Online simultaneous monitoring sensor and online simultaneous monitoring method for COD (Chemical Oxygen Demand) and nitrogen content of nitrate

A nitrate nitrogen, sensor technology, applied in the field of sensors, can solve the problems of secondary pollution, poor stability, poor integration, etc., and achieve the effects of no need for preheating, improved performance, and increased wavelength range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

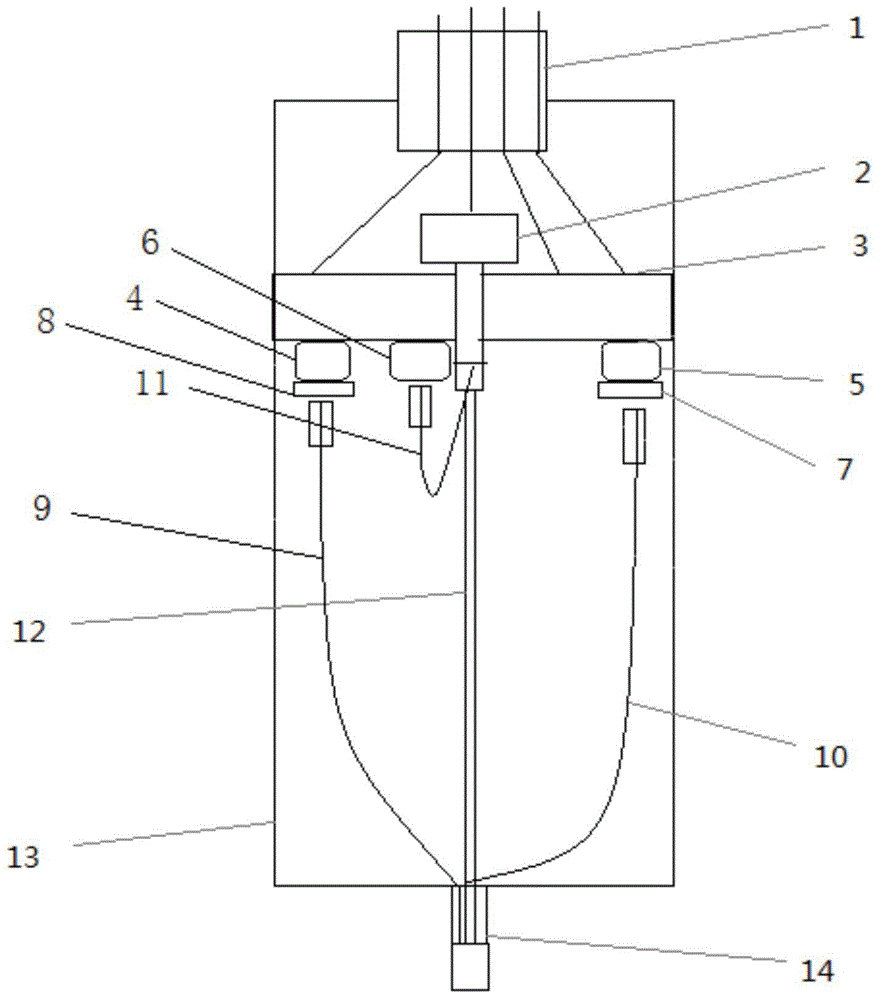

[0064] like figure 1 Shown: chemical oxygen demand provided by the present invention, nitrate nitrogen content multi-parameter online simultaneous monitoring sensor mainly is made up of following five parts: (one) light source module (ultraviolet light source-miniature deuterium lamp 2); (two) signal Acquisition and transmission module (waterproof connector 1, multi-channel signal acquisition circuit board 3, 1# photosensitive tube 4, 2# photosensitive tube 5, 3# photosensitive tube 6); (3) optical fiber module (refer to optical fiber 11, 254nm bandpass filter Light sheet 8, 210nm bandpass filter 7, 1# signal fiber 9, 2# signal fiber 10, light source fiber 12); (4) detection probe module (detection probe 14), the above four modules are all encapsulated in a stainless steel shell In 14, optical signals are transmitted through optical fibers, and electrical signals are transmitted through shielded cables. The mini deuterium lamp 2 (200nm-400nm) is coupled together with the lig...

Embodiment 2

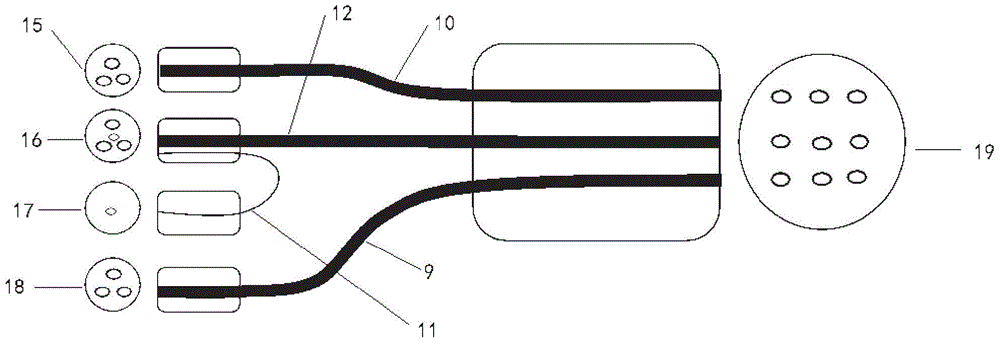

[0078] The optical fiber module and detection probe of the present invention are specially designed so that the sensor can simultaneously measure two parameters of COD and chemical oxygen demand with one probe.

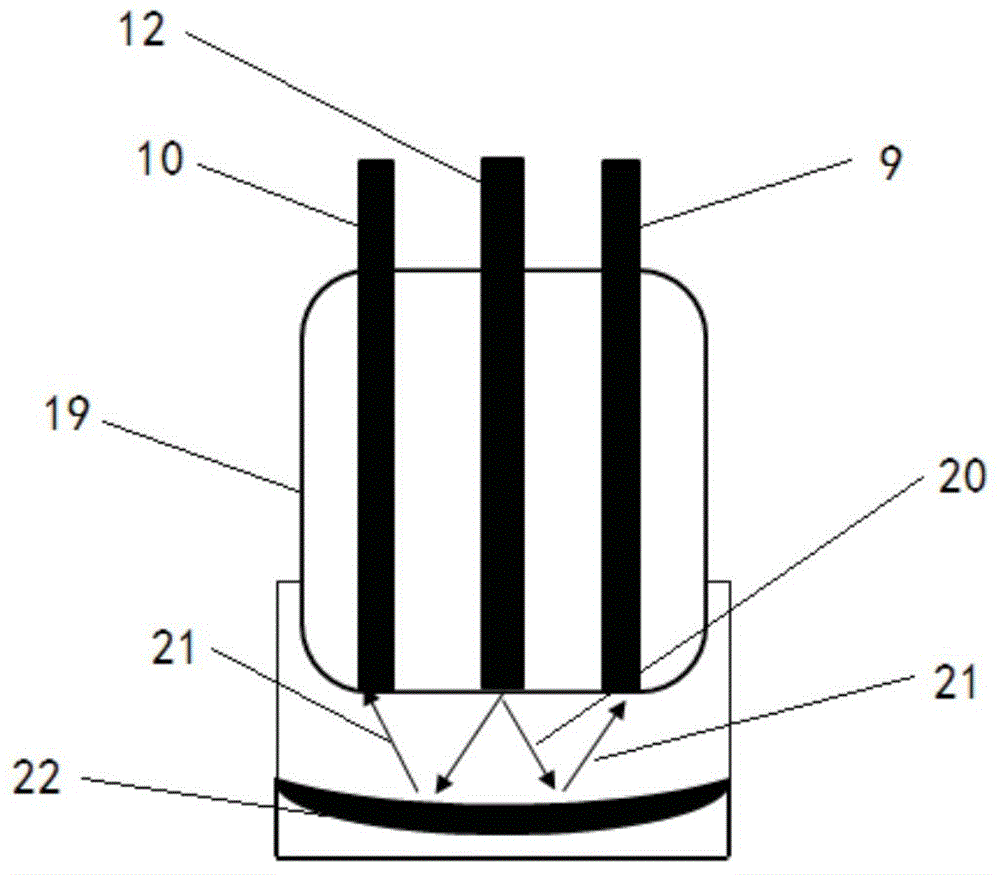

[0079] Fiber design such as figure 2 As shown, the optical fiber terminal 16 at the light source end has 4 cores, and three of them have a diameter of 400 μm, that is, the light source fiber 12. The light source fiber connects the light source end and the detection probe end, and provides an ultraviolet light source for the detection probe. The optical fiber 11 is connected to the reference optical terminal 17 to indicate whether the light source is working normally; the detection probe end optical fiber terminal 19 is 9 cores, and the diameter is 400 μm, three of which (being the light source optical fiber 12) are connected with the light source optical fiber terminal 16, and three ( That is, the 1# signal optical fiber 9) is connected to the 1# signal optical termin...

Embodiment 3

[0082] The application method of a multi-parameter online monitoring sensor for chemical oxygen demand and nitrate nitrogen content in actual water body detection in this embodiment. Proceed as follows:

[0083] Step 1: Calibrate the sensor

[0084] (1) Prepare 10 standard water samples with different chemical oxygen demand in beakers as samples to be tested (concentration range 0.50mg / L)

[0085](2) Measure the 10 samples respectively by using the standard chemical oxygen demand measurement method and instrument, and obtain the standard value of the chemical oxygen demand of the samples.

[0086] (3) Sensor of the present invention is inserted in 10 sample solutions respectively, power-on test, record the absorbance value that 1# photosensitive tube 4 records, and it and sample chemical oxygen demand standard value fitting establish linear relationship, as Figure 4 As shown, the correction formula Y is obtained 1 =358.50966*X 1 -31.85428, the complex correlation coeffici...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com