Heat exchanger and semi-conductor wine cabinet

A heat exchanger and semiconductor technology, applied in indirect heat exchangers, lighting and heating equipment, household refrigeration devices, etc., can solve the problems of low noise, zero noise, zero vibration, etc. Experience, evenly distributed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

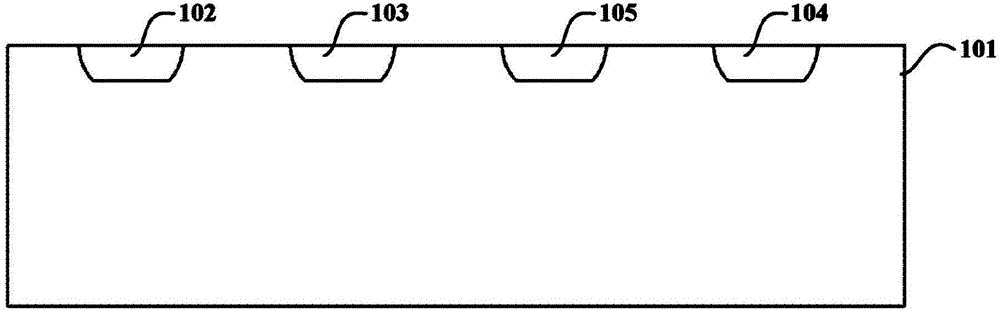

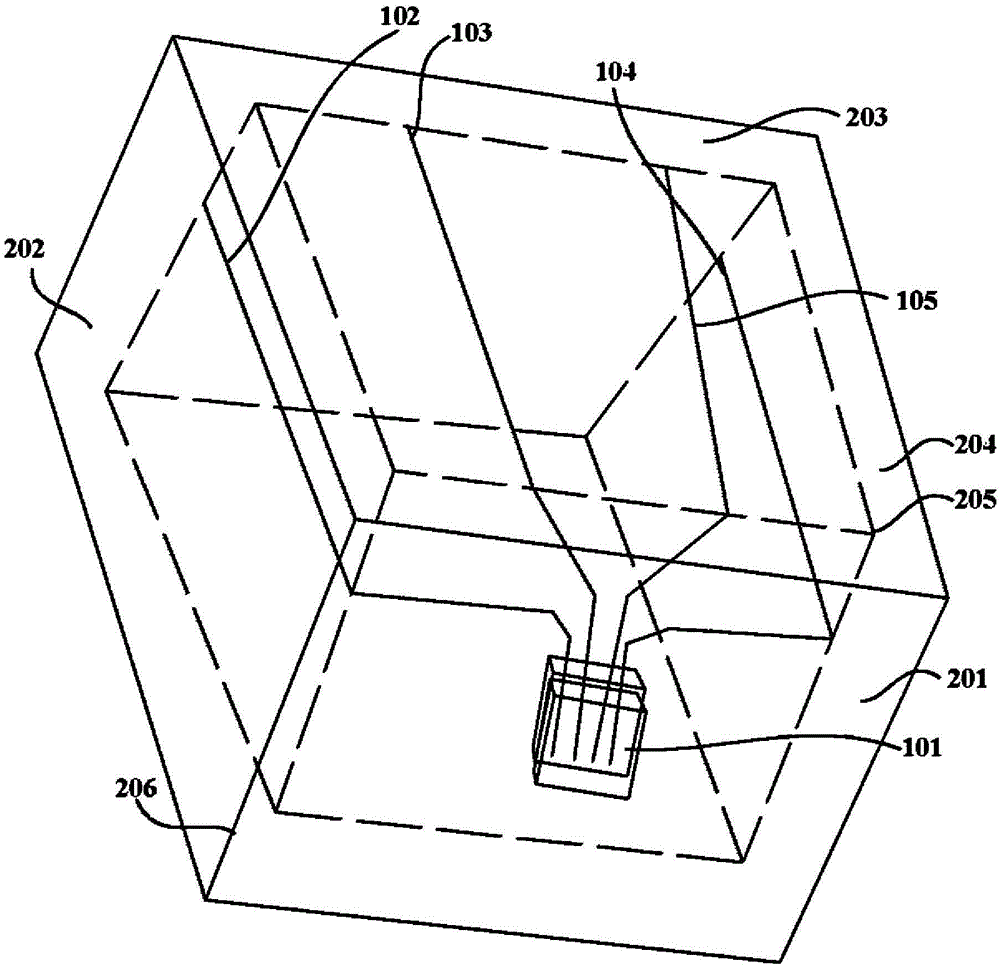

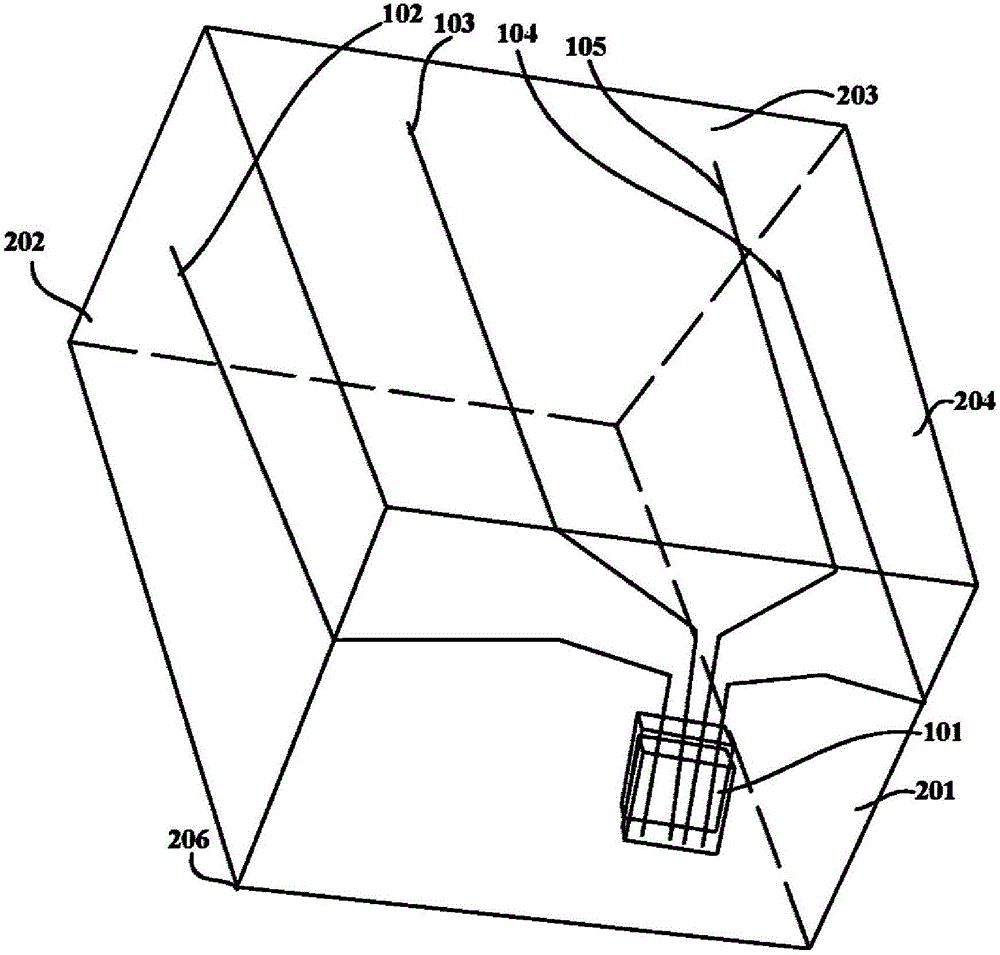

[0043] figure 1 It is a cross-sectional view along the radial direction of the heat pipe of the heat exchange block of the heat exchanger and the heat pipe embedded therein according to an embodiment of the present invention. Depend on figure 1 It can be seen that the heat exchanger may include a heat exchange block 101 and a plurality of mutually independent heat pipes. Both ends of each heat pipe are sealed and refrigerant is sealed inside the heat pipe. exist figure 1 In the shown embodiment, the first end of each heat pipe can be embedded into the heat exchange block 101 by pressing and embedding to improve the firmness of the connection between the two; and at least the part of the heat pipe embedded in the heat exchange block 101 is flat tube. Since the heat exchange efficiency of the flat tube is higher than that of the circular tube, the heat exchange efficiency between the heat pipe and the heat exchange block 101 is also improved.

[0044]In an embodiment of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com