Preparation method of efficient organic matter

An organic, high-efficiency technology that can be used in the preparation of organic fertilizers, organic fertilizers, and bio-organic parts treatment, etc., and can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

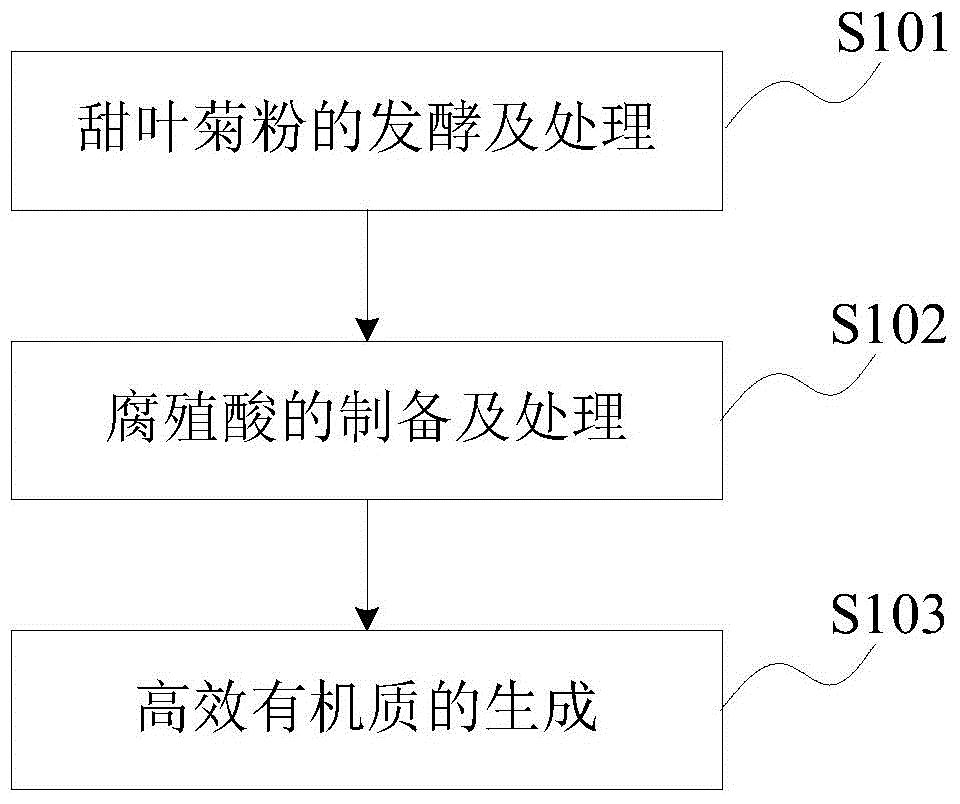

[0017] See figure 1 , The present invention provides a method for preparing high-efficiency organic matter, which includes:

[0018] Step S101: Fermentation and treatment of stevia powder: add a predetermined amount of stevia powder to the 2kg / t compound fermentation bacteria and a certain proportion of water and put it into the fermentation tank, stir to make the mixing uniform, and control the water content in the fermentation tank. Within the range of 45wt%, stir once every 3 days, after 20 days of fermentation at 20°C, turn to the sun to reduce water, crush, and pass through a 70-mesh sieve;

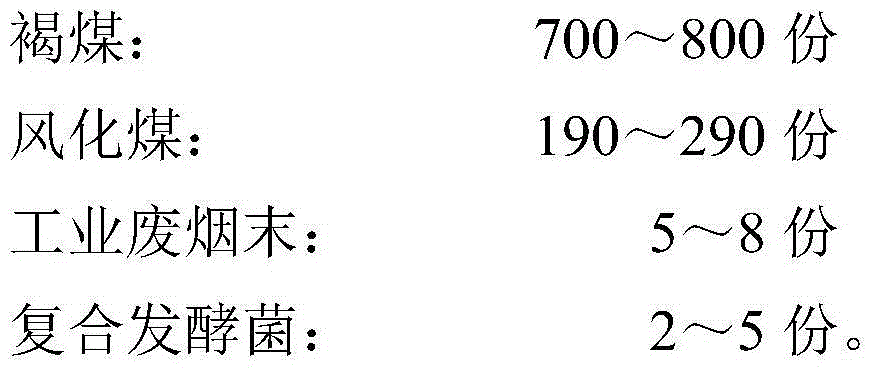

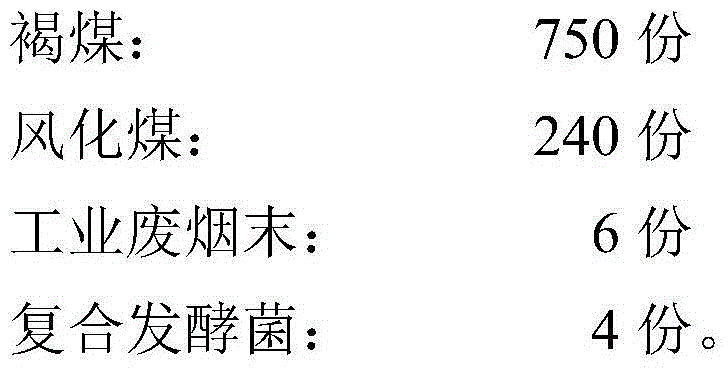

[0019] Step S102, preparation and treatment of humic acid: After pulverizing lignite, weathered coal and industrial waste smoke through a 70-mesh sieve, they are mixed evenly according to a predetermined ratio and piled into a cone, covered with a ventilated plastic film to control the fermentation temperature Turn the pile every 2 days at a temperature of 50°C. After turning the pile 3 ...

Embodiment 2

[0025] Fermentation and treatment steps of stevia powder: add a predetermined amount of stevia powder to 2.5kg / t of compound fermentation bacteria and a certain proportion of water and put it into the fermentation tank, stir to make the mixing uniform, the water content in the fermentation tank is 50wt%, Stir once every 4 days. After fermentation at 20°C for 25 days, turn to the sun to reduce water, crush, and pass through a 70-mesh sieve;

[0026] Preparation and treatment steps of humic acid: After crushing lignite, weathered coal and industrial waste smoke through a 70-mesh sieve, mix them evenly according to a predetermined ratio, pile them into a cone, and cover a layer of ventilated plastic film. The fermentation temperature is 55℃ Turn the pile every 2 days. After turning the pile 3 times, the fermentation temperature is 47℃, and the pile is turned once every 3 days. After keeping the fermentation for 45 days, the fermentation is over. After removing the covering film, air-...

Embodiment 3

[0031] Fermentation and treatment steps of stevia powder: add a predetermined amount of stevia powder to 3kg / t of compound fermentation bacteria and a certain proportion of water and put it into the fermentation tank, stir to mix evenly, the water content in the fermentation tank is 55wt%, Stir once every 5 days. After fermentation at 20°C for 30 days, turn to the sun to reduce water, crush, and pass through a 70-mesh sieve;

[0032] The preparation and treatment steps of humic acid: After crushing lignite, weathered coal and industrial waste smoke through a 70-mesh sieve, mix them evenly according to a predetermined ratio and pile them into a cone, covered with a layer of ventilated plastic film, and the fermentation temperature is 65℃ Turn the pile every 2 days. After turning the pile 3 times, control the fermentation temperature to 50℃, turn the pile every 3 to 4 days, keep the fermentation for 50 days and then the fermentation is over. Remove the cover film and air-dry it afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com