High-airtightness sample preparation device and sample preparation method thereof

A high sealing and sealing ring technology, applied in the preparation of test samples, etc., can solve the problems of large influence on sample uniformity and insufficient air tightness, so as to achieve relative density and uniformity of samples and low cost , easy to precisely control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

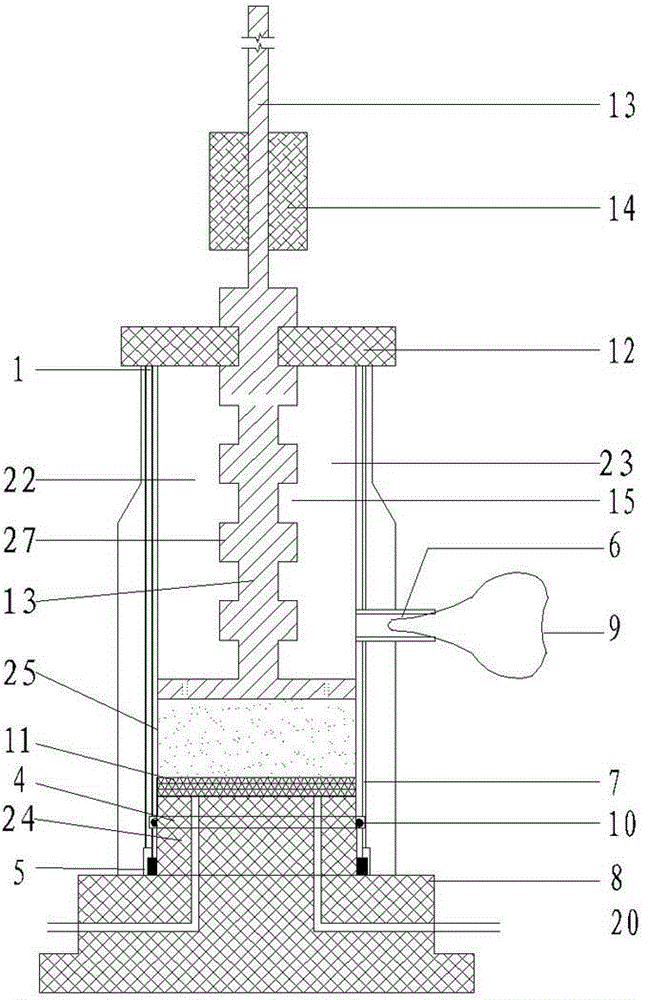

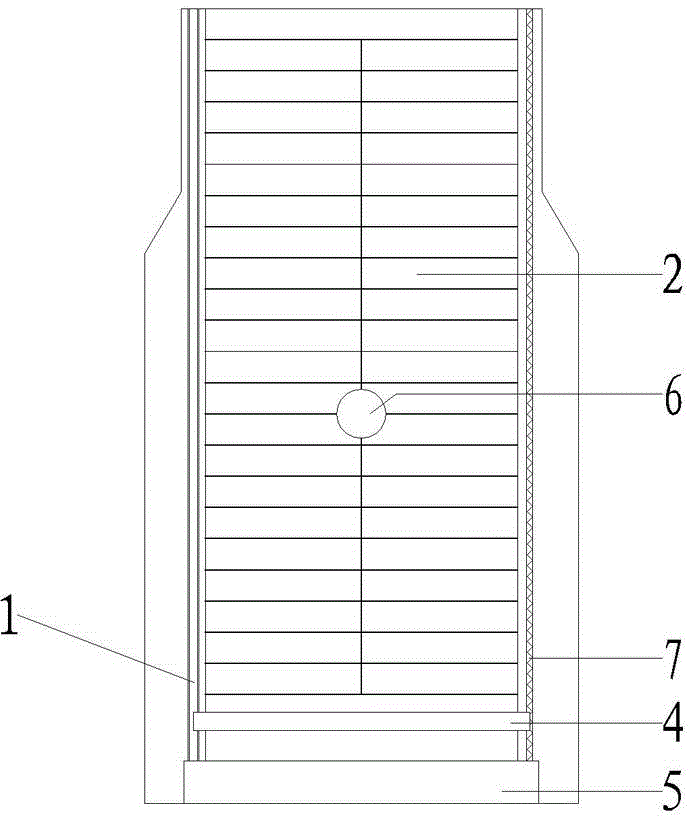

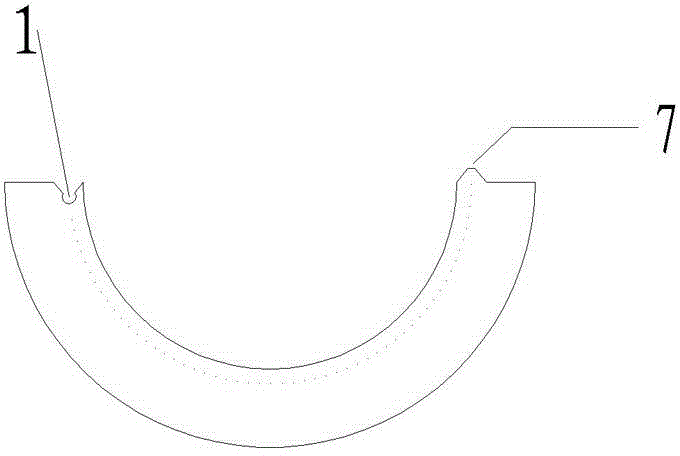

[0032] refer to Figure 1-Figure 9As shown, the high-seal sample preparation device provided by the present invention includes a base 8, a multi-lobed arc-shaped tile mold 22, a top cap 21, a compaction guide rod 13 and a retainer 12, and the arc-shaped tile mold 22 has a There are vertical slots 1 and vertical protrusions 7 matching the vertical slots 1 on both sides, rubber gaskets are embedded in the vertical slots 1, and the adjacent arc-shaped tile molds 22 are vertically convex after docking. The lifting 7 is inserted into the vertical slot 1 to form an airtight seal. The multi-lobed arc-shaped tile mold 22 is docked and surrounded to form a cylinder 23. The cylinder 23 is sleeved on the boss 24 of the base 8. The top cap 21 is set on the top of the cylinder 23, the inner side of the cylinder 23 is lined with a rubber film 25, the upper end of the rubber film 25 is folded outwards and put on the outer wall of the cylinder 23, the butt joint of the curved tile mold 22 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com