Centrifugal air shower drying machine

An air shower dryer and centrifugal technology, applied in the field of centrifugal air shower dryer, can solve the problems of long processing cycle, watermark pollution, low qualification rate, etc., and achieve compact installation controls, avoid interference, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

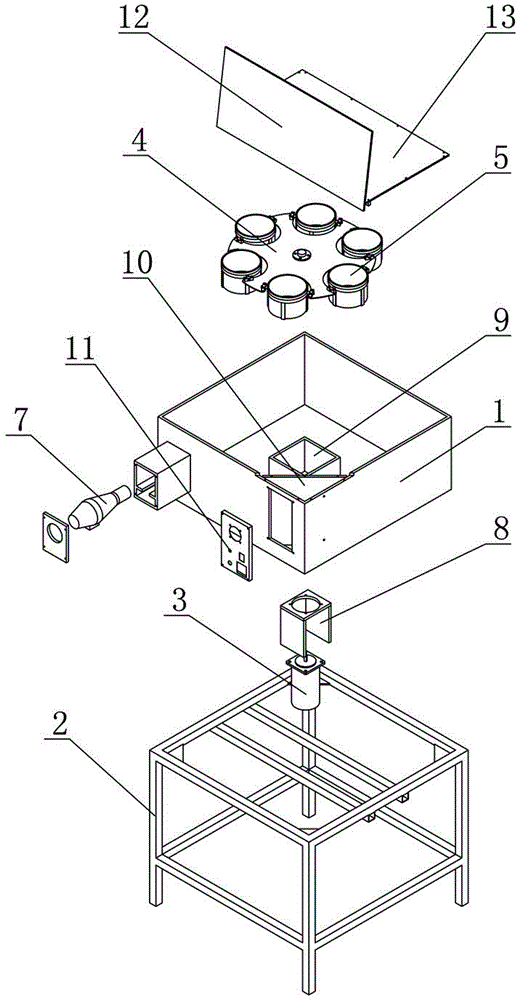

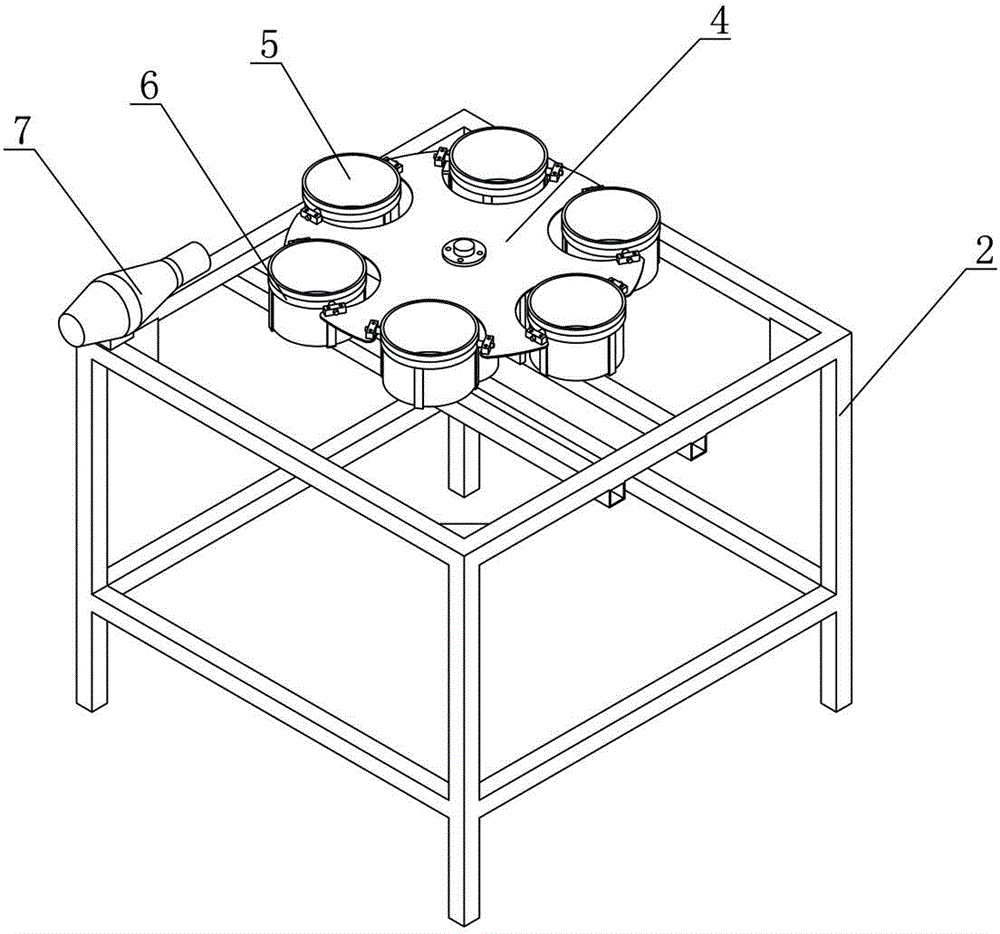

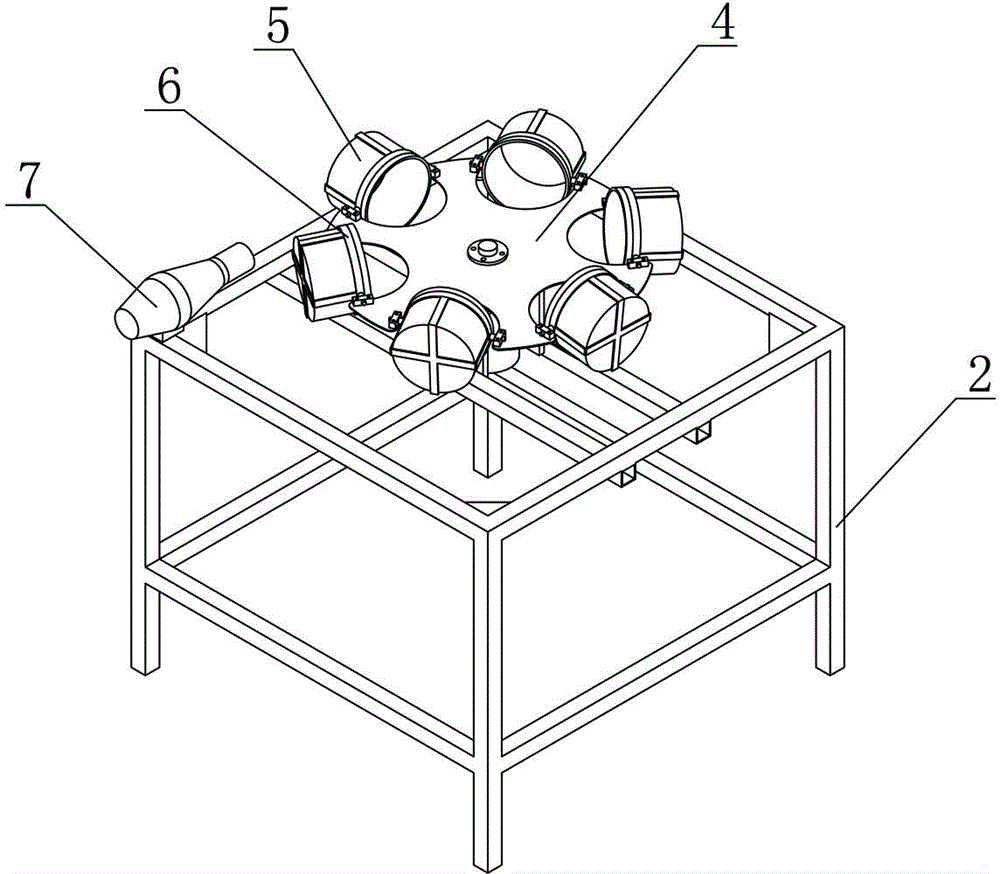

[0037] Such as Figure 1-Figure 4 As shown, a centrifugal air shower dryer includes a PVC box body, a transparent PVC box cover, a stainless steel frame located in the PVC box body, a speed-regulating motor installed on the stainless steel frame, and the speed-regulating motor Driven centrifugal device and the control panel of the hot air blower and speed regulating motor arranged at the side of the stainless steel box, the air outlet of the hot air blower is set corresponding to the lower part of the flywheel disc. This set of equipment saves the step of alcohol dehydration, which reduces the cost. In addition, after this step is omitted, the temperature difference between the front and the back is reduced, the crystal plate is not easy to crack, and the yield rate is high.

[0038] The centrifugal device includes a flywheel disc driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com