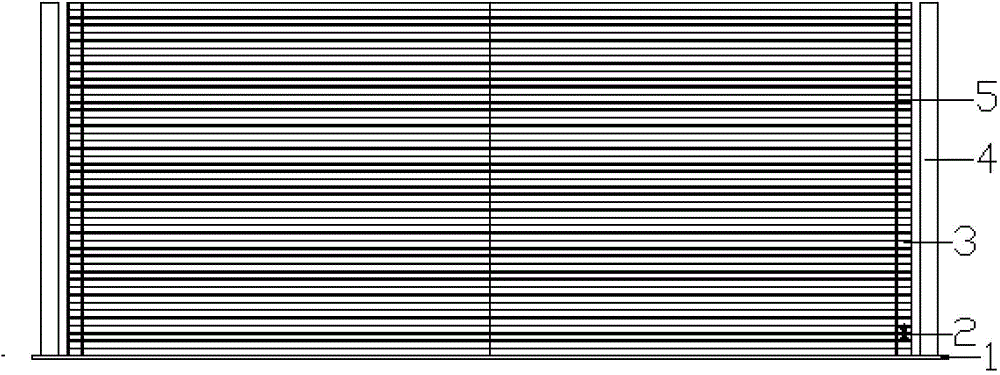

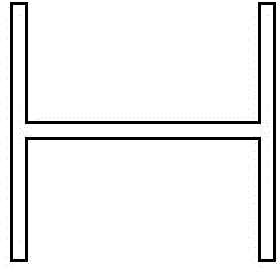

[0021] Such as Figure 1-3 As shown, a three-way shear model box device according to an embodiment of the present invention includes: a steel plate, a plurality of frame layers, which are installed on the upper part of the steel plate 1; the frame layer includes: a multilayer frame 3, rubber Die 5, which is riveted on the inside of the frame 3; Support 2, which is installed between the frame 3 layers of the column 4, which is installed on the periphery of the steel plate 1; The frames 3 are arranged vertically and equidistantly in parallel The frame 3 is a circular closed aluminum alloy H-shaped steel, the upper part of the support 2 has the same structure as the lower part, and the support 2 and the uprights 4 are arranged at equal intervals. In the shear model box, the steel plate 1 should have sufficient bearing capacity to ensure safety during the hoisting process; the frame 3 is aluminum alloy H-shaped steel, and the aluminum alloy H-shaped steel is welded by argon arc to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com