Removal method for purifying ethelene glycol monophenyl ether

A technology of ethylene glycol phenyl ether and isopropanol, which is applied in chemical instruments and methods, ether preparation, organic chemistry, etc., can solve the problems of high energy consumption, difficulty, and high production technology requirements, and achieve low energy consumption for refining, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

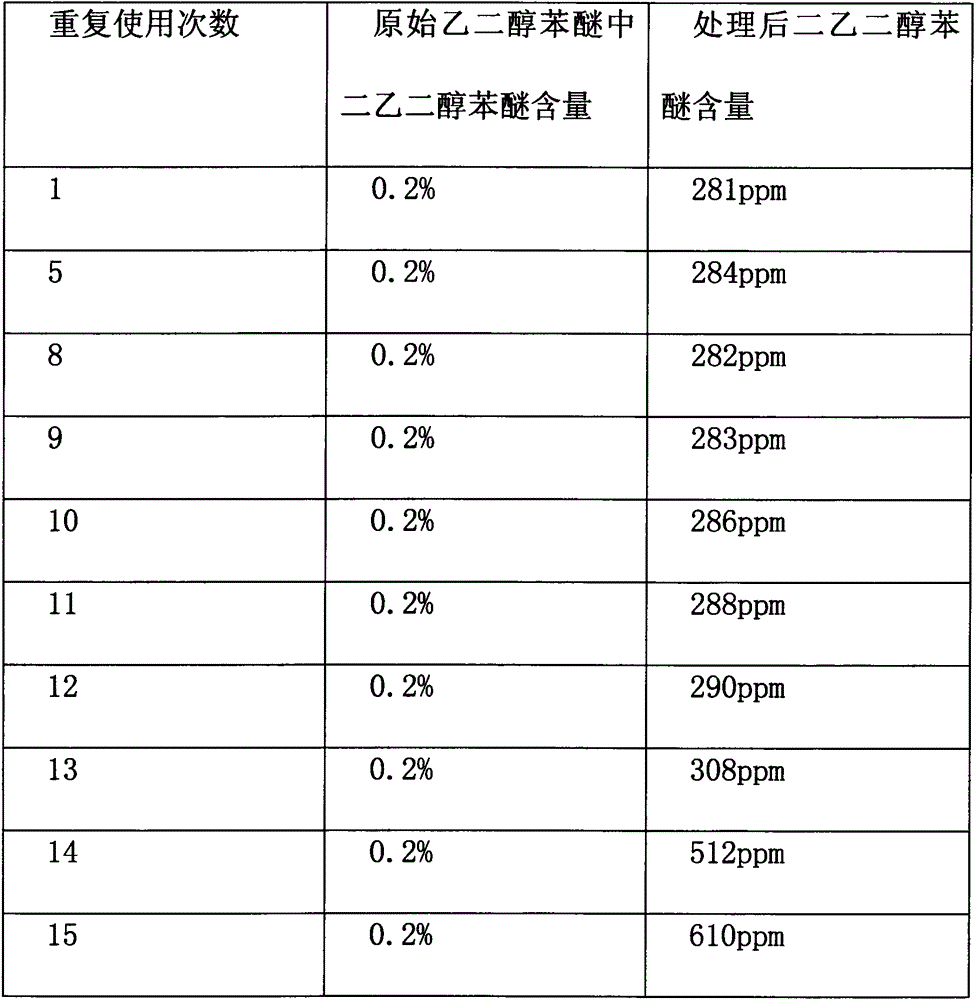

[0011] A removal method for purifying ethylene glycol phenyl ether, which uses a synthetic adsorption separation material (A) to disperse in ethylene glycol phenyl ether. Wherein the synthetic adsorption separation material (A) comprises:

[0012] (1) Use hydroxypropyl methylcellulose with a gelling temperature above 80° C., and use room temperature deionized water to prepare a 0.05% polymer solution. Dispersing calcium carbonate with a fineness of less than 700 meshes in the polymer solution, the amount of calcium carbonate is 10% of the amount of deionized water;

[0013] (2) Use an isopropanol solution with a mass concentration not higher than 7% aluminum isopropoxide, and add it to the aforementioned sol at room temperature in an equimolar ratio between aluminum isopropoxide and calcium carbonate;

[0014] (3) After the addition of aluminum isopropoxide is completed, slowly raise the temperature of this mixed system from room temperature to 50-65°C at a rate of no more th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com