Automatic control system alternatively filled with simulated polymer solution

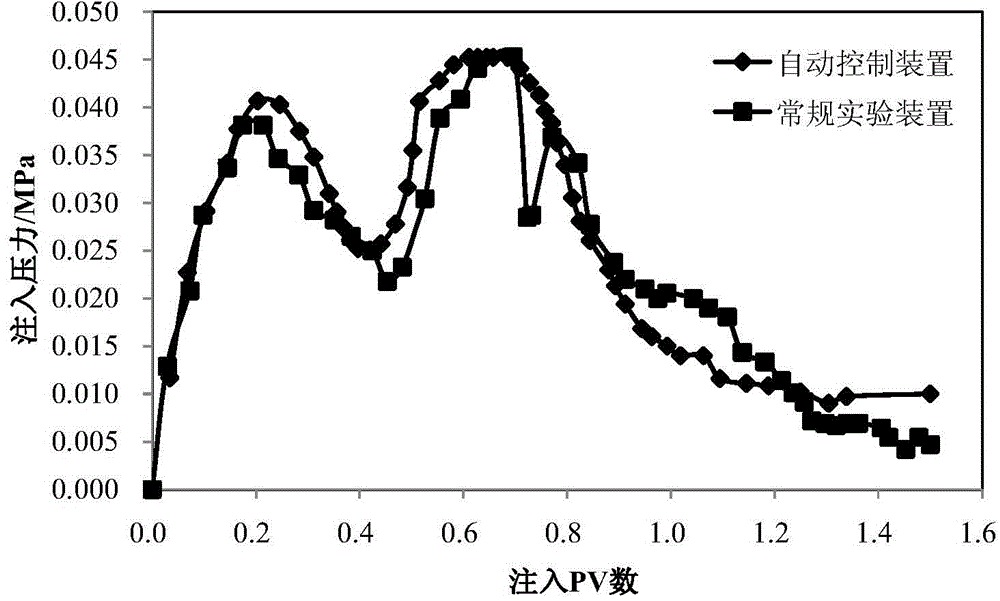

An automatic control system and polymer solution technology, applied in the field of oilfield chemical flooding, can solve problems such as large errors and data fluctuations, and achieve the effects of avoiding pressure fluctuations, reducing experimental errors, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

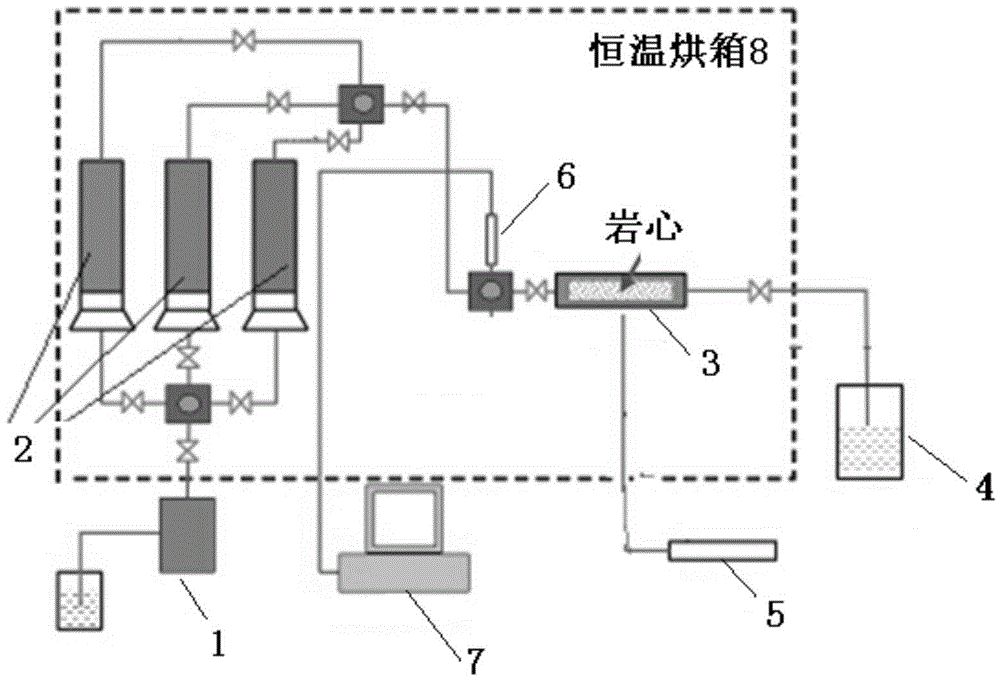

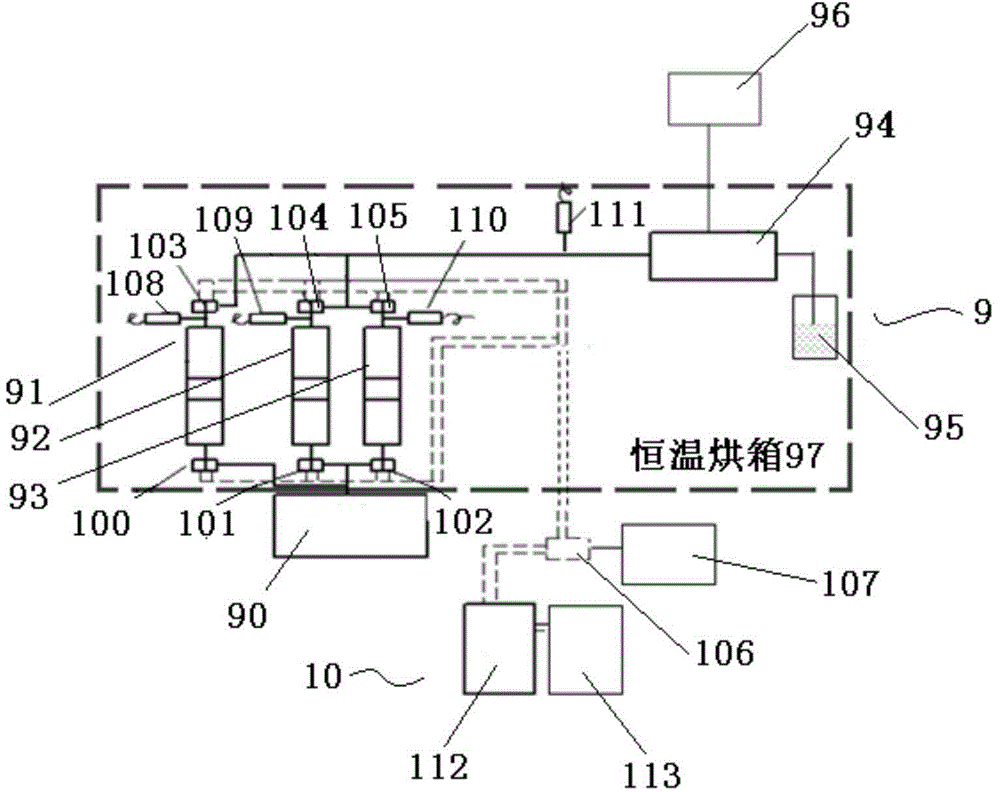

[0016] Such as figure 2 As shown, the present invention includes a polymer alternate injection experimental device 9 and an automatic switching control device 10 . Among them, the polymer alternate injection experimental device 9 is basically the same structure as the commonly used polymer alternate injection experimental device, including an advection pump 90, a first intermediate container 91, a second intermediate container 92, a third intermediate container 93, a core holder 94, Liquid collection container 95, confining pressure pump 96 and constant temperature oven 97. The automatic switching control device 10 includes high-pressure pneumatic valves 100 - 105 , a solenoid valve group 106 , an air compressor 107 , pressure sensors 108 - 111 , a control box 112 and a computer 113 .

[0017] The output end of the horizontal flow pump 90 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com