Automobile paint thickness measuring apparatus and method

A technology for thickness measurement and automotive paint, applied in the direction of electromagnetic measuring devices, electric/magnetic thickness measurement, etc., can solve the problems of narrow frequency band, heavy weight, and many varieties and specifications, and achieve long service life, novel structure, and unique design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

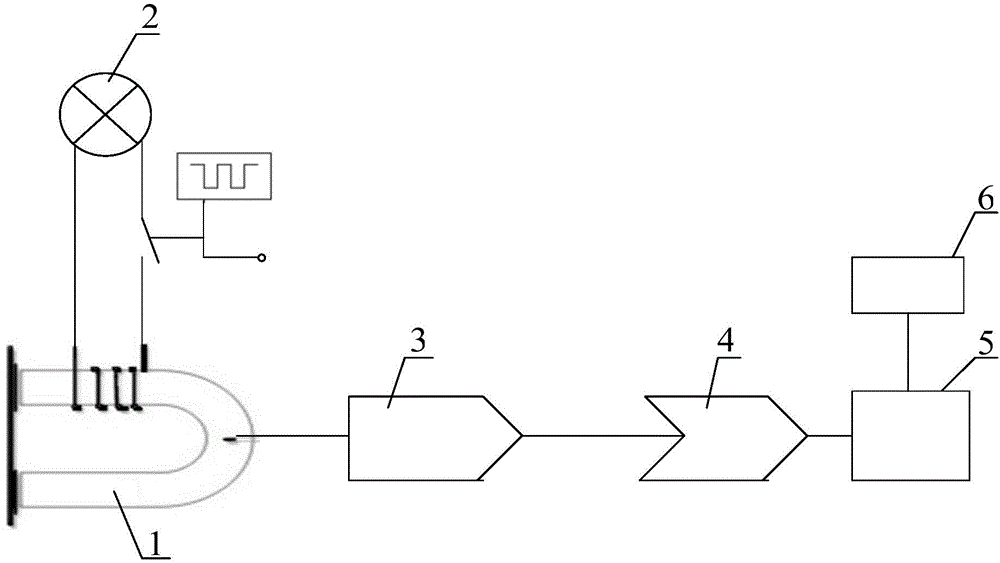

[0045] Such as figure 1 As shown, the automotive paint thickness measuring device includes a U-shaped iron core 1, a phase-locked amplifier circuit 3 and an A / D conversion module 4. A tunnel junction magnetic sensor is embedded in the U-shaped iron core 1, and the tunnel junction magnetic sensor is the sensing area Nano-type tunnel junction magnetic sensor smaller than 1 square micron, magnetic field sensitivity 50mV / V.Oe, magnetic field noise 1 nanometer level, operating temperature above 400°C, wide frequency response 10GHZ, and several turns of excitation coils, connected to constant current Source 2, constant current source 2 is a constant current source that outputs a 1KHz square wave constant current signal, the output end of the tunnel junction magnetic sensor is connected to the lock-in amplifier circuit 3, and the lock-in amplifier circuit 3 is connected to the A / D conversion module 4, and the A / D conversion module 4 is connected to send into single-chip microcomputer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com