Tilapia fillet antistaling agent and utilization method thereof

A tilapia fillet and antistaling agent technology, which is applied in the direction of preserving meat/fish with chemicals, can solve problems such as difficulty in ensuring food safety, and achieve the effects of safe use, food safety, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Preparation of antistaling agent for tilapia fillets: take 5g and 10g of Asparagus oligosaccharides, prepare 0.5%, 1.0% Asparagus oligosaccharides aqueous solution, fully stir evenly, so that the powder is completely dissolved, and the color of the solution is uniform;

[0030] 2) Pre-cooling treatment with antistaling agent for tilapia fillets: pre-cool water, 0.5% asparagus oligosaccharide solution and 1.0% asparagus oligosaccharide solution to lower the temperature to 0-4°C;

[0031] 3) Fresh-keeping treatment of tilapia fillets: soak tilapia fillets in water, 0.5% and 1.0% asparagus oligosaccharide solutions respectively, the material-liquid ratio (w:v) of fish fillets to preservative is 1:3, soak The time is 30 minutes;

[0032] 4) Preservation of the finished product: soak the fish fillets in step 3), dry them at 4°C, pack them in fresh-keeping bags, and store them at 4°C.

Embodiment 2

[0034] 1) Preparation of antistaling agent for tilapia fillets: mix asparagus oligosaccharides, citric acid and tea polyphenols according to the following weight components: 45% asparagus oligosaccharides, 35% citric acid, and 20% tea polyphenols. Mix the above ingredients and prepare a 1.0% aqueous solution to obtain a compound preservative. Stir well to make the powder completely dissolve and the color of the solution is uniform;

[0035] 2) Pre-cooling treatment of tilapia fillet preservative: pre-cool water and compound preservative to lower the temperature to 4°C;

[0036] 3) Fresh-keeping treatment of tilapia fillets: Soak the tilapia fillets in water and compound preservative respectively, the material-liquid ratio (w:v) of the fish fillets to the preservative is 1:3, and the soaking time is 30 minutes;

[0037] 4) Preservation of the finished product: soak the fish fillets in step 3), dry them at 4°C, pack them in fresh-keeping bags, and store them at 4°C.

Embodiment 3

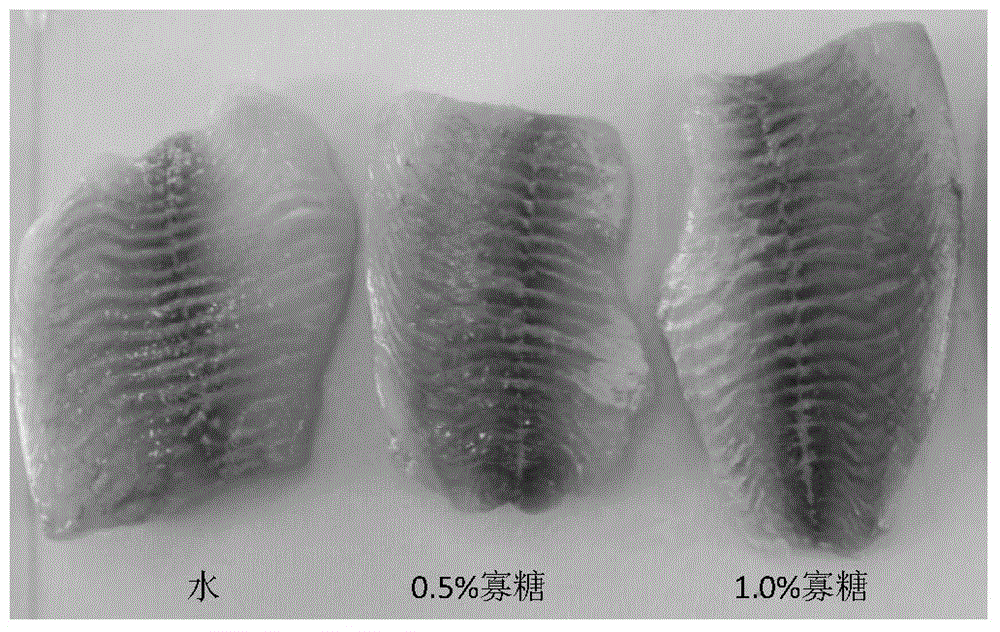

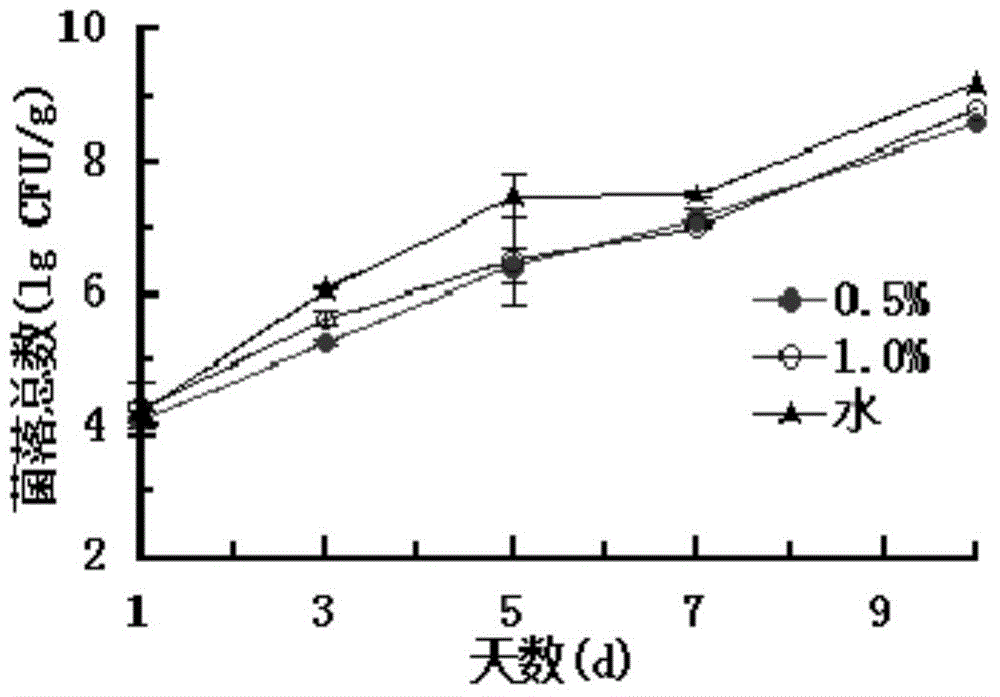

[0039] 1) Treat according to the steps in Example 1 to obtain 0.5% and 1.0% asparagus oligosaccharide group tilapia fillets respectively, set aside, take fresh tilapia fillets of the same size at the same time, put them in 4 ° C pre-cooled water for 30 minutes , take it out and dry it naturally in a 4°C freezer, then pack it in a fresh-keeping bag, store it at 4°C, and set it aside;

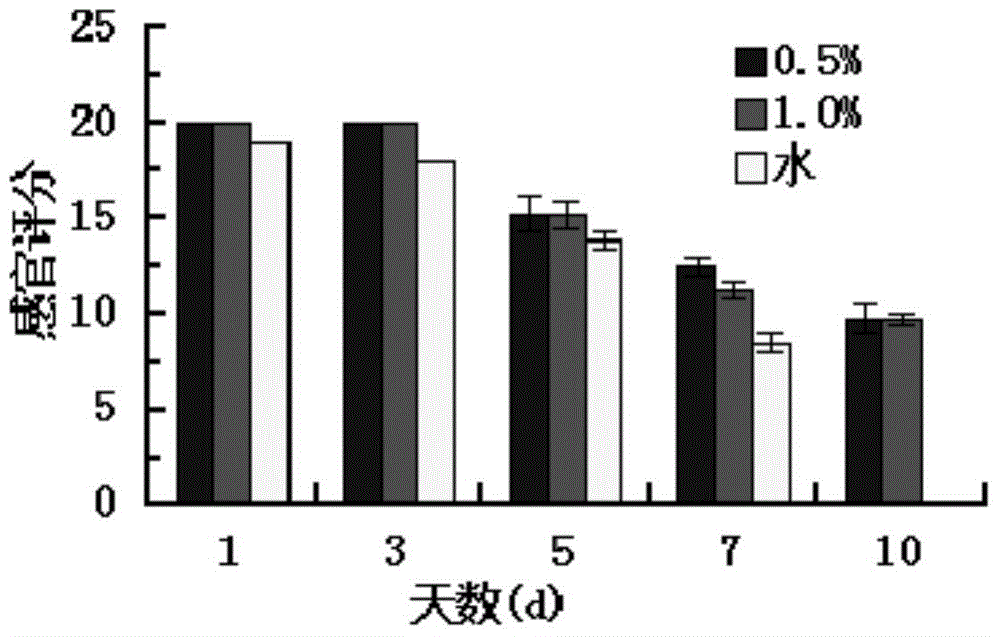

[0040] 2) Sensory evaluation: Observe the tilapia fillets refrigerated under 4°C storage conditions at regular intervals, and perform sensory evaluation from four aspects: color, smell, tissue shape, and muscle elasticity, and each sensory evaluation result is between 0 and 5. Between points, 5 points for a full score. The sensory evaluation panel consisted of 5 experienced evaluators.

[0041] The tilapia fillets without preservative treatment reached the sensory end point on the 6th day of storage, and the tilapia fillets treated with 0.5% or 1.0% asparagus oligosaccharides reached the sensory...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com