Construction method of permanent retaining system characterized by joint work of basement floor slabs and retaining piles

A permanent support and construction method technology, applied in excavation, infrastructure engineering, construction, etc., can solve problems such as disconnection, waste of building materials and social resources, and achieve the effects of reducing horizontal stress, improving force characteristics, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

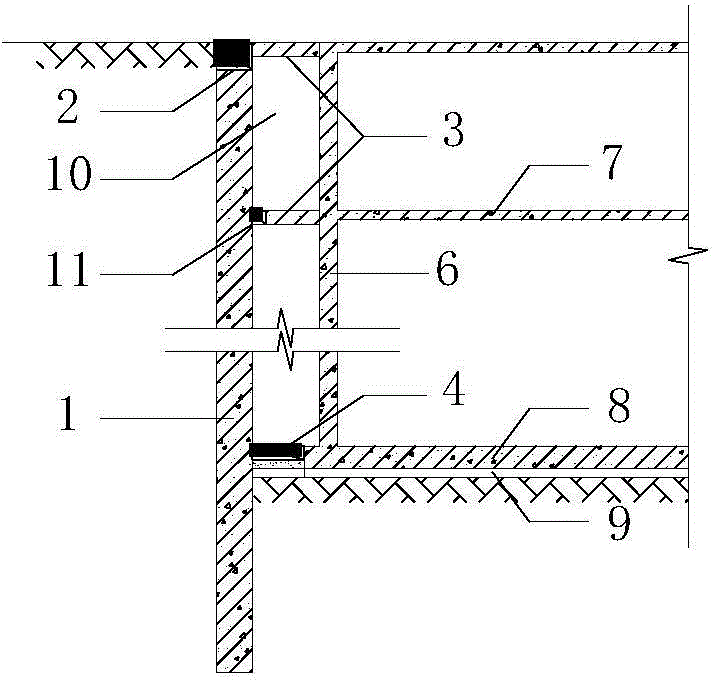

[0043] figure 1 As shown, during the excavation of the foundation pit and the construction of the underground structure, the foundation pit support adopts the pile-anchor support system.

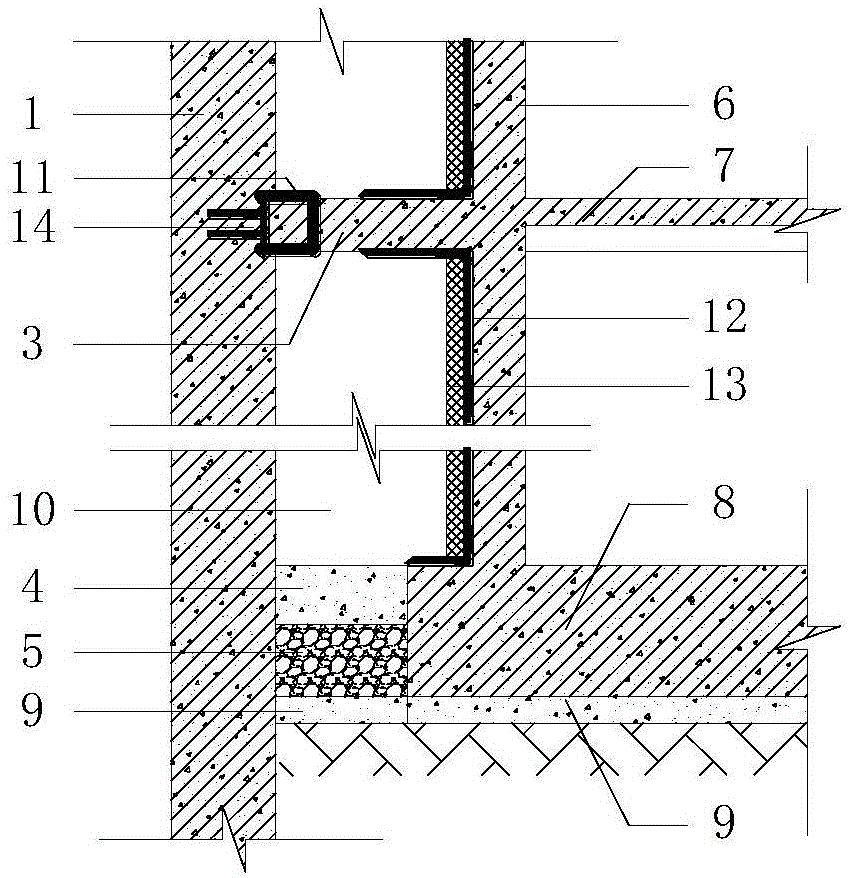

[0044] figure 2 As shown, the first permanent outrigger is the outrigger 4 of the foundation raft, which is located in the plane of the foundation raft 8 and is supported by plain concrete.

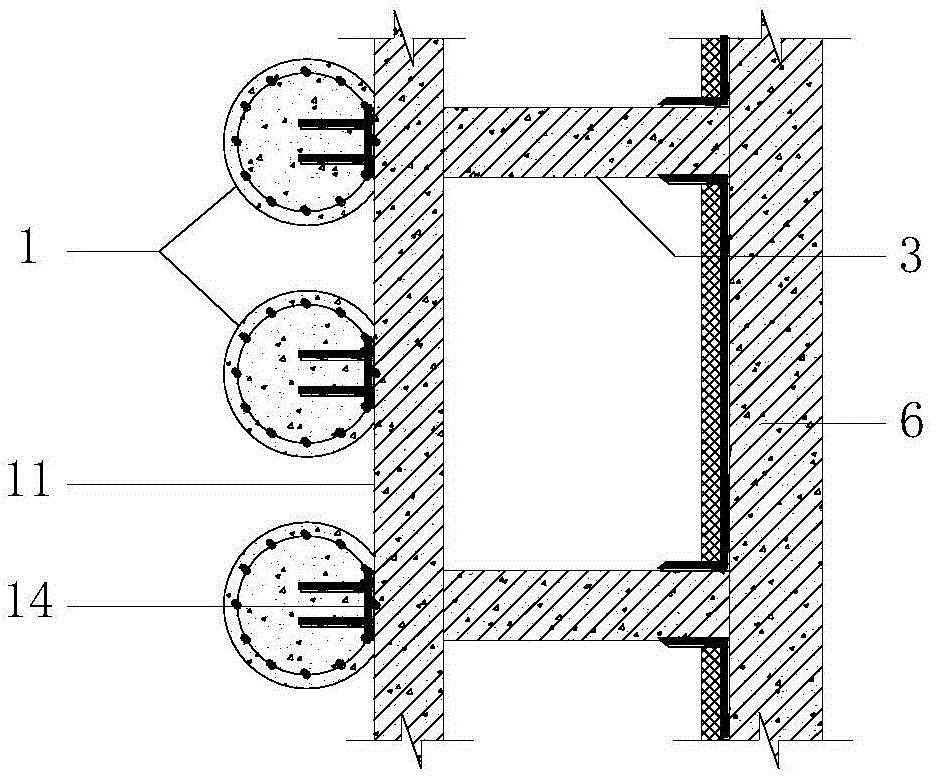

[0045] The supporting system includes concrete bored piles 1, crown beams 2, main structure outriggers 3, foundation raft outriggers 4, gravel sand layer 5, basement exterior wall 6, basement floor slab 7, and foundation raft slab 8 , base cushion 9, backfill soil 10, waist beam 11, basement exterior wall waterproof layer 12, basement exterior wall insulation layer 13, and embedded parts 14.

[0046] figure 2 As shown, the supports other than the first outrigger are located in the floor plane of the corresponding height. They are the outrigger supports of the main structure and belong to reinforced...

Embodiment 2

[0058] The construction process of the permanent support system in which the basement floor slab and support piles work together includes the following steps:

[0059] (1) perform bored pile 1;

[0060] (2) Excavation of foundation pit and installation of bolts;

[0061] (3) Apply foundation cushion 9 and foundation raft 8;

[0062] (4) A permanent plain concrete support is set between the foundation raft 8 and the support pile 1, that is, the outreach support 4 of the foundation raft. For the construction waste in the empty slots between the guard piles, lay a 200mm thick plain concrete cushion, backfill the sand layer 5 with well-graded crushed stones, and pour plain concrete horizontal support not less than 500mm thick in the plane of the raft, the first layer The outrigger construction is completed;

[0063] (5) The first anchor cable is dismantled and recovered: after the foundation raft outrigger 4 reaches 80% of the design strength, remove and recover the first ancho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com