Biological filter paper and its preparation method and application

A biological filtration and formulation technology, applied in the field of filter paper, can solve the problems of not being suitable for biopharmaceutical filtration, easy to fall off of its own particles, and difficult to clean, and achieve the effects of being conducive to popularization and use, low resistance, and easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

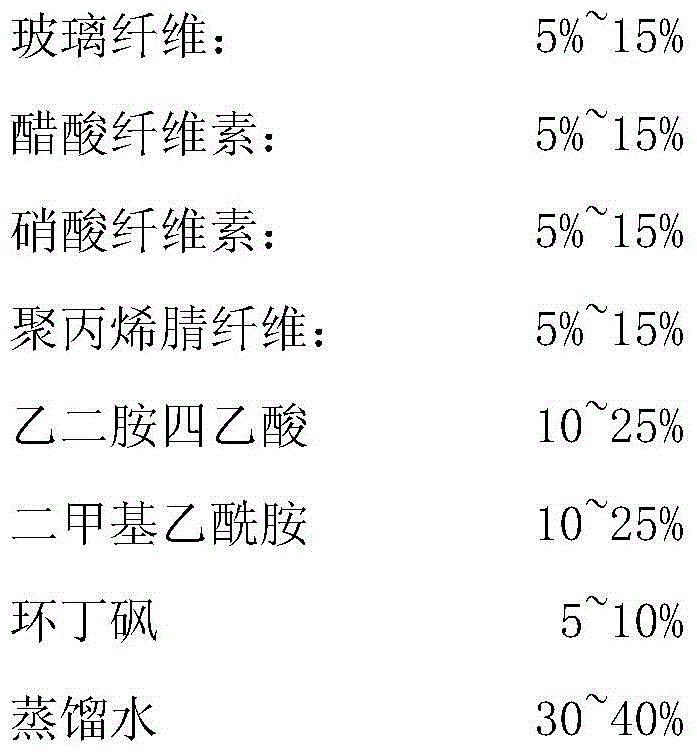

[0026] A biological filter paper prepared from the following components:

[0027]

[0028] The acetyl group content in the cellulose acetate is 40% to 42%;

[0029] The acrylonitrile content in the polyacrylonitrile fiber is greater than 92%;

[0030] The quantification of described biological filter paper is 320g / m 2 , thickness 0.60mm, water absorption 900g / m 2 .

[0031] Its preparation method comprises the following steps:

[0032] (1) Soak the glass fiber with 8% HCl at room temperature, and wash with water until there is no to no Cl atom;

[0033] (2) preparing a solution, stirring the ethylenediaminetetraacetic acid, dimethylacetamide and distilled water of the formula quantity to obtain a mixed solution;

[0034] (3) Glass fiber, cellulose acetate, nitrocellulose, and polyacrylonitrile fiber of formula quantity are dissolved in the mixed solution of step (2), fully stirred to obtain pasty substance;

[0035] (4) add sulfolane to the pasty substance of step (3)...

Embodiment 2

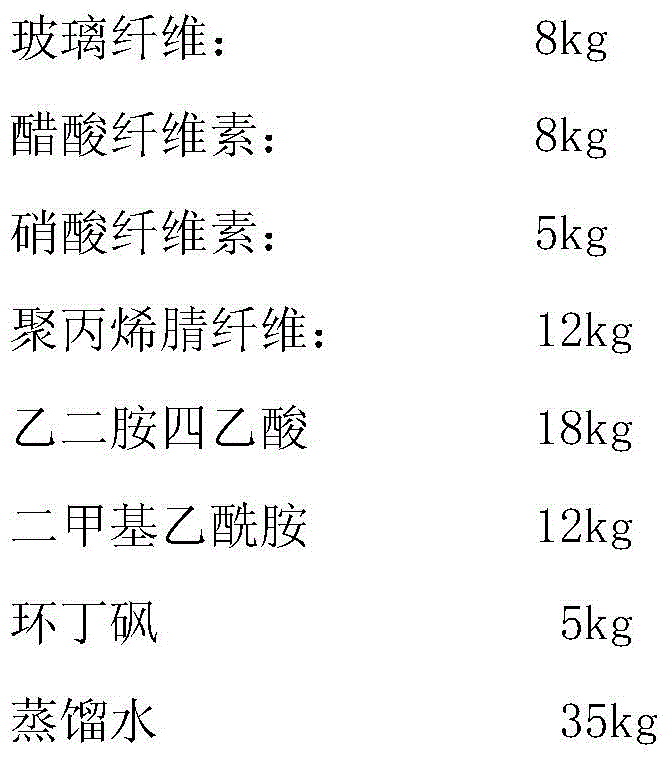

[0039] A biological filter paper prepared from the following components:

[0040]

[0041] The acetyl group content in the cellulose acetate is 40%-42%.

[0042] The acrylonitrile content in the polyacrylonitrile fiber is greater than 92%.

[0043] The quantification of the biological filter paper is 290g / m 2 , thickness 0.55mm, water absorption 1000g / m 2 .

[0044] Its preparation method comprises the following steps:

[0045] (1) Soak the glass fiber with 8% HCl at room temperature, and wash with water until there is no to no Cl atom;

[0046] (2) preparing a solution, stirring the ethylenediaminetetraacetic acid, dimethylacetamide and distilled water of the formula quantity to obtain a mixed solution;

[0047] (3) Glass fiber, cellulose acetate, nitrocellulose, and polyacrylonitrile fiber of formula quantity are dissolved in the mixed solution of step (2), fully stirred to obtain pasty substance;

[0048] (4) add sulfolane to the pasty substance of step (3), stir; ...

Embodiment 3

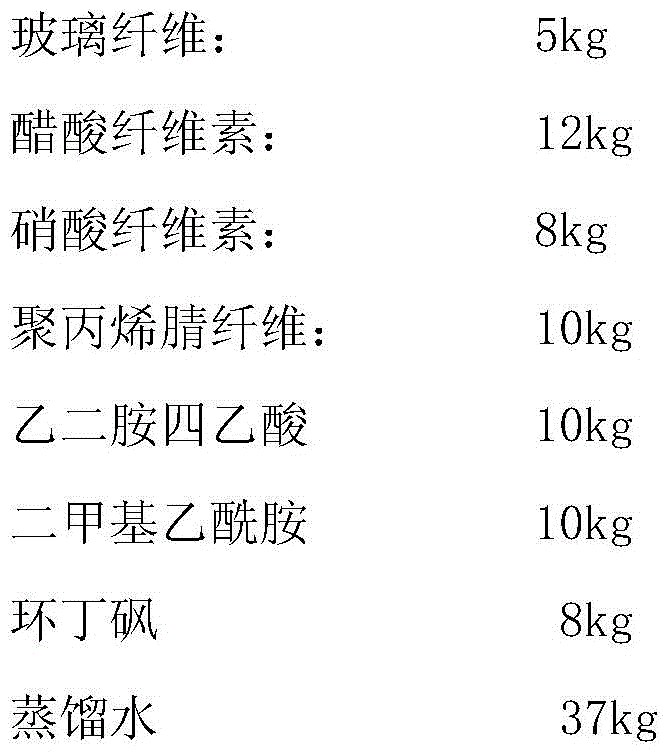

[0052] A biological filter paper prepared from the following components:

[0053]

[0054] The acetyl group content in the cellulose acetate is 40%-42%.

[0055] The acrylonitrile content in the polyacrylonitrile fiber is greater than 92%.

[0056] The quantification of described biological filter paper is 312g / m 2 , thickness 0.59mm, water absorption 890g / m 2 .

[0057] Its preparation method comprises the following steps:

[0058] (1) Soak the glass fiber with 8% HCl at room temperature, and wash with water until there is no to no Cl atom;

[0059] (2) preparing a solution, stirring the ethylenediaminetetraacetic acid, dimethylacetamide and distilled water of the formula quantity to obtain a mixed solution;

[0060] (3) Glass fiber, cellulose acetate, nitrocellulose, and polyacrylonitrile fiber of formula quantity are dissolved in the mixed solution of step (2), fully stirred to obtain pasty substance;

[0061] (4) add sulfolane to the pasty substance of step (3), s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com