Preparation method of sintered Nd-Fe-B permanent magnet material

A permanent magnet material, neodymium iron boron technology, applied in the direction of magnetic materials, inorganic material magnetism, magnetic objects, etc., can solve the problem that the corrosion resistance of sintered neodymium iron boron magnets needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

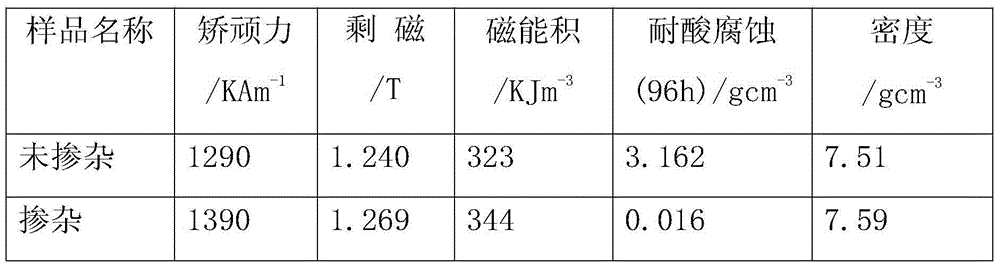

[0020] The NdFeB alloy is prepared into flakes by using the quick-setting technology, and then the powder is made into a powder with an average particle size of 2.8 microns by using a hydrogen crushing-jet milling process, and then 0.2% by weight of M nano powder is mixed with it, M nano The average particle size of the powder is 53 nanometers, 61 nanometers and 87 nanometers, and the surface-treated Mg:Al:Cu=1:1:2 (weight ratio) mixed nano-powder is doped into the above-mentioned initial powder. The machine mixes the two powders evenly. The uniformly mixed powder was oriented in a magnetic field of 2.5T and pressed into shape. The obtained compact was put into a 30MPa cold pressing pool, and compressed and shrunk after 10 minutes. Then put the shrunken compact into a high vacuum sintering furnace, then raise the temperature, stay at 200oC and 850oC for 1 hour and 2 hours respectively, sinter at 1050oC for 4 hours, and finally carry out secondary heat treatment. The temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com