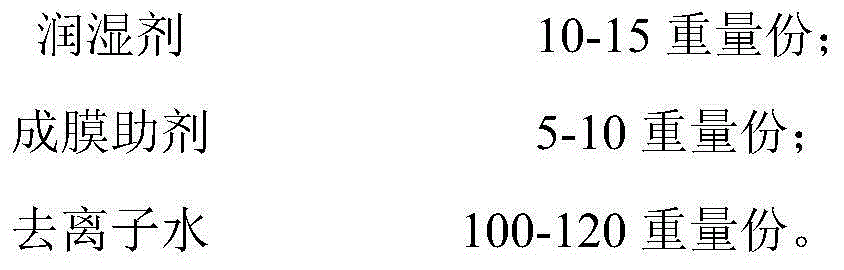

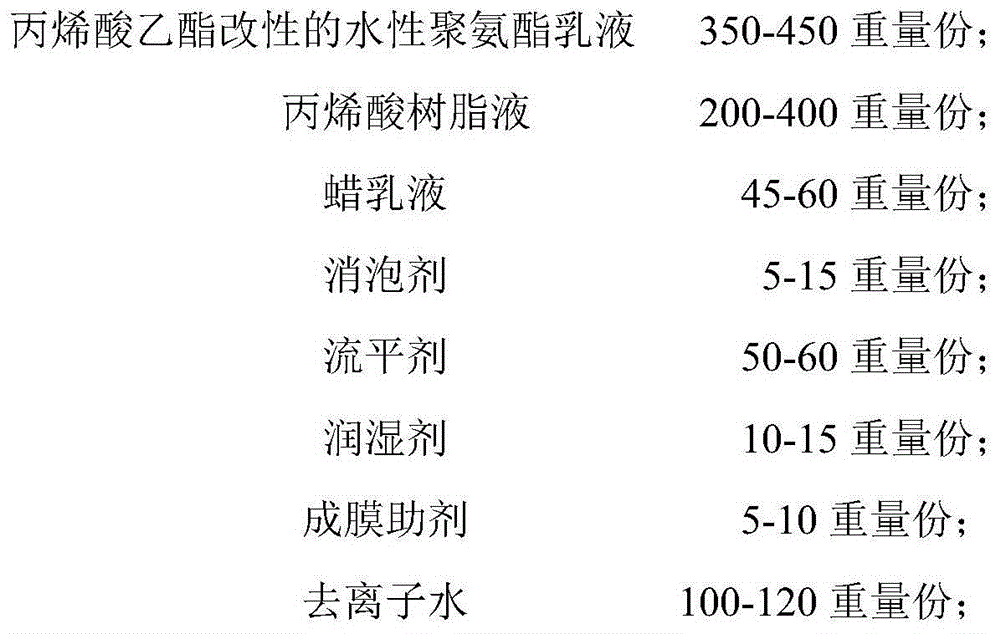

Environment-friendly high-glossiness waterborne gloss oil and method for manufacturing same

A water-based varnish, environmentally friendly technology, applied in the direction of coating, can solve the problem of insufficient gloss and environmental protection, and achieve the effect of high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

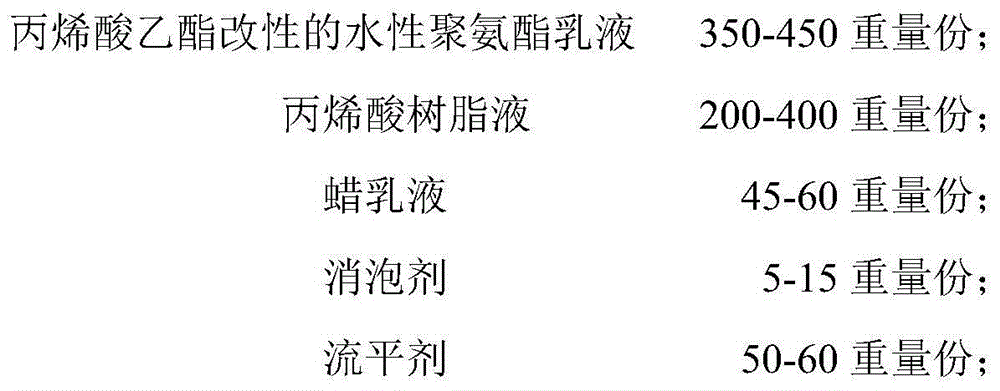

[0035] The parts by weight of the components of the glazing oil in this example are shown in Table 1.

[0036] Table 1 The parts by weight of each component of glazing oil in Example 1

[0037] components

parts by weight

Ethyl Acrylate Modified Waterborne Polyurethane Emulsion

400

Acrylic resin liquid S-2919

300

53

Tego 810 defoamer

10

Digo Glide100 leveling agent

55

Tego 245 wetting agent

12

Alcohol ester twelve film-forming aids

8

Deionized water

110

[0038] The preparation steps are as follows:

[0039] (1) Proportionally disperse the water-based polyurethane emulsion modified by ethyl acrylate and deionized water with a homogenizer for 30 minutes, and the homogenizer speed is 800r / min;

[0040] (2) Add the acrylic resin liquid to the mixture obtained in step (1), continue to disperse for 30 minutes with a homogenizer, and the homogenizer speed is...

Embodiment 2

[0047] The parts by weight of the components of the glazing oil in this example are shown in Table 3.

[0048] Table 3 The parts by weight of each component of glazing oil in Example 2

[0049] components

parts by weight

Ethyl Acrylate Modified Waterborne Polyurethane Emulsion

350

Acrylic resin liquid S-2919

200

BASF Wax Emulsion

45

Tego 810 defoamer

5

Digo Glide100 leveling agent

50

Tego 245 wetting agent

10

Alcohol ester twelve film-forming aids

5

Deionized water

100

[0050] The preparation steps are as follows:

[0051] (1) Proportionally disperse the water-based polyurethane emulsion modified by ethyl acrylate and deionized water with a homogenizer for 20 minutes, and the homogenizer speed is 750r / min;

[0052] (2) Add the acrylic resin liquid to the mixture obtained in step (1), continue to disperse for 30 minutes with a homogenizer, and the homogenizer speed is ...

Embodiment 3

[0059] The parts by weight of each component of the glazing oil in this embodiment are shown in Table 5.

[0060] Parts by weight of each component of glazing oil in Table 5 Example 3

[0061] components

parts by weight

Ethyl Acrylate Modified Waterborne Polyurethane Emulsion

450

Acrylic resin liquid S-2919

400

BASF Wax Emulsion

60

Tego 810 defoamer

15

[0062] Digo Glide100 leveling agent

60

Tego 245 wetting agent

15

Alcohol ester twelve film-forming aids

10

Deionized water

120

[0063] The preparation steps are as follows:

[0064] (1) Proportionally disperse the water-based polyurethane emulsion modified by ethyl acrylate and deionized water with a homogenizer for 20 minutes, and the homogenizer speed is 750r / min;

[0065] (2) Add the acrylic resin liquid to the mixture obtained in step (1), continue to disperse for 30 minutes with a homogenizer, and the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com