Detachable tracked vehicle with CVT and reverse

A continuously variable speed and detachable technology, which is applied to tracked vehicles, non-deflectable wheel steering, motor vehicles, etc., can solve the problems of reduced scope of application of tracked vehicles, heavy equipment weight, and difficulty in turning, so as to reduce volume and weight, The effect of the system running smoothly, easy to carry and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

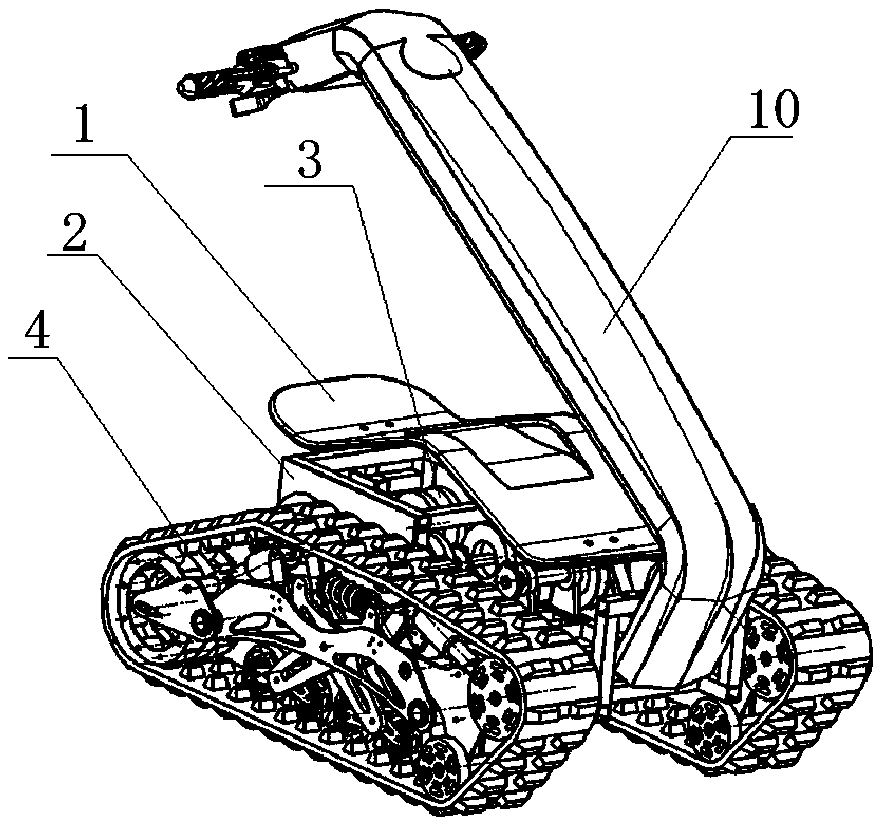

[0037] like figure 1 — Image 6 As shown, the detachable crawler vehicle with continuously variable speed and reverse gear of the present invention includes a pedal 1, a support frame 2, a drive assembly 3, a suspension assembly 4 and an operating rod 10, and the pedal 1 is arranged on the upper part of the support frame 2 , the support frame 2 is a frame structure, and a driving assembly 3 is provided at the inner cavity thereof, and the two sides of the support frame 2 are respectively provided with spline shafts for inserting a suspension assembly 4, and the suspension assembly 4 is two are respectively inserted on both sides of the support frame 2, and the operating rod 10 is arranged on the front side of the support frame 2.

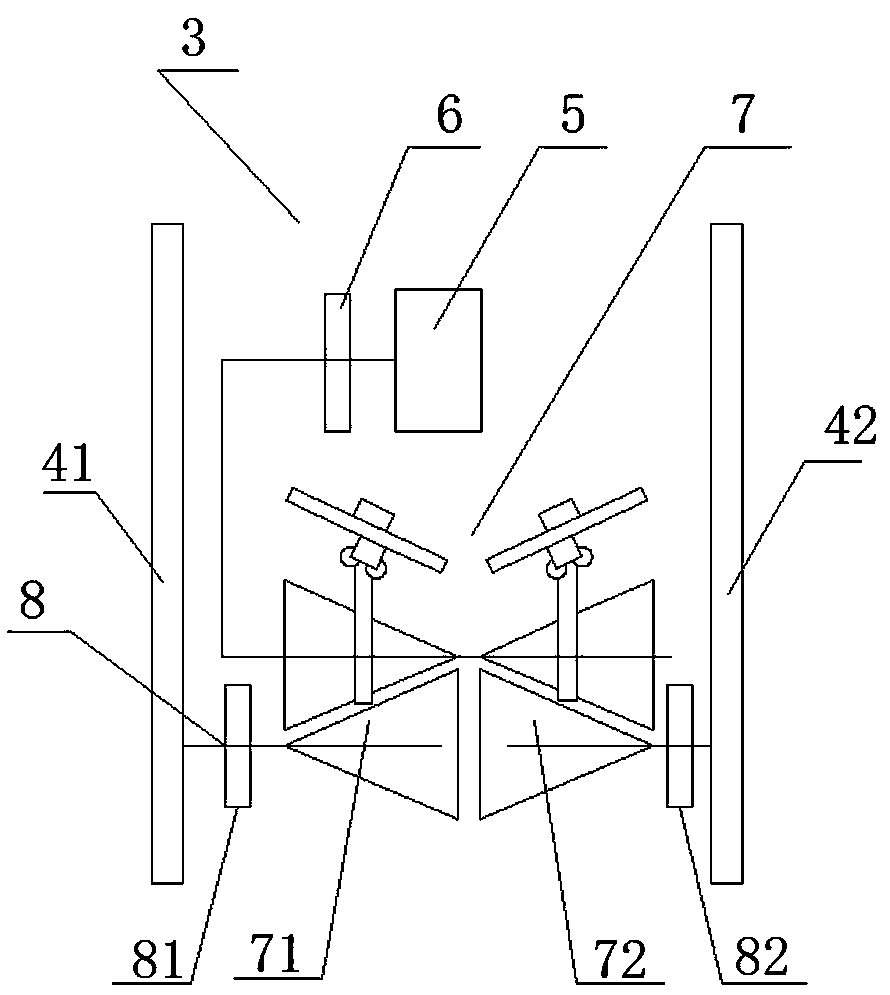

[0038] The driving assembly 3 includes a driving device 5, a starting device 6, a variable speed differential system 7 and a reversing system 8, the output shaft of the driving device 5 is connected with the starting device 6, and the output shaft ...

Embodiment 2

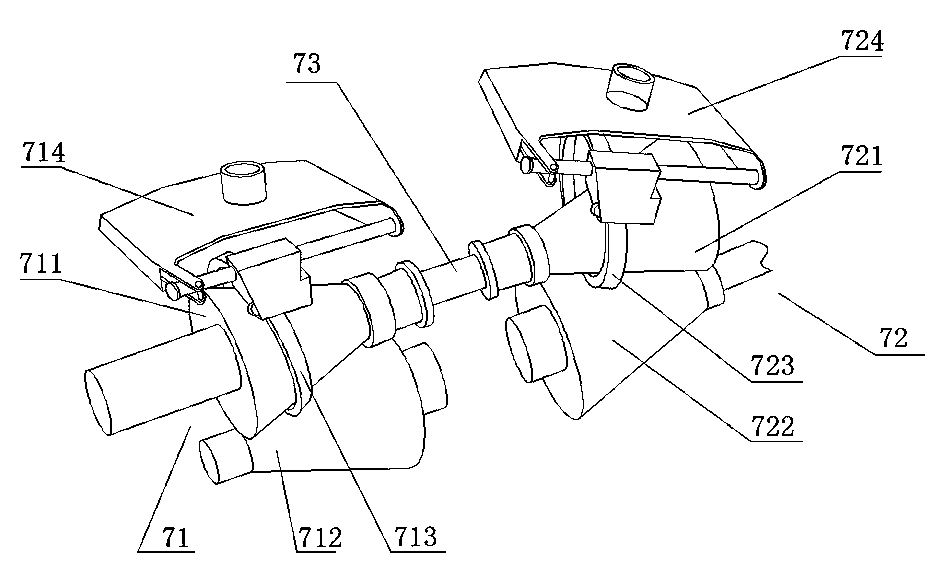

[0050] like figure 1 , image 3 , Image 6 and Figure 7 The difference between the second embodiment and the first embodiment is that the first reversing system 81 includes a forward guide wheel 86, a reversing wheel 87, a reverse guide wheel 88, a transmission wheel 89 and a drive shaft 80, and the forward guide wheel 86 is fixed At the tip of the first driven roller 712, the positive guide wheel 86 and the first driven roller 712 are all connected to the transmission shaft 80 through bearings, so the forward guide wheel 86 and the first driven roller 712 can be in the transmission Rotate freely on the shaft 80, the side of the positive guide wheel 86 away from the first driven roller cone 712 is provided with transmission teeth, the reverse guide wheel 88 is coaxially arranged with the forward guide wheel 86 and connected with the transmission shaft 80 through a bearing, The reverse guide wheel 88 is provided with transmission teeth near the side of the forward guide whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com