Hole drilling and edge cutting dual-purpose machine

An edge trimming and dual-purpose technology, applied in metal processing and other directions, can solve the problems of high maintenance cost, high assembly cost, long assembly time, etc., and achieve the effect of improving operation stability, ensuring processing accuracy and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

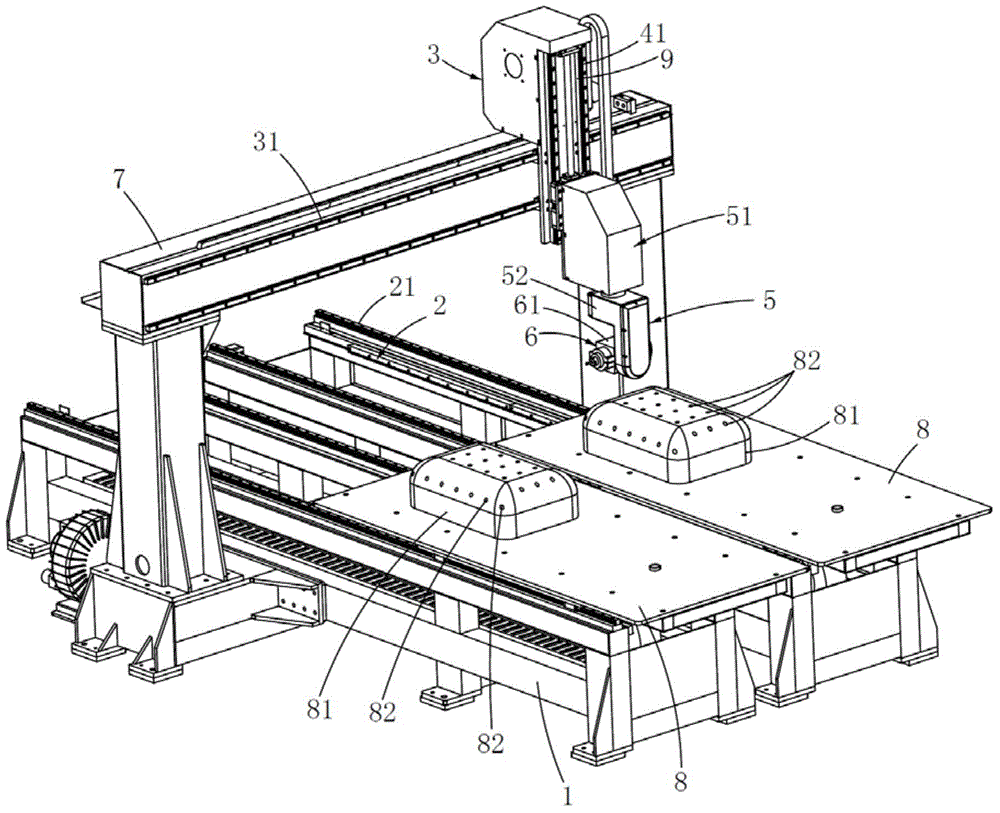

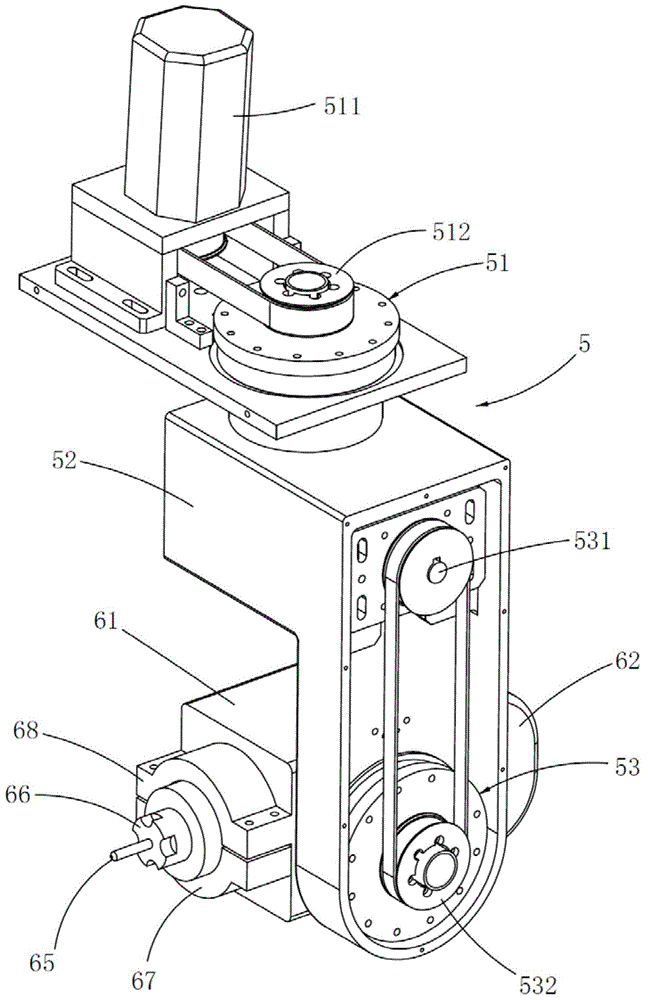

[0049] A six-axis drilling and trimming dual-purpose machine, see Figure 1 to Figure 6 As shown, it includes frame 1, Y-axis transmission mechanism 2, X-axis transmission mechanism 3, Z-axis transmission mechanism 4, double rocker arm mechanism 5, drilling edge trimming mechanism 6, vacuum device, gantry frame 7 and workbench 8 , The gantry 7 is fixed on the frame 1, the gantry 7 spans over the workbench 8, the X-axis transmission mechanism 3 is installed on the gantry 7, and the Z-axis transmission mechanism 4 is installed on the X-axis transmission mechanism 3.

[0050] The frame 1 is provided with two workbenches 8, and the two workbenches 8 are installed side by side in parallel. The frame 1 is equipped with two sets of Y-axis guide rails 21 and two sets of Y-axis transmission mechanisms 2, and one set of Y-axis guide rails 21 A workbench 8 is slidably installed, and two sets of Y-axis transmission mechanisms 2 are respectively connected to two workbenches 8, and the two ...

Embodiment 2

[0061] A five-axis drilling and trimming dual-purpose machine, see Figure 7 As shown, the main structure, principle and effect of this embodiment are the same as those of Embodiment 1, and will not be repeated here. The difference is that, compared with Embodiment 1, this embodiment reduces a worktable 8, which is a five-axis Drilling and trimming dual-purpose machine, specifically, the frame 1 is provided with a worktable 8, the frame 1 is installed on a set of Y-axis guide rails 21 and a set of Y-axis transmission mechanism 2, and the workbench 8 is slidably installed on the Y-axis The shaft guide slide rail 21 slides, the Y-axis transmission mechanism 2 is connected to the workbench 8, and the workbench 8 moves under the gantry 7 along the positive and negative directions of the Y-axis.

Embodiment 3

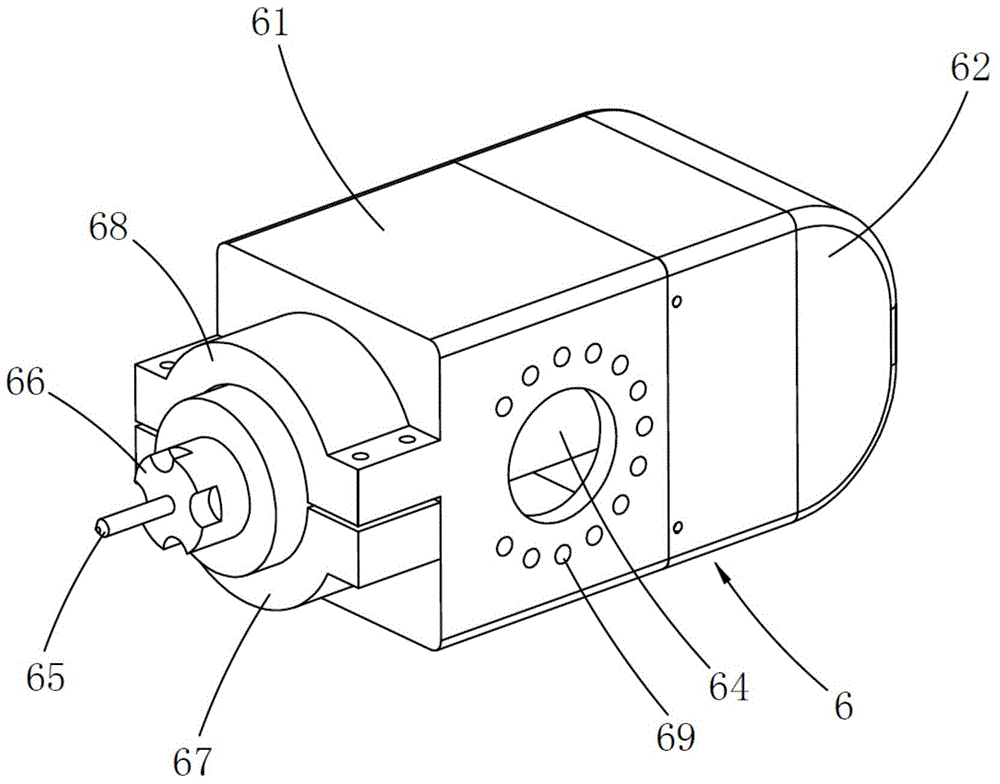

[0063] A four-axis drilling and trimming dual-purpose machine, see Figure 8 As shown, the main structure, principle and effect of this embodiment are the same as those of Embodiment 2, and will not be repeated here. 9. A fourth-axis rotation transmission mechanism 51 is installed, and the bottom of the fourth-axis rotation transmission mechanism 51 is connected with a drilling and edge trimming mechanism 6. The drilling and edge trimming mechanism 6 is provided with an integrated casing 61, a rear cover 62 and a drilling hole that are cast into one body. Cutting components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com