A low-floor tram bogie

A technology for trams and bogies, applied in the direction of bogies, devices for lateral relative movement between the underframe and the bogies, railway car body parts, etc., can solve the problem of heavy unsprung weight, poor mechanical performance, and driving The problems such as the huge weight of the motor and gear box can be avoided, so as to achieve the effect of stable installation, improved mechanical performance and reduced weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below with reference to the accompanying drawings.

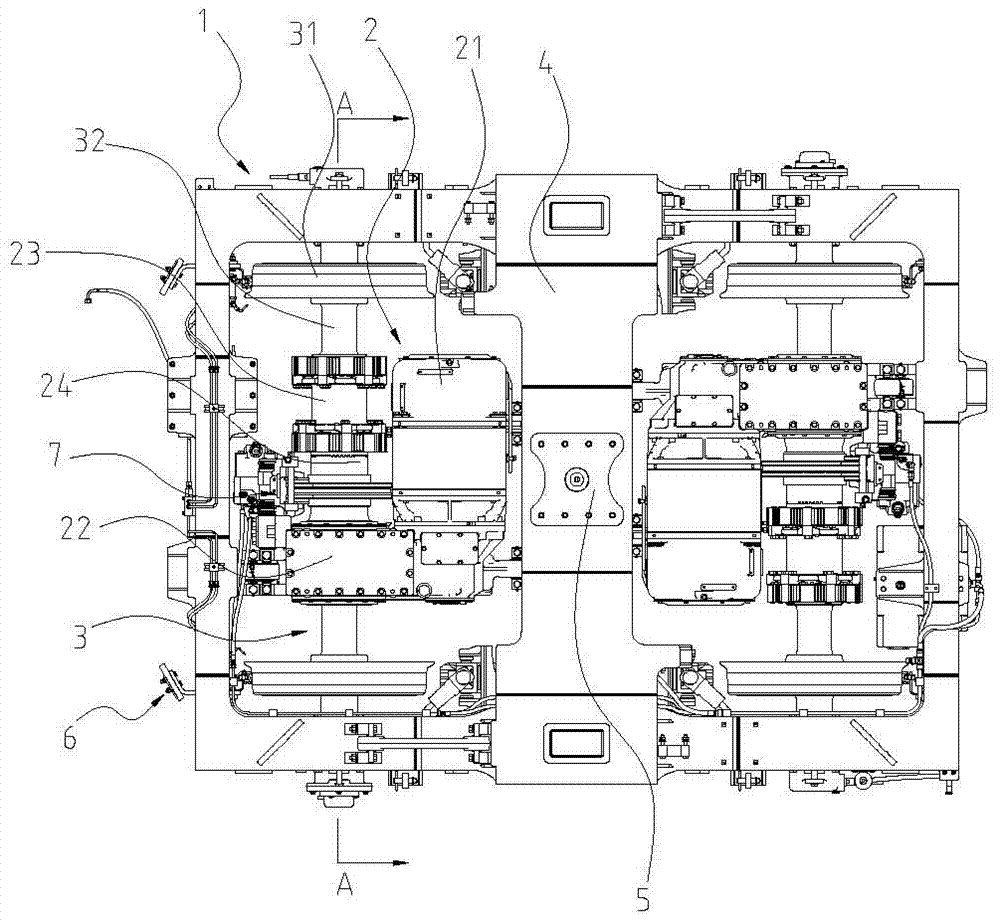

[0037] like figure 1 , 2 As shown, a low-floor tram bogie includes a frame 1, a bolster 4, a traction device 5 connected to the vehicle body 50, an axle box 8, a wheelset 3, a drive system 2, a braking system 7, and a primary suspension 91 , Second series suspension 92, stone sweeper and sand spreading device 6.

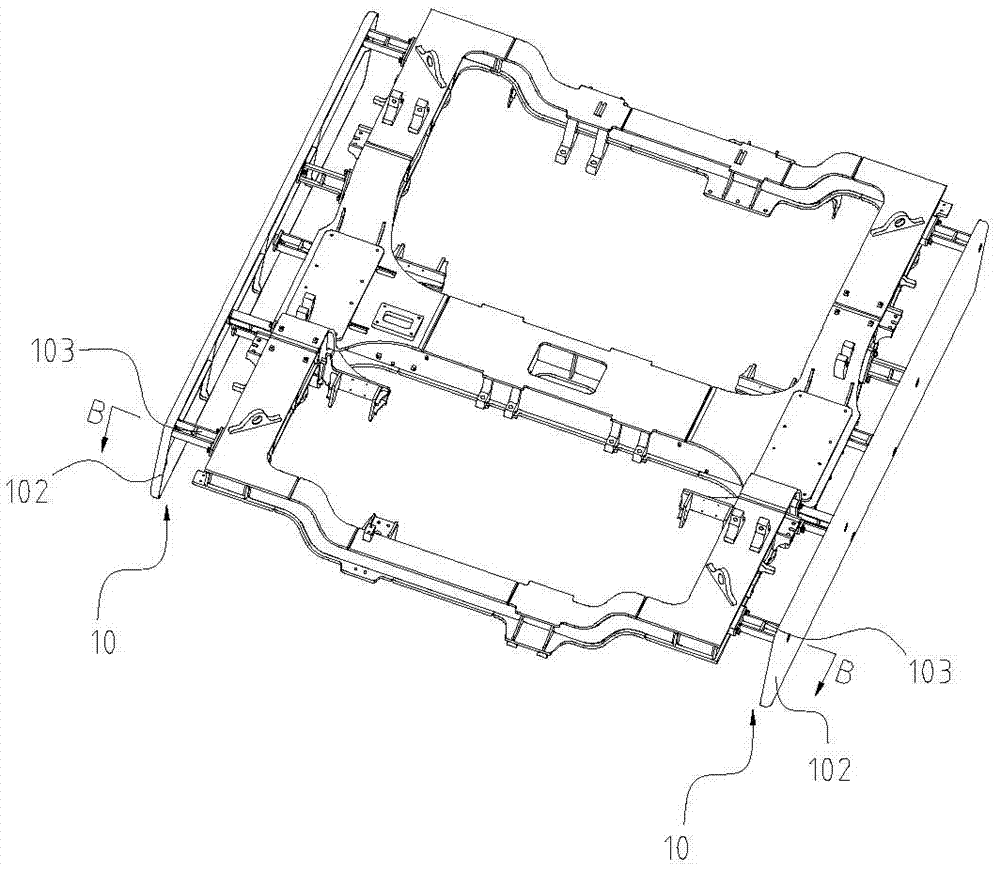

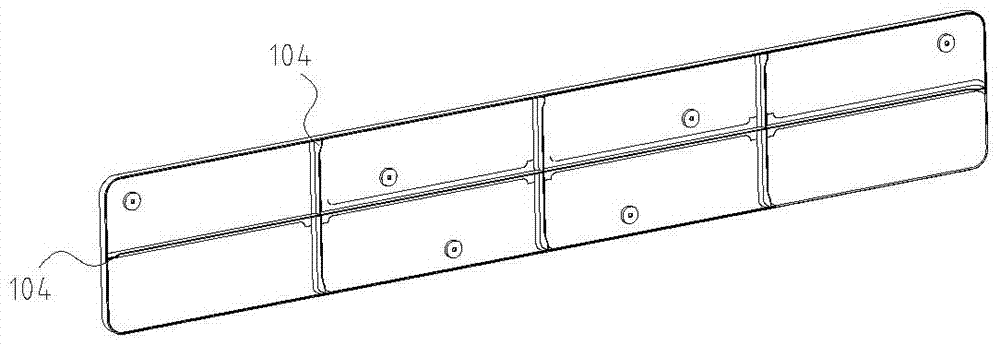

[0038] like Figure 4 , 5 As shown, the frame 1 is in the shape of a "Sun", which includes two symmetrically arranged side beams 11 , a cross beam 16 and an end beam 12 located between the two side beams 11 . The side beam 11 is in the shape of an airfoil, and includes a U-shaped frame 111 in the middle position and end frames 112 connected to both ends of the U-shaped frame 111. The connection between the end frame 112 and the U-shaped frame 111 is arc-shaped to enhance the connection. The strength of the upper part can reduce stress concentration; the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com