Forward and reverse glove stacking, transporting and taking device and production process thereof

A technology of gloves and stacking, applied in the field of automatic equipment and its production process, to achieve the effect of reliable action, flexible and convenient operation, and soothing rotation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

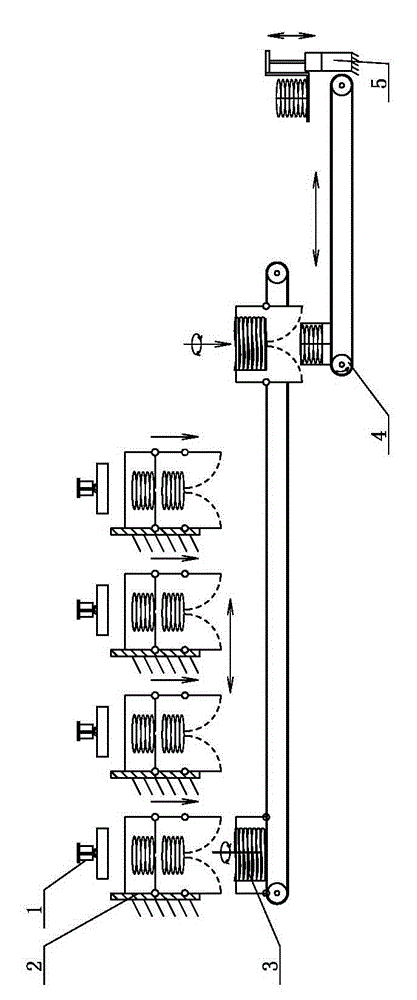

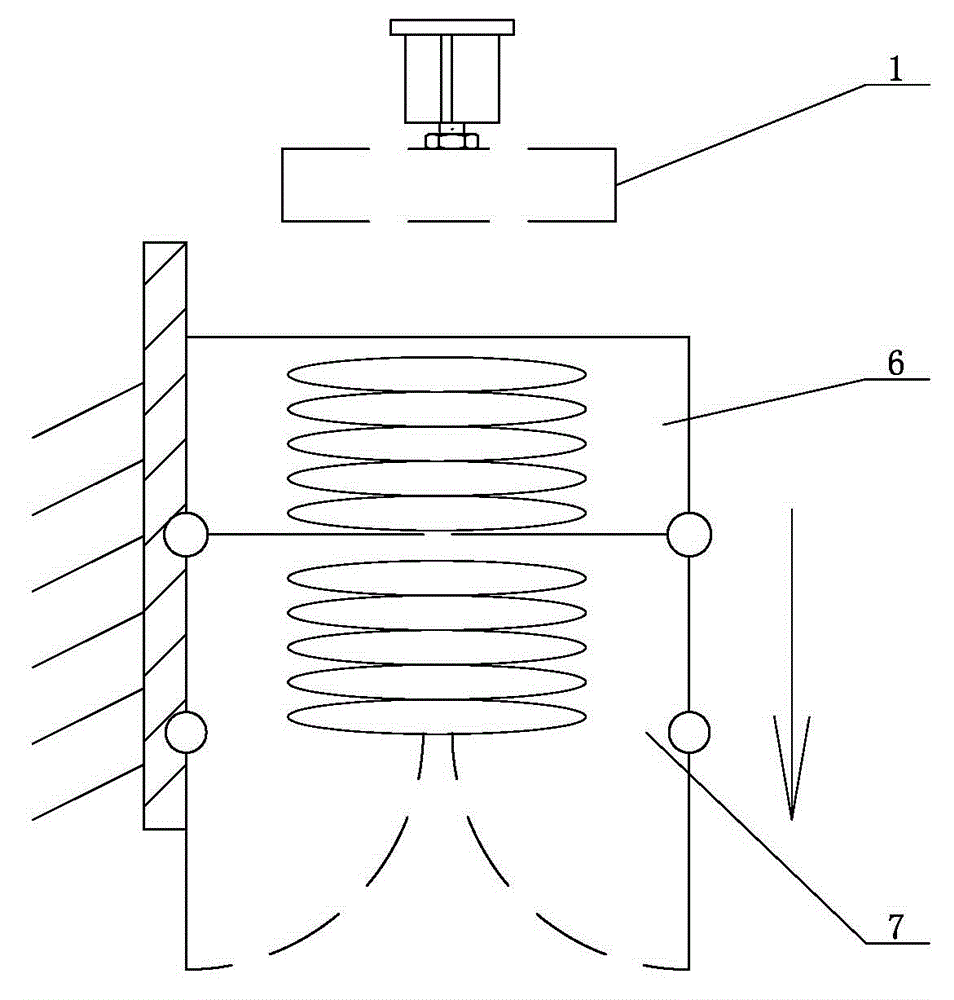

[0045] The device for conveying and retrieving the front and back stacks of gloves according to the present invention includes a system control device, a temporary glove storage part 2 , a rotating glove conveying part 3 and a glove transport and retrieving part 4 . The system controls include sensor counters. The system control device connects and controls the specific actions of the glove temporary storage part 2, the glove rotating and transporting part 3 and the glove transporting and fishing part 4 and the coordination between the mechanisms.

[0046] Such as figure 1 As shown, in this embodiment, the glove temporary storage part 2 includes four temporary storage groups, and the number setting of the temporary storage groups should be the same as the number of glove suction and release devices in the picking and stacking equipment, that is, in this embodiment If four suction cups 1 are provided, the number of temporary storage groups is correspondingly set to four groups...

Embodiment 2

[0063] In this embodiment, the opening and closing cylinder 22 used for opening and closing the bin door and the cylinder 18 that drives the fishing claw 17 to move up and down can also be replaced by linear motors. The opening and closing mechanism of the door can also adopt a sprocket chain and a gear meshing transmission mechanism, and all replacements known to those skilled in the art that can play equivalent effects are all allowed.

[0064] The first or second moving device can not only adopt the mode of conveyor belt or chain transmission, but also can adopt the structure of guide rail and pulley. That is, the first or second moving device includes a guide rail and a pulley, and the pulley is installed on the mounting frame; the pulley is connected to the mobile motor 15 through the transmission device, and the mobile motor 15 can drive the pulley to move forward and backward along the guide rail; Interference with guide rail.

[0065] The rotary power transmission gro...

Embodiment 3

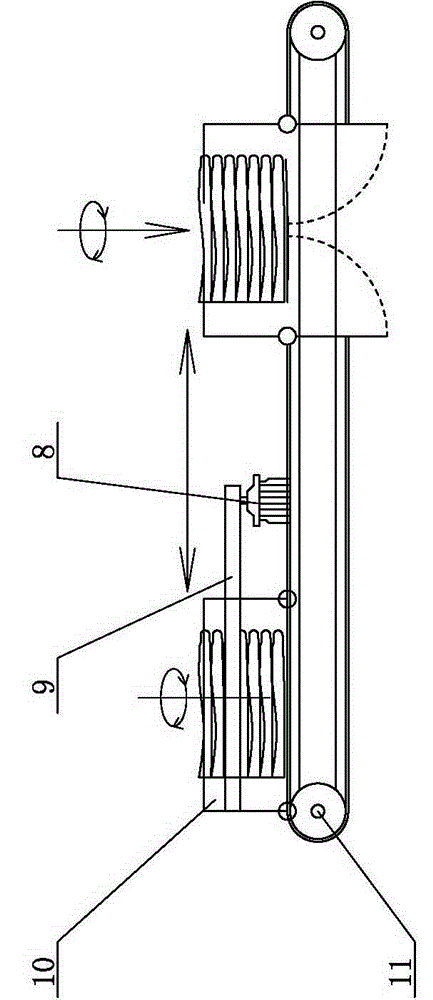

[0067] Such as Figure 11 As shown, in this embodiment, when the first mobile device and the second mobile device are arranged perpendicular to each other, N=(-1) n ×90, that is, N={90, -90, 90, -90...}. At this time, the step b of the production process of the glove front and back stack transportation fishing device can also adopt the following operation mode:

[0068]When the rotary box storehouse 10 was positioned below the first temporary storage group, the door of the transitional box storehouse 7 at the bottom of the temporary storage group was opened, and the gloves fell into the rotary box storehouse 10; Gloves are transported to the end of the first moving device 11, the system control device controls the rotating box 10 to rotate clockwise 90°, then the door of the rotating box 10 is opened, the gloves fall into the transfer box 16, and then the rotating box 10 continues Rotate 90° clockwise; the rotating box warehouse 10 moves below the second temporary storage gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com