Construction method of checker brick block for hot blast stove based on bim technology

A construction method and lattice brick technology, applied in the field of construction and industrial furnace construction, can solve the problems of increased repair cycle, loose and unstable lattice bricks, etc., and achieve the effect of reducing through-hole errors, saving engineering costs, and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

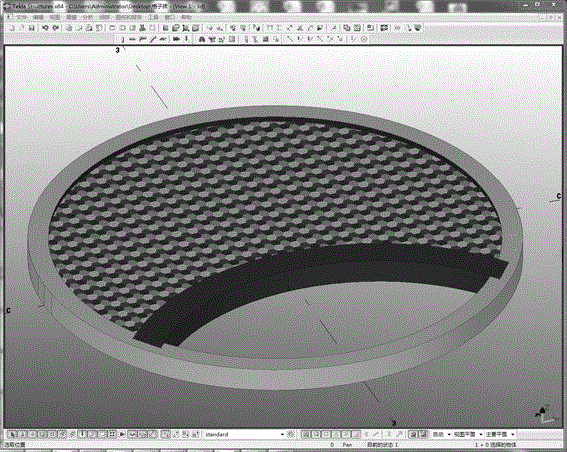

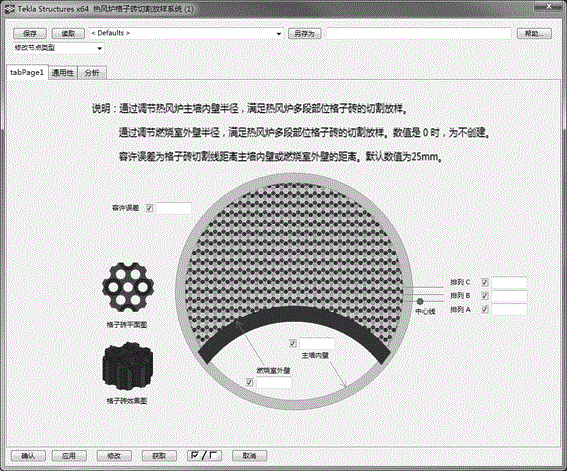

[0049] Such as figure 1 , figure 2 , image 3 ( figure 2 belong image 3 As shown in the shortcut key), the specific steps of the construction method of the hot blast stove checker brick block based on BIM technology provided by the present invention are as follows:

[0050] 1. First create a single lattice brick section according to the drawing, and array the inner space of the inner wall of the main wall of the hot blast stove;

[0051] 2. Create the main wall pipe of the hot blast stove and the round pipe of the combustion chamber wall, and set cutting at the junction of the round pipe of the combustion chamber wall and the main wall pipe of the hot blast stove;

[0052] 3. Use the tool "Cut Parts Using Another Part" to cut the cross-section of the checker brick that is in contact with the main wall tube of the hot blast stove and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com