Connecting member for mounting of spring supports and hangers and manufacturing method of connecting member

A support and hanger and installation technology, which is applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of easy corrosion, aging, short service life, inconvenient maintenance and other problems at the interface, and achieve high temperature Anti-oxidation performance, avoiding the internal loosening of the tissue, and reducing the effect of grinding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

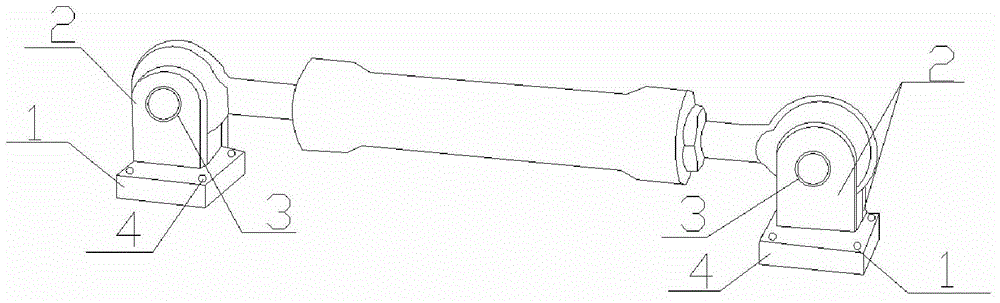

[0038] This embodiment provides a spring hanger installation connector, the structure is as follows figure 1 As shown, it includes a base 1 and a support frame 2, the support frame 2 is symmetrically arranged on the base 1, the support frame 2 and the base 1 form a U-shaped groove, and the support frame 2 is provided with a threaded hole 3, and the base 1 It is a cuboid structure, the four corners of the base 1 are provided with fixing holes 4, and the surface of the support frame 2 is coated with a zinc layer, wherein:

[0039] The base 1 and the support frame 2 are made of the same material, and the material for making the base 1 and the support frame 2 includes the following components in terms of mass percentage:

[0040]Cr: 1%, Mo: 0.8%, C: 0.04%, Co: 0.02%, Mn: 0.8%, P: 0.030%, S: 0.03%, Ni: 0.6%, Ti: 0.04%, W: 0.2%, V: 0.08%, Cu: 0.4%, Si: 0.8%, Nb: 0.05%, Ta: 0.02%, N: 0.02%, Mg: 0.03%, rare earth elements: 0.15%, and the rest are Fe and unavoidable impurities;

[00...

Embodiment 2

[0054] This embodiment provides a spring hanger installation connector, the structure is as follows figure 1 As shown, it includes a base 1 and a support frame 2, the support frame 2 is symmetrically arranged on the base 1, the support frame 2 and the base 1 form a U-shaped groove, and the support frame 2 is provided with a threaded hole 3, and the base 1 It is a cuboid structure, the four corners of the base 1 are provided with fixing holes 4, and the surface of the support frame 2 is coated with a zinc layer, wherein:

[0055] The base 1 and the support frame 2 are made of the same material, and the material for making the base 1 and the support frame 2 includes the following components in terms of mass percentage:

[0056] Cr: 2%, Mo: 0.9%, C: 0.02%, Co: 0.04%, Mn: 0.5%, P: 0.028%, S: 0.01%, Ni: 0.5%, Ti: 0.03%, W: 0.3%, V: 0.06%, Cu: 0.3%, Si: 0.5%, Nb: 0.03%, Ta: 0.04%, N: 0.01%, Mg: 0.04%, rare earth elements: 0.18%, and the rest are Fe and unavoidable impurities;

[0...

Embodiment 3

[0070] This embodiment provides a spring hanger installation connector, the structure is as follows figure 1 As shown, it includes a base 1 and a support frame 2, the support frame 2 is symmetrically arranged on the base 1, the support frame 2 and the base 1 form a U-shaped groove, and the support frame 2 is provided with a threaded hole 3, and the base 1 It is a cuboid structure, the four corners of the base 1 are provided with fixing holes 4, and the surface of the support frame 2 is coated with a zinc layer, wherein:

[0071] The base 1 and the support frame 2 are made of the same material, and the material for making the base 1 and the support frame 2 includes the following components in terms of mass percentage:

[0072] Cr: 3%, Mo: 1.0%, C: 0.03%, Co: 0.05%, Mn: 0.6%, P: 0.025%, S: 0.02%, Ni: 0.55%, Ti: 0.05%, W: 0.4%, V: 0.05%, Cu: 0.2%, Si: 0.2%, Nb: 0.04%, Ta: 0.06%, N: 0.015%, Mg: 0.02%, rare earth elements: 0.17%, and the rest are Fe and unavoidable impurities;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com