Electrochromic intelligent glass and manufacturing method thereof

A smart glass, electrochromic technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of undeveloped application potential of electrochromic glass, poor uniformity and stability, and low visual comfort. Control and optimization, good uniformity, improved visual comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

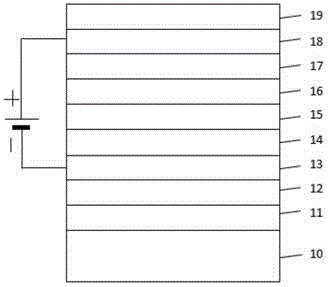

[0030] Such as figure 1 As shown, a kind of electrochromic smart glass of the present invention, it comprises substrate 10, on substrate 10 successively is the first anti-reflection layer 11, the second anti-reflection layer 12, the first transparent conductive layer 13, Electrochromic layer 14 , ion conductive layer 15 , ion storage layer 16 , ion layer 17 , second transparent conductive layer 18 and third antireflection layer 19 .

[0031] in:

[0032] The substrate 10 is ordinary glass with a thickness of 4mm.

[0033] The thickness of the first anti-reflection layer 11 is 20 nanometers, and its composition is the oxide of niobium (Nb 2 o 3 ).

[0034] The thickness of the second anti-reflection layer 12 is 18 nanometers, and its composition is the oxide of titanium (TiO 2 ).

[0035] The thickness of the first transparent conductive layer 13 is 400 nm, and its composition is indium tin oxide (ITO).

[0036] The thickness of electrochromic layer 14 is 300 nanometers, a...

Embodiment 2

[0045] Such as figure 1 Shown, a kind of electrochromic smart glass of the present invention, it comprises substrate 10, in such as figure 1 As shown, a kind of electrochromic smart glass of the present invention, it comprises substrate 10, on substrate 10 successively is the first anti-reflection layer 11, the second anti-reflection layer 12, the first transparent conductive layer 13, Electrochromic layer 14 , ion conductive layer 15 , ion storage layer 16 , ion layer 17 , second transparent conductive layer 18 and third antireflection layer 19 .

[0046] in:

[0047] The substrate 10 is ordinary glass with a thickness of 6 mm.

[0048] The thickness of the first anti-reflection layer 11 is 18 nanometers, and its composition is the oxide of alum (V 2 o 5 ).

[0049] The thickness of the second anti-reflection layer 12 is 18 nanometers, and its composition is the oxide of titanium (TiO 2 ).

[0050] The thickness of the first transparent conductive layer 13 is 450 nm, a...

Embodiment 3

[0059] Such as figure 1 As shown, a kind of electrochromic smart glass of the present invention, it comprises substrate 10, on substrate 10 successively is the first anti-reflection layer 11, the second anti-reflection layer 12, the first transparent conductive layer 13, Electrochromic layer 14 , ion conductive layer 15 , ion storage layer 16 , ion layer 17 , second transparent conductive layer 18 and third antireflection layer 19 .

[0060] in:

[0061] The substrate 10 is ordinary glass with a thickness of 5 mm.

[0062] The thickness of the first anti-reflection layer 11 is 16 nanometers, and its composition is the oxide of niobium (Nb 2 o 3 ).

[0063] The thickness of the second anti-reflection layer 12 is 21 nanometers, and its composition is the oxide of titanium (TiO 2 ).

[0064] The thickness of the first transparent conductive layer 13 is 350 nm, and its composition is aluminum-doped zinc oxide (AZO).

[0065] The thickness of electrochromic layer 14 is 450 n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com