A kind of ultrafine nanoporous metal and preparation method thereof

A porous metal and ultra-fine nanotechnology, applied in the field of ultra-fine nano-porous metal and its preparation, to achieve the effect of mild reaction, round structure and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

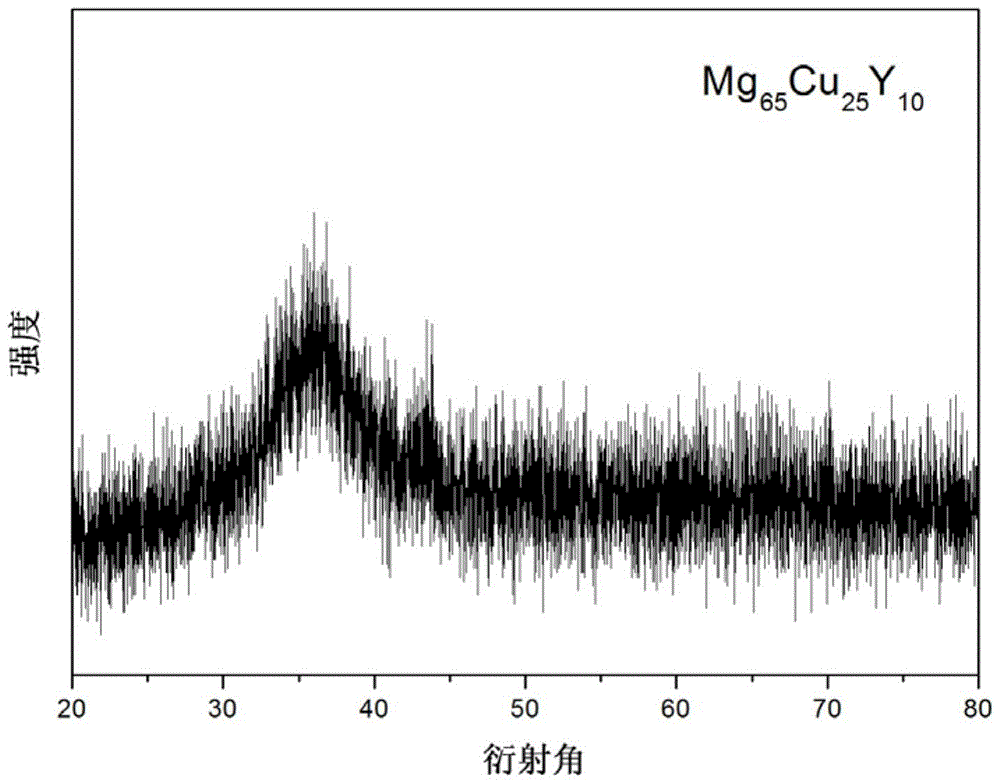

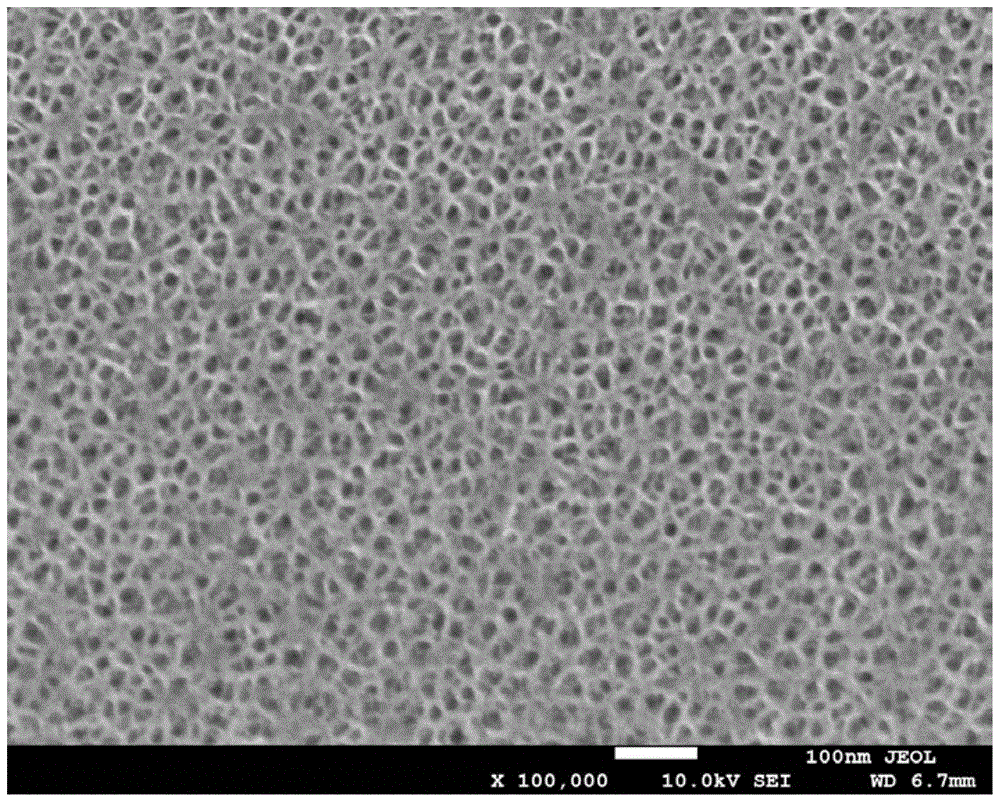

[0053] Example 1: Using Mg 65 Cu 25 Y 10 Preparation of nanoporous copper using amorphous alloy as precursor

[0054] In this embodiment, the selected amorphous alloy precursor composition is Mg 65 Cu 25 Y 10 The preparation method of nanoporous materials is as follows:

[0055] Step 1: Ingredients

[0056] Press Mg 65 Cu 25 Y 10 The nominal composition weighs each elemental element and becomes the raw material for preparing the master alloy ingot.

[0057] Step 2: Melting the pre-alloy

[0058] Press Cu and Y elements as Mg 65 Cu 25 Y 10 The nominal composition is smelted in a vacuum arc smelting furnace for 3-4 times to obtain CuY ingots;

[0059] The melting conditions are: the vacuum degree in the vacuum arc melting furnace during melting is 8×10 -3 Below Pa, fill with 0.5Mpa high-purity argon, smelt for 1-2 minutes each time, and smelt 3-4 times.

[0060] Step 3: Melting the master alloy

[0061] According to Mg 65 Cu 25 Y 10 Nominal composition, take a slight excess of Mg and mix wit...

Embodiment 2

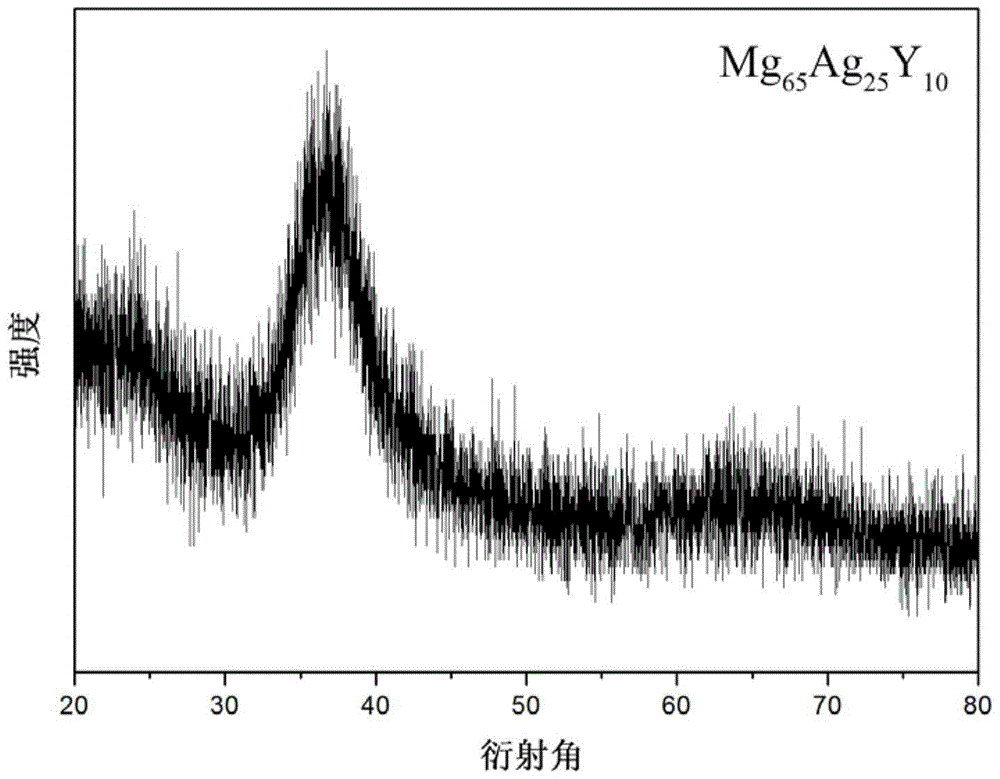

[0072] Example 2: Using Mg 65 Ag 25 Y 10 Preparation of nanoporous silver from bulk amorphous alloy as precursor

[0073] In this embodiment, the selected amorphous alloy precursor composition is Mg 65 Ag 25 Y 10 The preparation method of nanoporous materials is as follows:

[0074] Step 1: Ingredients

[0075] Press Mg 65 Ag 25 Y 10 The nominal composition weighs each elemental element and becomes the raw material for preparing the master alloy ingot.

[0076] Step 2: Melting the pre-alloy

[0077] Press Ag and Y elements as Mg 65 Ag 25 Y 10 The nominal composition is smelted in a vacuum arc smelting furnace, refining 3-4 times to obtain AgY ingots;

[0078] The melting conditions are: the vacuum degree in the vacuum arc melting furnace during melting is 8×10 -3 Below Pa, fill with 0.5Mpa high-purity argon, smelt for 1-2 minutes each time, and smelt 3-4 times.

[0079] Step 3: Melting the master alloy

[0080] According to Mg 65 Ag 25 Y 10 Nominal composition, take a slight excess of Mg a...

Embodiment 3

[0091] Example 3: Using Mg 65 Cu 20 Y 15 Preparation of nanoporous copper using amorphous alloy as precursor

[0092] In this embodiment, the selected amorphous alloy precursor composition is Mg 65 Cu 20 Y 15 The preparation method of nanoporous materials is as follows:

[0093] Step 1: Ingredients

[0094] Press Mg 65 Cu 20 Y 15 The nominal composition weighs each elemental element and becomes the raw material for preparing the master alloy ingot.

[0095] Step 2: Melting the pre-alloy

[0096] Press Cu and Y elements as Mg 65 Cu 20 Y 15 The nominal composition is smelted in a vacuum arc smelting furnace for 3-4 times to obtain CuY ingots;

[0097] The melting conditions are: the vacuum degree in the vacuum arc melting furnace during melting is 8×10 -3 Below Pa, fill with 0.5Mpa high-purity argon, smelt for 1-2 minutes each time, and smelt 3-4 times.

[0098] Step 3: Melting the master alloy

[0099] According to Mg 65 Cu 20 Y 15 Nominal composition, take a slight excess of Mg and mix wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com