Strip steel pickling circulating system

A circulation system and strip steel technology, applied in the field of pickling, can solve the problems that the quality of strip steel pickling cannot be well controlled, increase the frequency of acid liquid waste acid discharge, increase the consumption of new acid, etc., and achieve the reduction of waste acid The effect of discharging frequency, improving the surface quality of pickling, and saving acid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

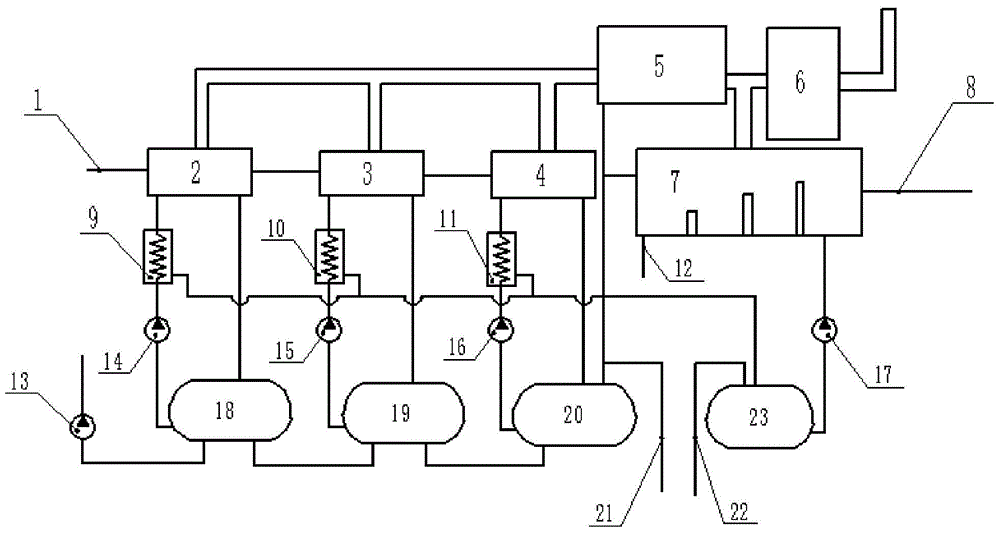

[0014] Examples, see attached figure 1 , including strip steel inlet 1, first pickling tank 2, second pickling tank 3, third pickling tank 4, acid mist pretreatment device 5, acid mist purification tower 6, rinse tank 7, strip steel outlet 8, First heater 9, second heater 10, third heater 11, rinse water discharge port 12, waste acid discharge pump 13, first circulation pump 14, second circulation pump 15, third circulation pump 16, water pump 17 , the first acid storage tank 18, the second acid storage tank 19, the third acid storage tank 20, the fresh acid pipe 21, the water supply pipe 22 and the condensed water tank 23, it is characterized in that, the first pickling tank 2 is provided with There is a strip steel inlet 1, the first pickling tank 2 is connected with the second pickling tank 3, the second pickling tank 3 is connected with the third pickling tank 4, the first pickling tank 2, the second pickling tank The second pickling tank 3 and the third pickling tank 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com