Method for producing high-quality special steel through electric furnace all-molten-iron melting technique

An all-hot metal and electric furnace technology, applied in the field of steelmaking production, can solve the problems of unsatisfactory steel purity, strong oxidation of tapping slag and molten steel, unbearable production cost, etc., achieving the final composition level is simple and controllable, reducing molten steel Original oxidizing properties, reducing the possible effect of entering the ladle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] Example 1: Production of high carbon steel bearing steel GCr15

[0027] Adopt 100% full molten iron loading system, molten iron S≤0.050%, total loading capacity is 75 tons, and the furnace wall oxygen lance blows oxygen operation. The final carbon content is 0.56%, and the phosphorus content is 0.008%. Aluminum alloy is used for final deoxidation. The electric furnace uses Si-Mn alloy with Mn. The part that is insufficient for Si is filled with ferrosilicon, and high-carbon ferrochrome is used with chromium. The steel is tapped from the eccentric bottom, and 300kg of slagging material is added for tapping.

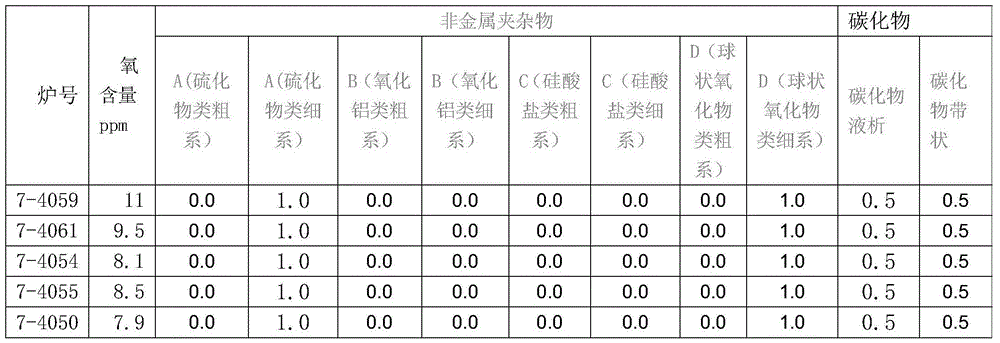

[0028] Table 1. Physical quality inspection results

[0029]

example 2

[0030] Example 2: Production of gear steel 20CrMnTi

[0031] Adopt 100% full molten iron loading system, molten iron S≤0.050%, total loading capacity is 75 tons, and the furnace wall oxygen lance blows oxygen operation. The carbon content at the end point is 0.08%, and the phosphorus content is 0.007%. Aluminum alloy is used for final deoxidation. The electric furnace uses Si-Mn alloy with Mn. The eccentric bottom is tapped, and 200kg of slagging material is added for tapping.

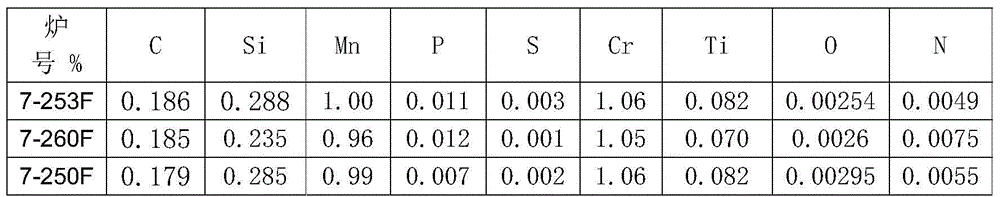

[0032] Table 2 Chemical composition of 20CrMnTi object

[0033]

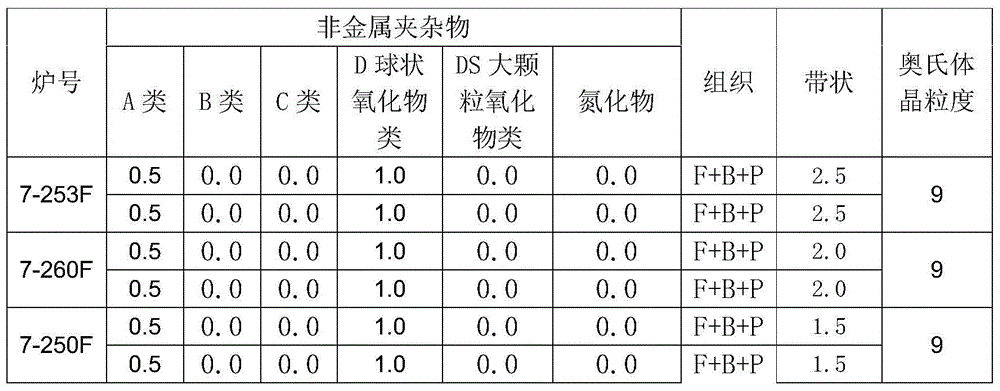

[0034] Table 3 Metallographic results of 20CrMnTi objects

[0035]

[0036] technical effect

[0037] (1) By using the electric furnace full iron molten iron smelting process, the amount of molten iron charged can reach 100%, and the carbon content at the end point can be controlled, which reduces power consumption and the consumption of raw and auxiliary materials such as scrap steel and carbon powder, and saves production cost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com