Slot aerodynamic journal bearing

A radial bearing and groove technology, applied in the field of gas bearings, can solve the problems of low critical speed of bearings, insufficient bearing rigidity, easy instability, etc., and achieve the effect of high limit speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

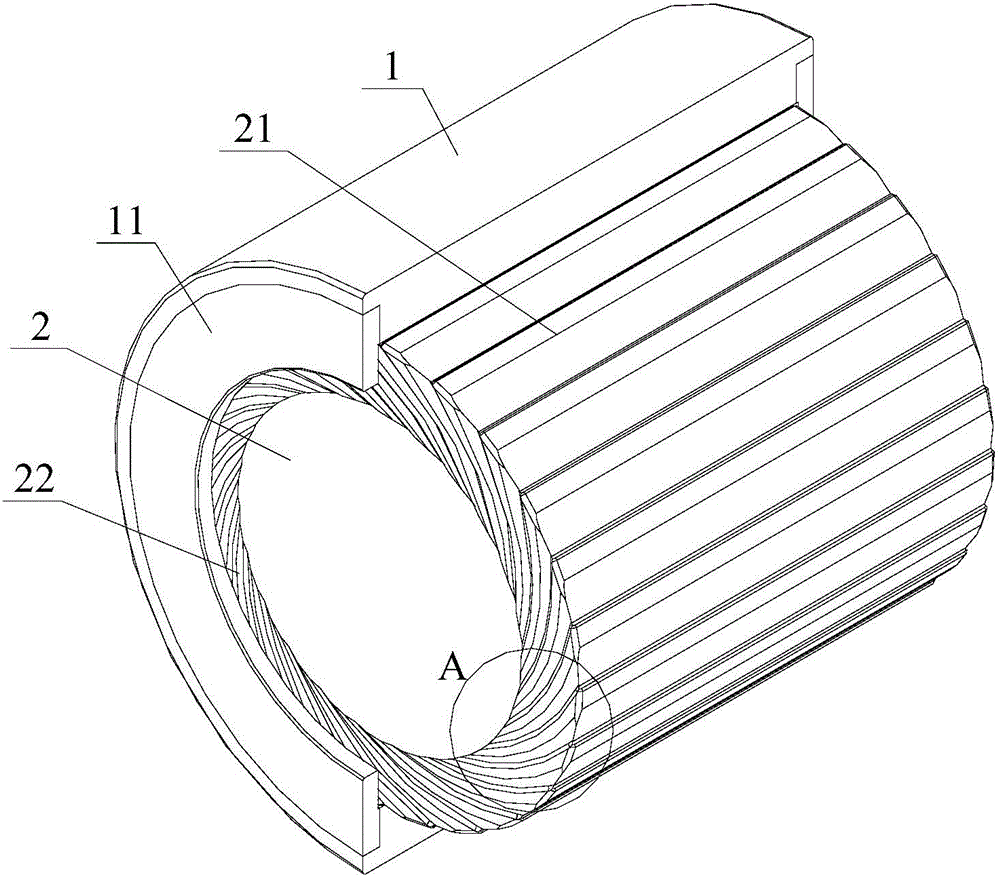

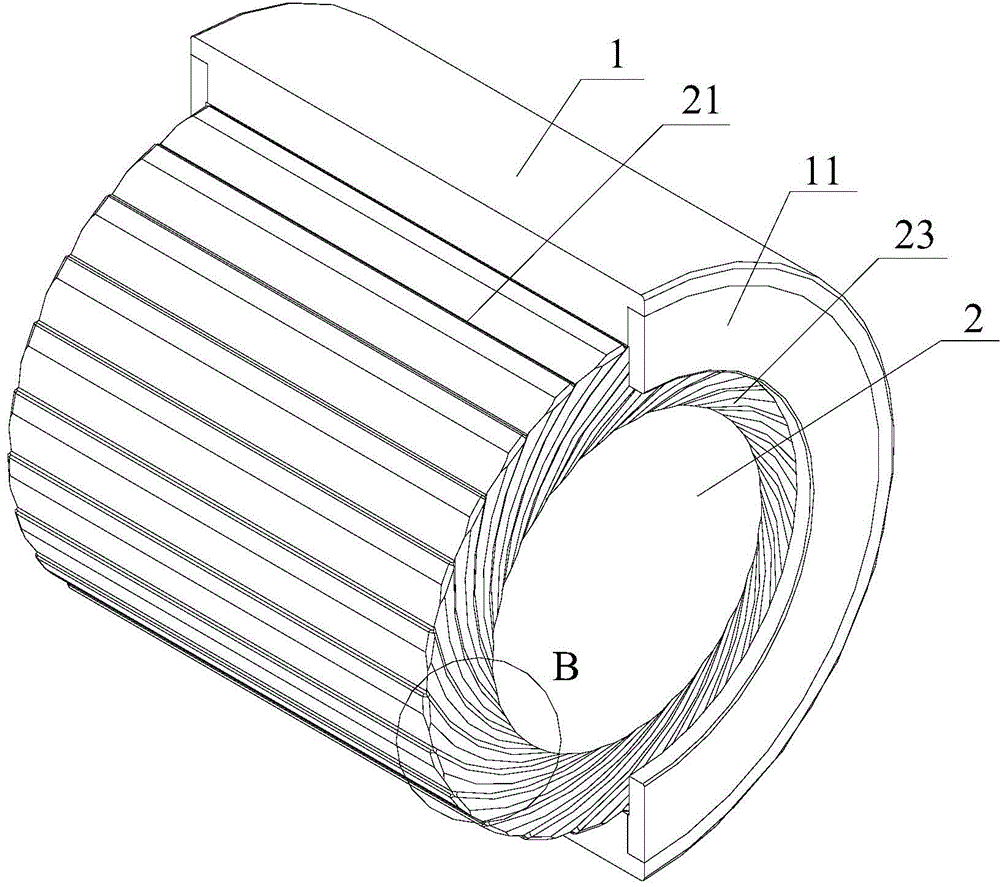

[0027] Such as figure 1 and image 3 As shown: a groove type dynamic pressure gas radial bearing provided in this embodiment, comprising: a bearing outer sleeve 1 and a bearing inner sleeve 2, the outer circumferential surface and the left and right end surfaces of the bearing inner sleeve 2 have regular shapes Groove patterns (21, 22 and 23 in the figure, the groove patterns in this embodiment are all in the shape of impellers), and the groove pattern 22 on the left end surface and the groove pattern 23 on the right end surface form a mirror image.

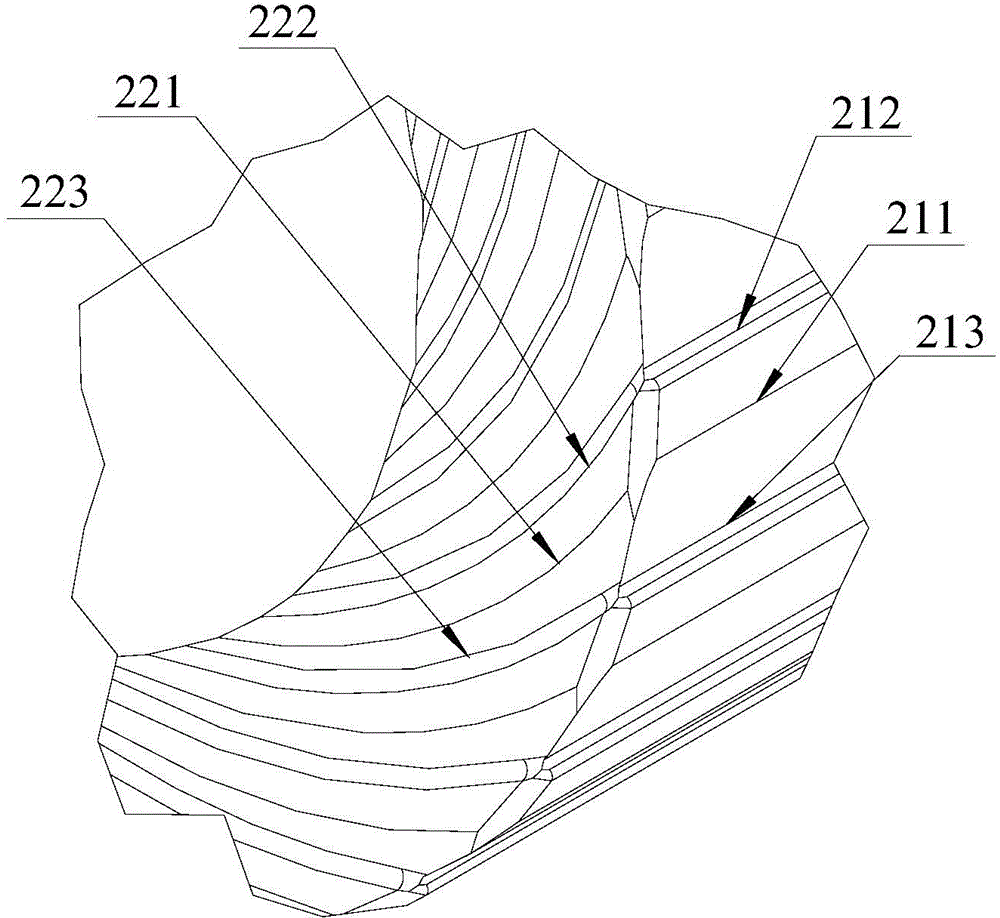

[0028] combine Figure 1 to Figure 4 As shown: the axial contour lines of the groove patterns 21 on the outer circumferential surface of the bearing inner sleeve 2 and the radial contour lines of the groove patterns (22 and 23) on the left and right end faces form a one-to-one correspondence and intersect each other , that is: the axial high position line 211 in the groove pattern 21 on the outer circumferential surface corresp...

Embodiment 2

[0032] Such as Figure 5 and Figure 6 As shown, the difference between the groove type dynamic pressure gas radial bearing provided in this embodiment and that of Embodiment 1 is that there are coaxial through holes 12 and concave holes 13 on the outer circumference of the bearing housing 1, so The above-mentioned through hole 12 is located in the coaxial concave hole 13 . The through hole 12 and the recessed hole 13 are provided to facilitate the installation and data collection of sensors (such as temperature sensors, pressure sensors, rotational speed sensors, etc.) used to monitor the running state of the bearing online.

[0033]After testing: the groove-type dynamic pressure gas radial bearing provided by the present invention can realize a load capacity of 1-3kg and a limit speed of 200,000-450,000rpm, while the existing groove-type dynamic pressure gas radial bearing can only achieve a load capacity of 0.5-1.5 kg load capacity and 100,000-200,000rpm limit speed; it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com