Frozen potato steamed stuffed buns and manufacturing method thereof

A production method and potato technology are applied in food preparation, yeast-containing food ingredients, food science, etc., which can solve the problems of incomplete nutritional supplementation, lack of carotene and vitamin C, etc., and achieve improved dietary nutritional structure, rich nutrition, and convenience. The effect of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

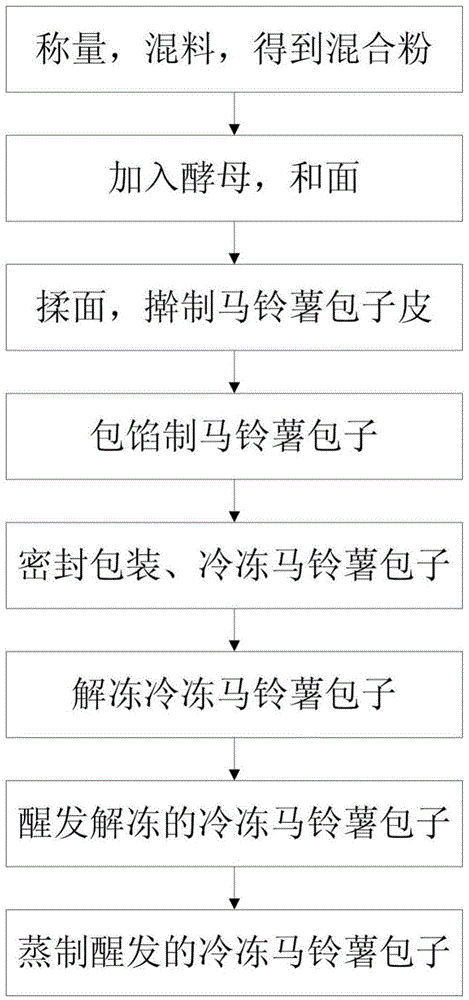

Method used

Image

Examples

Embodiment 1

[0053] A kind of frozen potato steamed bun, it is made of potato steamed bun skin and steamed bun stuffing; Wherein, described potato steamed bun skin comprises the component of following parts by weight:

[0054] 20 parts of whole potato flour, 40 parts of low-gluten flour, 0.5 parts of modified potato starch, 1.5 parts of gluten flour, 0.5 parts of trehalose, 0.5 parts of dry yeast, 0.5 parts of frozen dough improver and purified water at a temperature of 25-35 °C 80 copies;

[0055] Wherein, the mass ratio of the potato bun skin to the stuffing is 4.61:1;

[0056] Wherein, the whole potato powder is the whole potato powder pulverized by an ultrafine pulverizer, and the particle size of the pulverized whole potato powder is less than 120 mesh.

Embodiment 2

[0058] A kind of frozen potato steamed bun, it is made of potato steamed bun skin and steamed bun stuffing; Wherein, described potato steamed bun skin comprises the component of following parts by weight:

[0059] 30 parts of whole potato flour, 45 parts of low-gluten flour, 0.8 parts of modified potato starch, 2.0 parts of gluten flour, 1 part of trehalose, 1 part of dry yeast, 0.5 parts of frozen dough improver and 90 parts of purified water at 25-35 °C ;

[0060] Wherein, the mass ratio of the potato bun skin to the stuffing is 4.61-6.25:1;

[0061] Wherein, the whole potato powder is the whole potato powder pulverized by an ultrafine pulverizer, and the particle size of the pulverized whole potato powder is less than 120 mesh.

Embodiment 3

[0063] A kind of frozen potato steamed bun, it is made of potato steamed bun skin and steamed bun stuffing; Wherein, described potato steamed bun skin comprises the component of following parts by weight:

[0064] 40 parts of whole potato flour, 51 parts of low-gluten flour, 1.2 parts of modified potato starch, 2.5 parts of gluten flour, 1.5 parts of trehalose, 1.5 parts of dry yeast, 1 part of frozen dough improver and purified water at a temperature of 25-35 ℃ 150 copies;

[0065] Wherein, the mass ratio of the potato bun skin to the stuffing is 4.61-6.25:1;

[0066] Wherein, the whole potato powder is the whole potato powder pulverized by an ultrafine pulverizer, and the particle size of the pulverized whole potato powder is less than 120 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com