Dipolar permanent magnet synchronous submersible electric motor

A permanent magnet synchronous motor technology, applied in the direction of synchronous machine parts, electric components, magnetic circuit rotating parts, etc., can solve problems such as lack of asynchronous starting, underutilization of permanent magnets, difficulties in electromagnetic scheme design, etc. , to achieve the effect of strong magnetic field energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

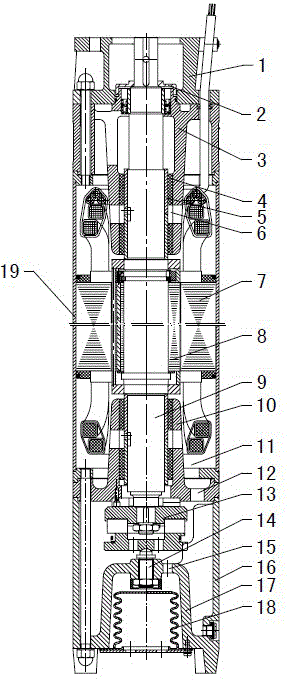

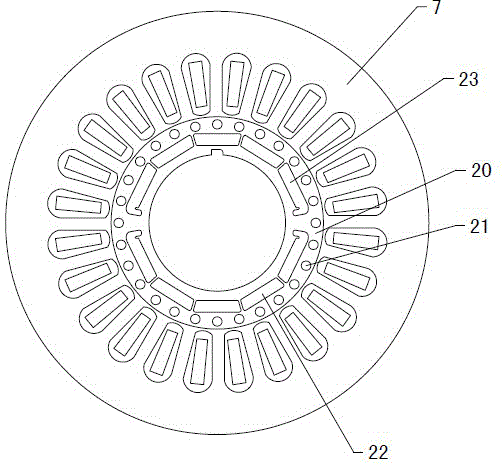

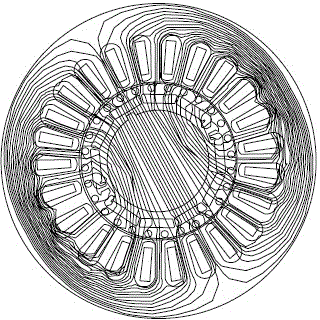

[0032] Figure 1~3 It is the best embodiment of the two-pole permanent magnet synchronous submersible motor, below in conjunction with the attached Figure 1~3 The present invention will be further described.

[0033] refer to Figure 1~3 , the two-pole permanent magnet synchronous submersible motor includes a stator 7 and a rotor 8 fixed in the casing 19, a motor shaft 9 is coaxially fixed inside the rotor 8, and the rotor 8 is a two-pole rotor composed of a plurality of magnetic steels, and the pole arc coefficient is 0.87, the rotor 8 includes a plurality of axially stacked rotor punches 20, and the outer circumference of the rotor punches 20 is uniformly provided with a plurality of starting rod fixing holes 21, and a plurality of starting rods are respectively fixed in the starting rod fixing holes 21 to form a starting In the squirrel cage, a plurality of N-pole magnetic steel fixing grooves 22 and a plurality of S-pole magnetic steel fixing grooves 23 are arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com