Underwater high-precision measurement and control system and method for pipe abutment in the construction of immersed tunnel

An immersed tube tunnel, measurement and control system technology, applied to radio wave measurement systems, measurement devices, measuring instruments, etc., to achieve the effect of improved accuracy and reliability, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

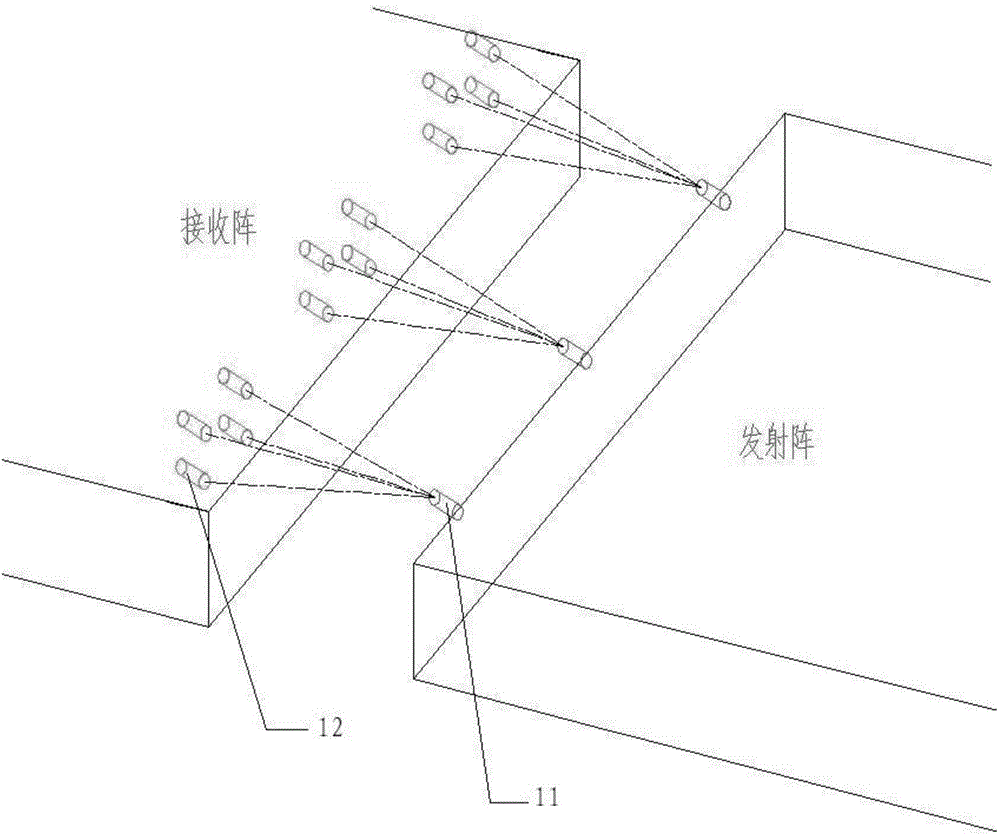

[0046] see figure 1 , an underwater high-precision measurement and control system for the docking of pipe sections in the construction of immersed tunnels, with multiple groups of receiving / transmitting ultrasonic sensors, an industrial PC control platform, a serial / wireless network communication system, a command room PC control and display platform, and multiple groups of receiving / transmitting ultrasonic sensors. / The transmitting ultrasonic sensor is connected with the industrial PC control platform through coaxial cable, and the industrial PC control platform is connected with the command room PC control and display platform through the serial port / wireless network communication system. The ultrasonic sensor is connected and controlled by the industrial PC control platform through the coaxial cable, and the control and data transmission between them adopts the bus mode.

[0047] There are three groups of receiving / transmitting ultrasonic sensors. In each group of receivi...

Embodiment 2

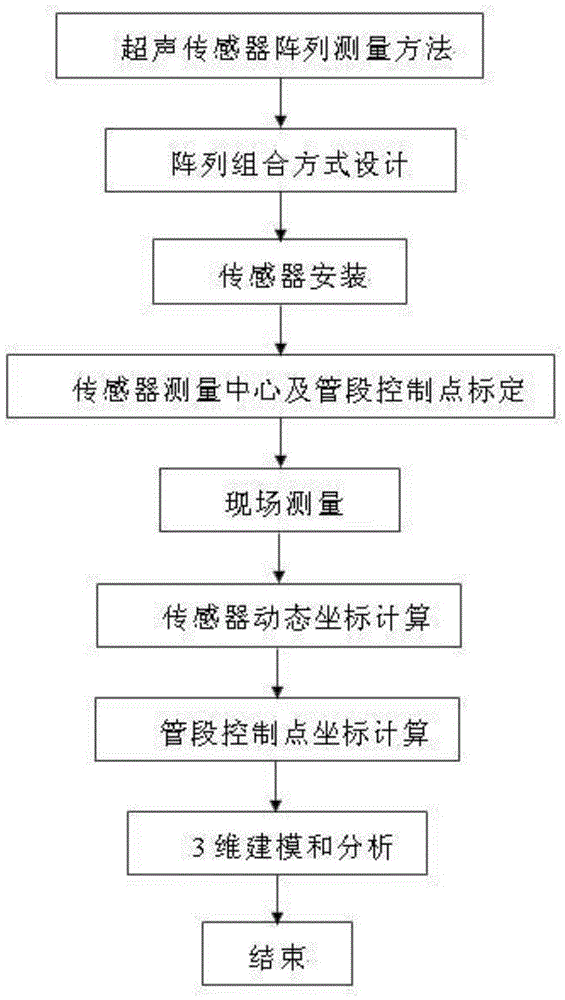

[0060] see figure 1 and figure 2 , a measurement and control method realized by applying the underwater high-precision measurement and control system for the docking of pipe sections in the construction of the immersed tube tunnel in the first embodiment, comprising the following steps:

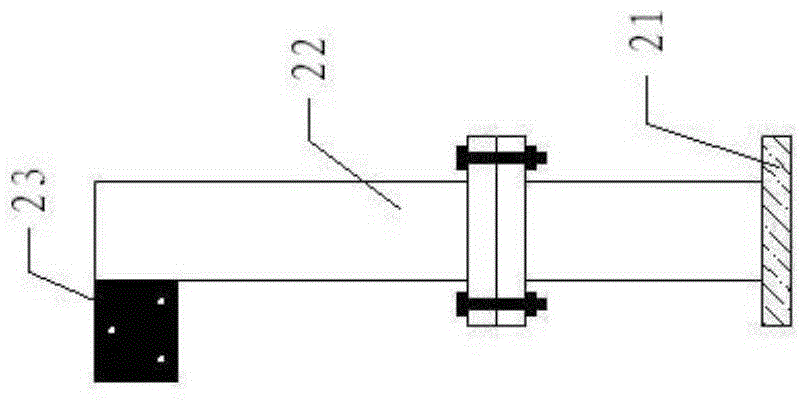

[0061] S1. Install sensors, receive / transmit ultrasonic sensors in groups and install them face-to-face at the tube head and tube tail;

[0062] S2. The measurement center and preset control point of the receiving / transmitting ultrasonic sensor are calibrated. The high-precision total station is used to measure the spatial coordinate values of the sensor center, the preset control point and the corner point of the pipe section in the same coordinate system, which is used for the relative attitude of the pipe section. calculation;

[0063] S3. On-site measurement, control the sound wave transmission and reception of the receiving / transmitting ultrasonic sensor, and calculate the spatial d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com