A trans-critical CO2 heat pump water heater pressure control method and system

A heat pump water heater and control method technology, applied in refrigerators, refrigeration components, fluid heaters, etc., can solve problems such as complex processes, and achieve the effect of more, faster and more direct adjustment methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

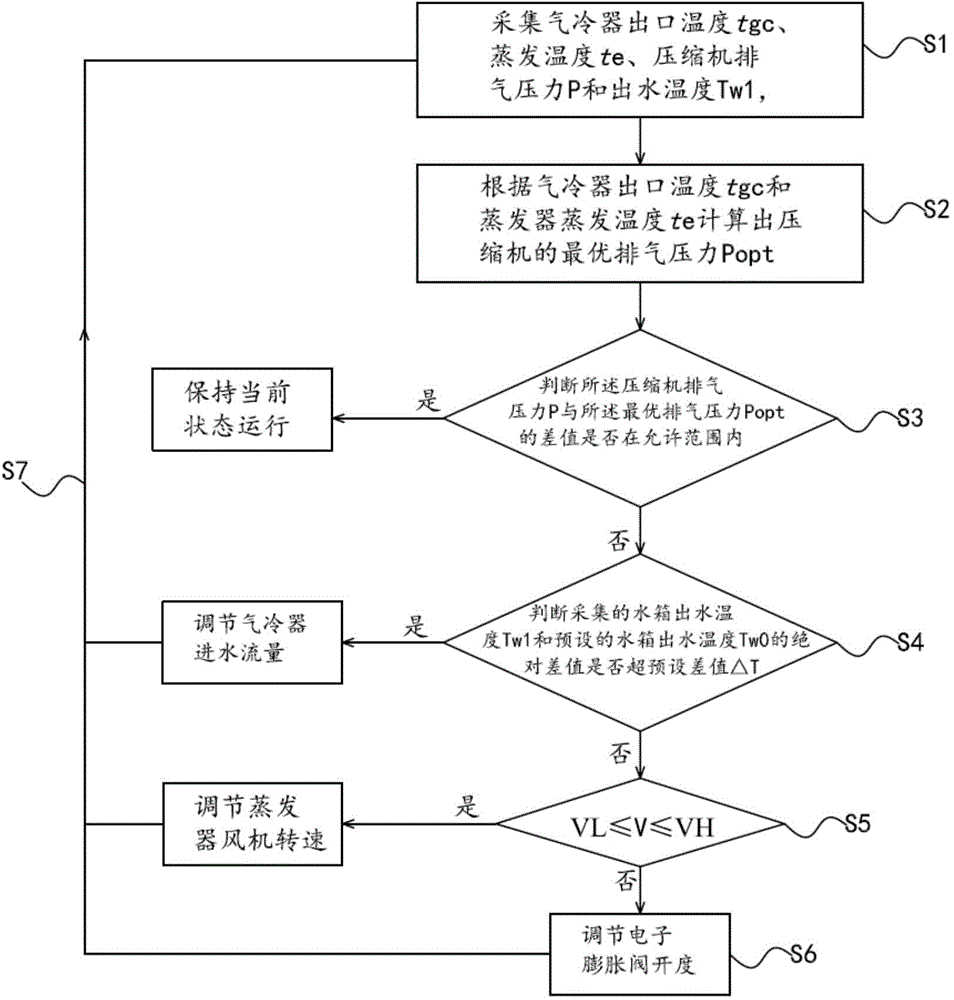

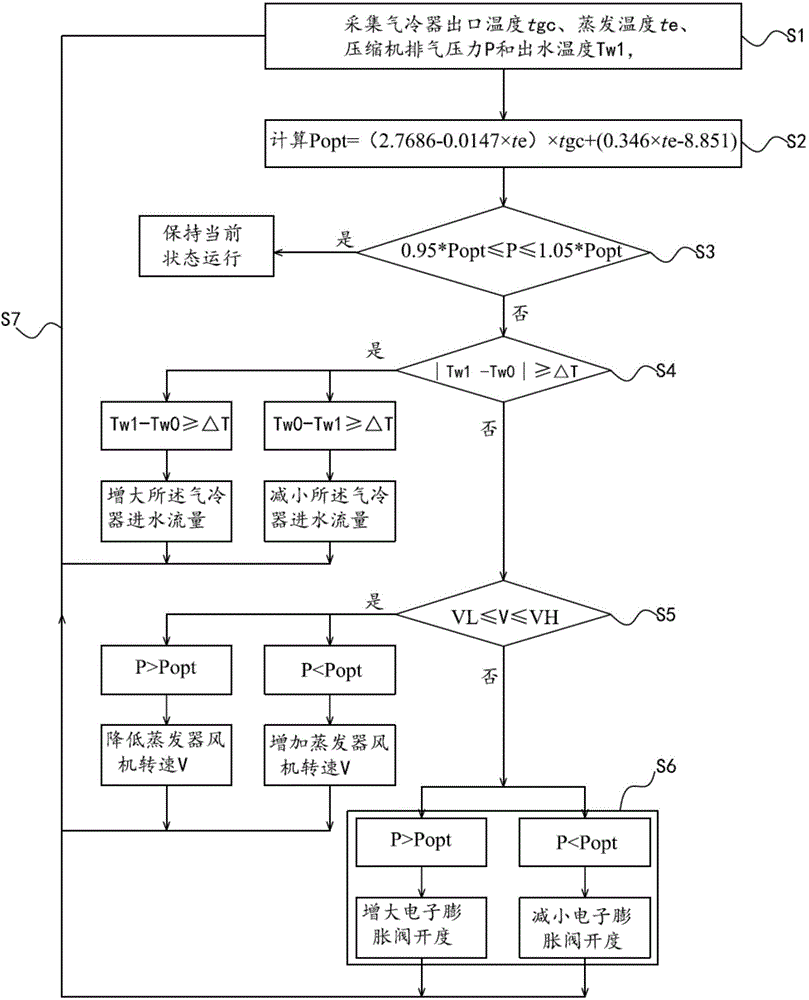

[0052] Transcritical CO of the present invention 2 For the flow control diagram of Embodiment 1 of the pressure control method of the heat pump water heater, see figure 1 , including the following steps.

[0053] Step S1, collect the outlet temperature t of the air cooler of the water heater system gc , evaporator evaporation temperature t e , compressor exhaust pressure P and water tank outlet temperature T w1 .

[0054] Step S2, according to the outlet temperature t of the air cooler gc and evaporator evaporation temperature t e Calculate the optimal discharge pressure P of the compressor opt .

[0055] Step S3, judging the compressor discharge pressure P and the optimal discharge pressure P opt Whether the difference is within the allowable range, if yes, keep the current running state; otherwise, go to step S4.

[0056] Step S4, judging th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com