Water level measuring system for boiler drum and measuring and checking method thereof

A technology of water level measurement and boiler steam drum, applied in the direction of displaying liquid level indicator through pressure measurement, etc., can solve problems such as changing the relationship between water level and differential pressure thermodynamics, overflow of differential pressure range, and inconsistent readings after adjustment. Standardization of device data, less heat loss, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

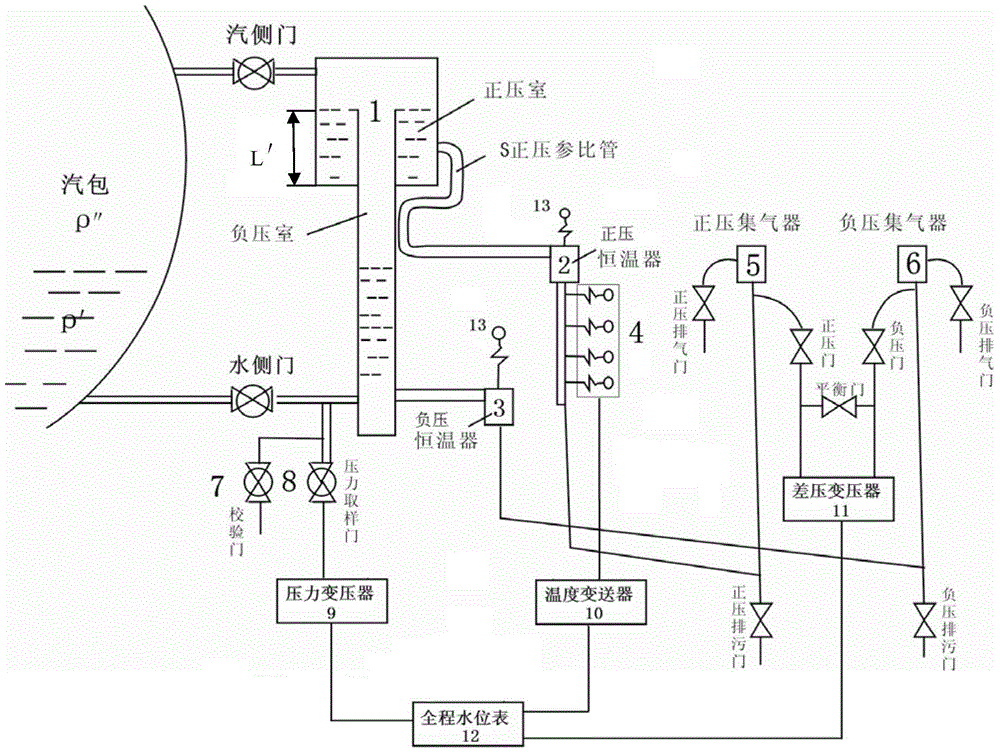

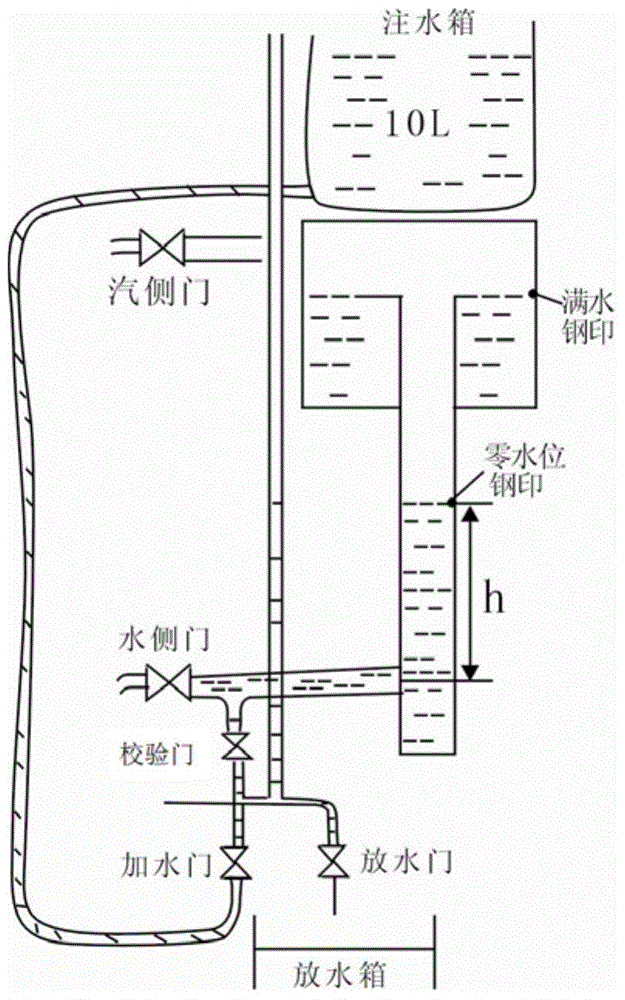

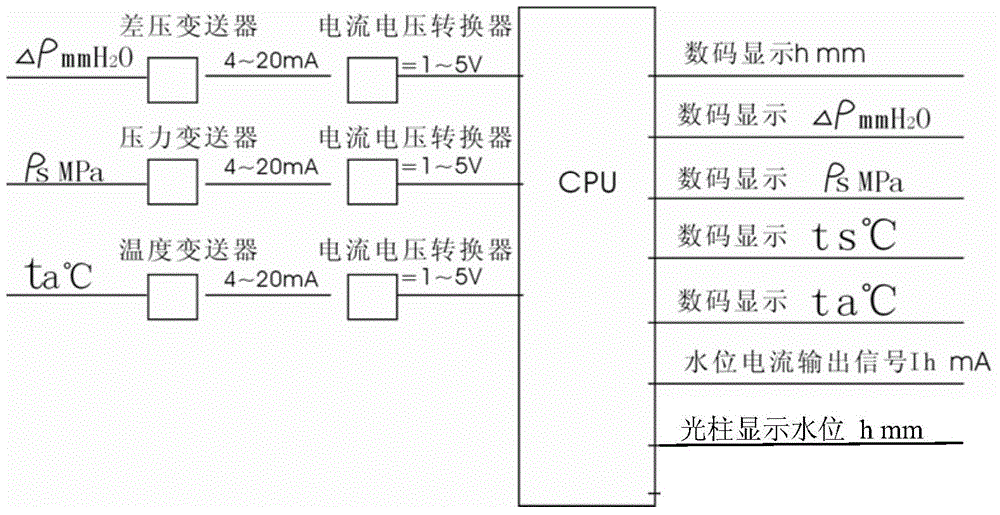

[0049] The present invention has tested this steam drum water level measuring system on the 220t / h high pressure furnace and 670t / h super high pressure furnace. The working environment temperature is 5-90 degrees. The water level measuring system comprises a water level measuring device 1, a thermostat, an average density measuring device 4, a pressure sampling door 8, a pressure transmitter 9, a temperature transmitter 10, a differential pressure transmitter 11 and a full-range water level gauge 12; the water level The measuring device 1 is connected with the steam side door and the water side door of the boiler drum, connected with the differential pressure transmitter 11 through the thermostat, and connected with the pressure transmitter 9 through the pressure sampling door 8; the thermostat is connected with the average density measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com