Double-headed bolt assembling and disassembling tool

A technology for disassembling tools and stud bolts, applied in the field of auxiliary equipment for stud bolt installation and disassembly, can solve the problems of high labor intensity, unsatisfactory seismic and buffer performance, loss of fastening force, etc., and achieve the effect of expanding the scope of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

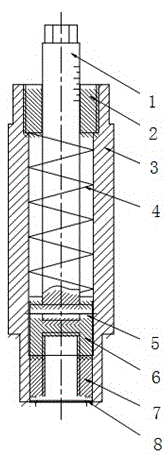

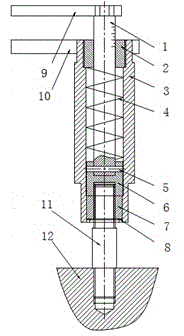

[0022] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

[0023] The invention provides a stud bolt installation and removal tool, which is convenient and reliable in assembly. Simple structure, flexible disassembly, easy use, low manufacturing cost, can greatly reduce labor intensity, suitable for operations in small and special spaces, can quickly replace parts, and can be used for stud bolts of different diameters.

[0024] As an embodiment of the present invention, the present invention provides a stud bolt installation and removal tool, including a locking rod 1, a nut 2, a chamfered outer sleeve 3, a spring 4, a cylindrical pin 5, a pre-tightening nut 6, and a flange clamp Tightening nut 7, retaining ring 8 for hole, first wrench 9 and second wrench 10, described locking rod 1 is inserted in the overcoat 3 of chamfering, and described locking rod 1 tail end is fixed with first wrench 9, The locking rod 1 is covered with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com