A Push-Pull Hanging Folding Sieve

A technology of push-pull type and push-pull rod, which is applied in the field of push-pull hanging folding screen and screening equipment, which can solve the problems of reduced screening efficiency, repeated pumping, short circuit of ore slurry, etc., achieves high degree of space utilization and reduces maintenance workload , The effect of wide feed concentration range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

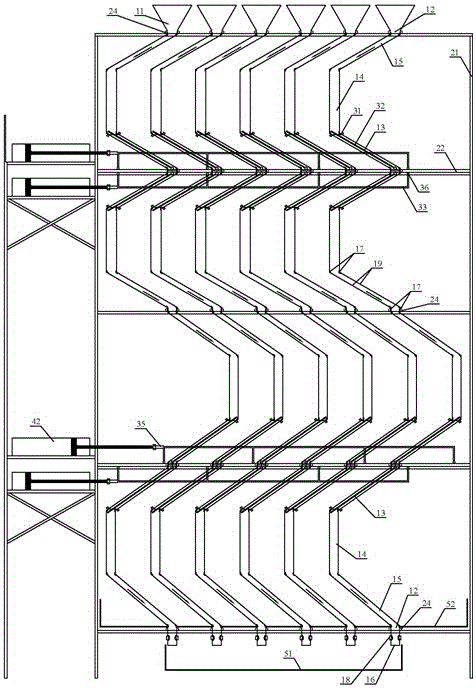

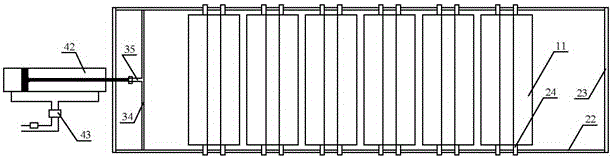

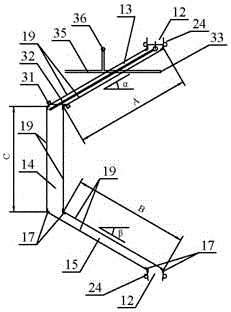

[0062] The push-pull hanging folding screen described in this embodiment is used for dewatering the pulp, including several screening units with the same string structure, frame, push-pull mechanism, transmission mechanism, bottom chute 51, support bottom groove 52 between strings, and splash screen 53, such as figure 1 , figure 2 As shown, the arrow in the figure indicates the flow direction of the slurry on the screen.

[0063] The screening unit includes an ore feeding chamber 11, a static chamber 12, a moving screen chamber group, and a receiving chamber 16; each chamber of the screening unit is a hollow communication structure surrounded by sides, and vertically The dynamic screen cavity group is set up in sections, and the static cavity 12 is set between the dynamic screen cavity group and the dynamic screen cavity group, between the dynamic screen cavity group and the ore feeding cavity 11, and between the dynamic screen cavity group and the receiving cavity 16; The...

Embodiment 2

[0102] The push-pull hanging folding screen described in this embodiment is used for wet screening, and includes several series screening units, racks, push-pull mechanisms, transmission mechanisms, machine bottom chute 51, string support bottom groove 52, splash screen 53, and water lines, such as Figure 12 As shown, the arrow indicates the flow direction of the slurry on the screen.

[0103] Compared with the first embodiment, for the description of the structure of the second push-pull hanging and folding screen, only the differences in factors and the addition of water adding pipelines are considered, and the similarities will not be repeated. The difference in consideration is that the slurry in the moving screen cavity group can be diluted according to the wet screening process, and the screen surface inclination angle of the active swinging screen cavity and the driven swinging screen cavity in the calibrated state is drawn up.

[0104] According to the application oc...

Embodiment 3

[0111] The push-pull hanging folding sieve described in this embodiment is used for immersion in water for wet screening, and includes several series screening units, racks, push-pull mechanisms, transmission mechanisms, bottom chute 51, support bottom groove 52 between series, splash-proof Curtain 53, and water adding pipeline, as Figure 14 As shown, the arrow indicates the flow direction of the slurry on the screen.

[0112] Compared with Embodiment 1 and Embodiment 2, the structural description of the third type of push-pull hanging and folding screen differs in that: the supporting bottom groove between the strings and the moving screen chamber group are arranged vertically one-to-one to prevent The splash curtain and the bottom slots between the strings are arranged one-to-one, thereby increasing and increasing the bottom slots between the strings to store the ore pulp. The splash curtain is segmented with the number of bottom slots between the strings and The height of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com