Prefabricated special-shaped light-steel composite wall board and mounting method thereof

A composite wallboard and prefabricated technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of modular design, production and installation of the overall wallboard, the degree of assembly stays at the component level, and the cost of the wallboard is high. , to achieve high bearing capacity, reduce the overall cost and save the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

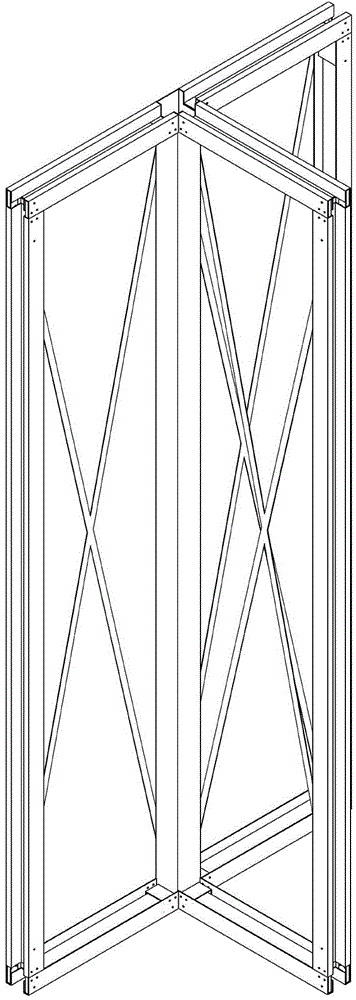

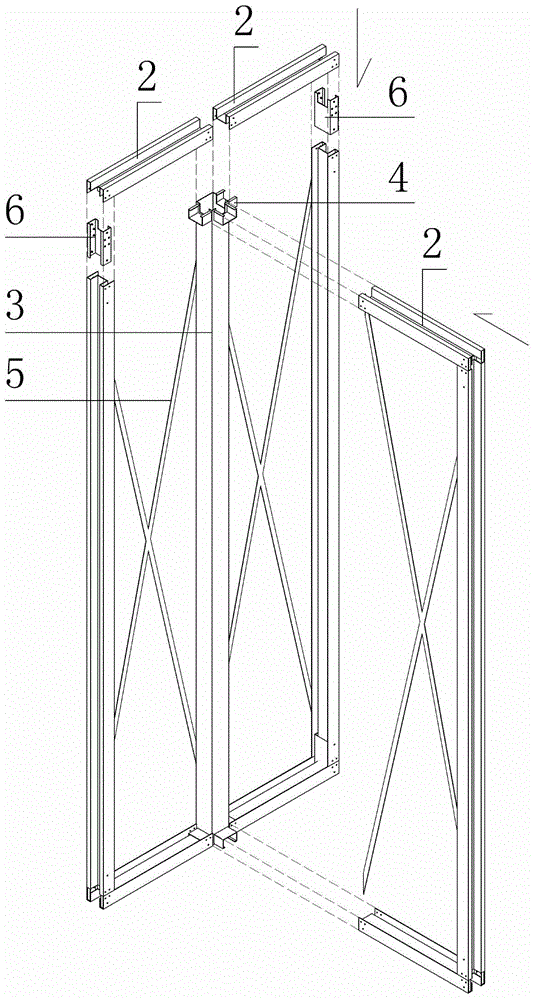

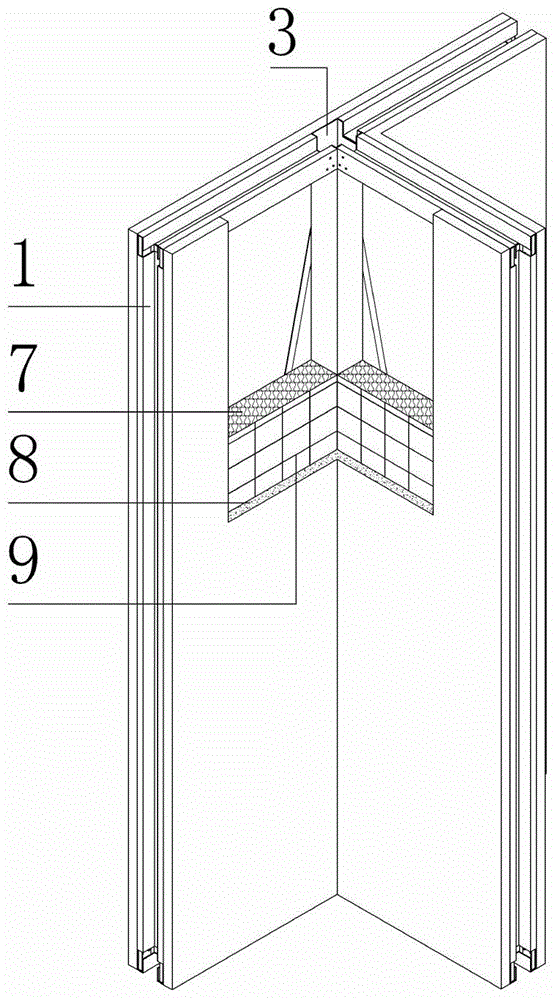

[0026] Such as Figure 1-5 Shown, a kind of prefabricated special-shaped light steel composite wallboard and installation method thereof, during concrete implementation, at first according to the size blanking of the prefabricated special-shaped light steel composite wallboard of actual needs, make frame M-shaped steel 2, corner square steel 3 (comprising bearing Plug 4), diagonal brace 5, U-shaped connector 6, the above-mentioned various components are attached figure 1 , 2 The form is connected with self-tapping screws in the factory to form a light steel frame 1;

[0027] Lay steel mesh 9 on one side of the light steel frame 1 processed above, and weld and fix it with the light steel frame 1, then put the steel mesh 9 face down together with the light steel frame 1 into a special formwork, and place it on the bottom surface of the formwork. Set a 15mm high pad, pour self-compacting cement slurry according to a certain proportion into the light steel frame 1, and level it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com