Flavoring enhancing electronic cigarette sensory quality, and electronic cigarette liquid

A technology of electronic cigarettes and spices, which is applied in the direction of essential oils/flavors, tobacco, processed tobacco, etc. It can solve the problems of poor sensory quality and restrictions on the development of electronic cigarettes, and achieve the goals of easy implementation, improved smoking satisfaction, and reduced harm Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

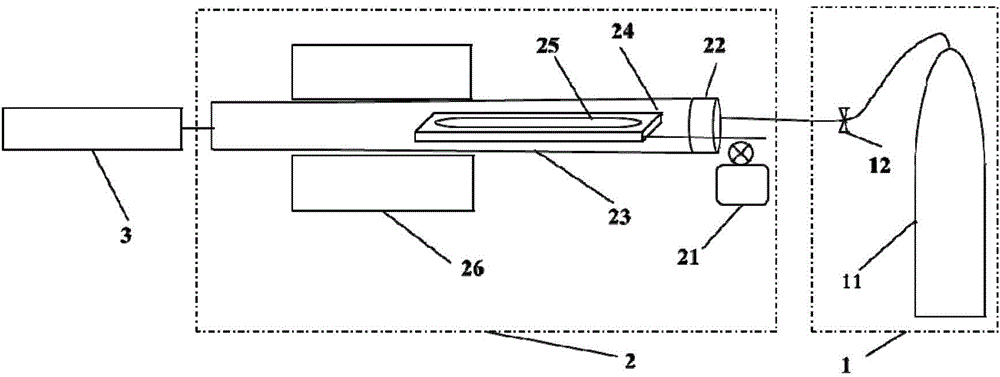

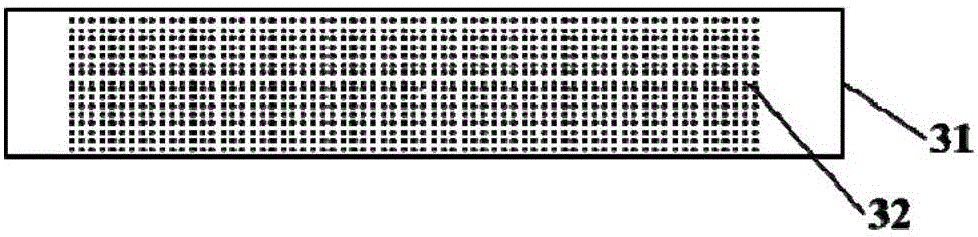

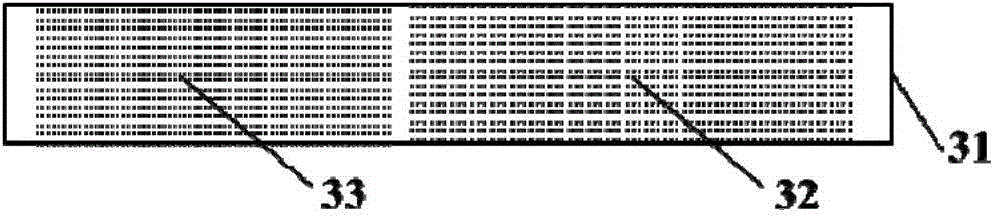

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Preparation of e-cigarette liquid

[0040] Under nitrogen protection, 500g Fujian Longyan flue-cured tobacco cut tobacco was pyrolyzed at 350°C, and the generated flue gas was introduced into the adsorption tube filled with mesoporous silica airgel as the adsorption material. After the flue gas was collected, the adsorbed The material is extracted in ethanol, and then filtered and concentrated to obtain the fragrance; the raw materials are: 20% of fragrance, 20% of glycerin, 2% of thickener, 5% of deionized water, and the balance is propylene glycol. Stir the raw materials evenly to obtain e-cigarette liquid, which is directly added to the e-cigarette device for atomization and smoking.

Embodiment 2

[0041] Example 2: Preparation of e-cigarette liquid

[0042] Under the protection of nitrogen, 1000g of Anhui flue-cured tobacco powder was pyrolyzed at 400 °C, and the generated flue gas was introduced into the adsorption tubes filled with mesoporous silica airgel and macroporous activated carbon as adsorption materials in sequence. After the capture is completed, the adsorption material is placed in ethanol for extraction, and then the fragrance is obtained by filtration and concentration. The raw materials are: 60% of fragrance, 10% of glycerin, 4% of thickener, 10% of deionized water, and the remaining The amount is propylene glycol, and all raw materials are mixed and stirred evenly to obtain e-cigarette liquid, which is directly added to the e-cigarette device for atomization and smoking.

Embodiment 3

[0043] Example 3: Preparation of e-cigarette liquid

[0044] Under the protection of nitrogen, 100 g of Xinjiang oriental tobacco leaves were pyrolyzed at 230 °C, and the generated flue gas was introduced into the adsorption tube filled with evenly mixed macroporous silica airgel and microporous activated carbon as adsorption materials, and the flue gas was captured. After the collection, the adsorption material is extracted in ethanol, and then concentrated by filtration to obtain the fragrance; the raw materials are: 35% of fragrance, 30% of glycerin, 2% of thickener, 8% of deionized water, and the remaining The amount is propylene glycol; mix all the raw materials and stir evenly to obtain the e-cigarette liquid, which is directly added to the electronic cigarette device for atomization and smoking.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com