A roadway surrounding rock control method based on drilling pressure relief and grouting strengthening

A technology of drilling pressure relief and surrounding rock control, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as inability to coordinate, save costs and procedures, promote the stability of roadway surrounding rock, and facilitate surrounding rock grouting strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0027] The invention provides a roadway surrounding rock control technology in which drilling pressure relief and grouting strengthening are coordinated.

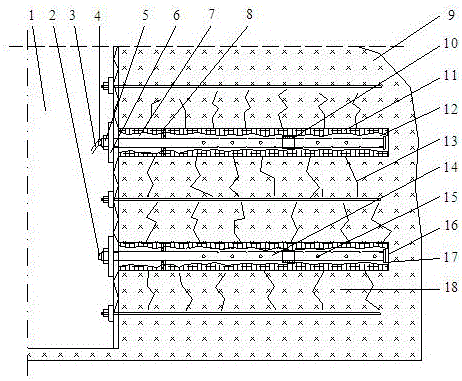

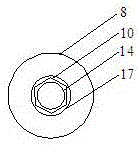

[0028] Such as Figure 1~3 Shown, the specific embodiment of the present invention comprises the following steps:

[0029] Step 1, in the large-deformation anchoring roadway 1 supported by the anchor net, the basic parameters such as the position, quantity, aperture and depth of the pressure relief drilling 16 are determined according to the deformation of the surrounding rock;

[0030] Step 2, using a drilling rig to drill holes at designated locations, the pressure relief drilling holes 16 are perpendicular to the wall surface, and the depth reaches the elastic zone 9;

[0031] Step 3, after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com