Multifunctional inverted conical sterilization equipment and sterilization process

An inverted cone-shaped, multi-functional technology, applied in heating, chemistry, etc., can solve the problems of secondary polluting materials, affecting the quality and safety of traditional Chinese medicine preparations, and high cost, and achieve the effect of wide range of temperature adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The following examples are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

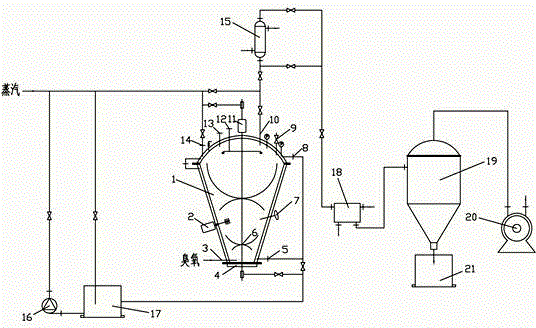

[0021] refer to figure 1 , a multi-functional inverted cone sterilization equipment of the present invention, which includes a vertical sterilization cylinder, a tube condenser 15, a circulation pump 16, a sump A17, a plate condenser 18, a buffer tank 19, a vacuum pump 20 and a collection Water tank B21, the air outlet 10 of the vertical sterilization cylinder 1 is connected to the tube condenser 15, the tube condenser 15 is connected to the plate condenser 18, the plate condenser 18 is connected to the buffer tank 19, and a water collection tank is placed at the bottom of the buffer tank 19 B21, the buffer tank 19 is connected to the vacuum pump 20, the drain port 8 of the barrel cover, the dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com