Heat exchanger and semi-conductor wine cabinet

A heat exchanger and semiconductor technology, applied in indirect heat exchangers, lighting and heating equipment, household refrigeration devices, etc., can solve the problems of low noise, zero noise, zero vibration, etc. Experience and improve the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

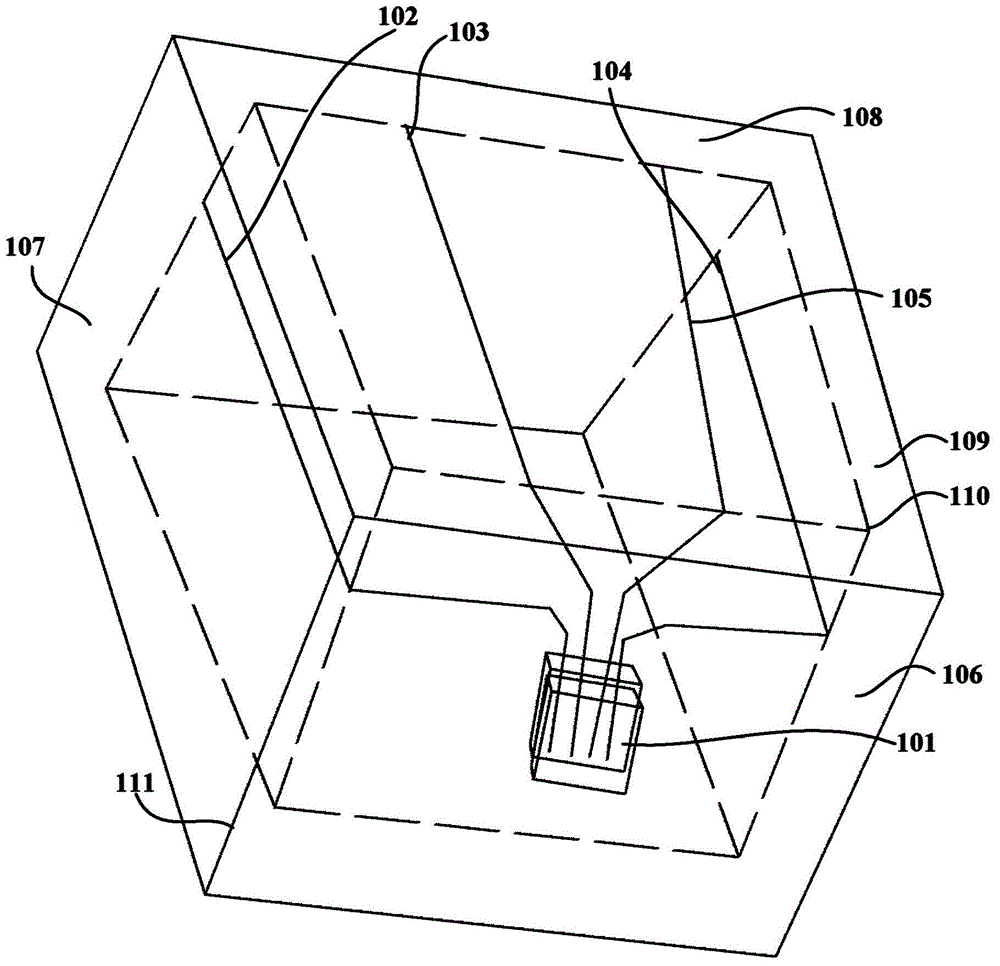

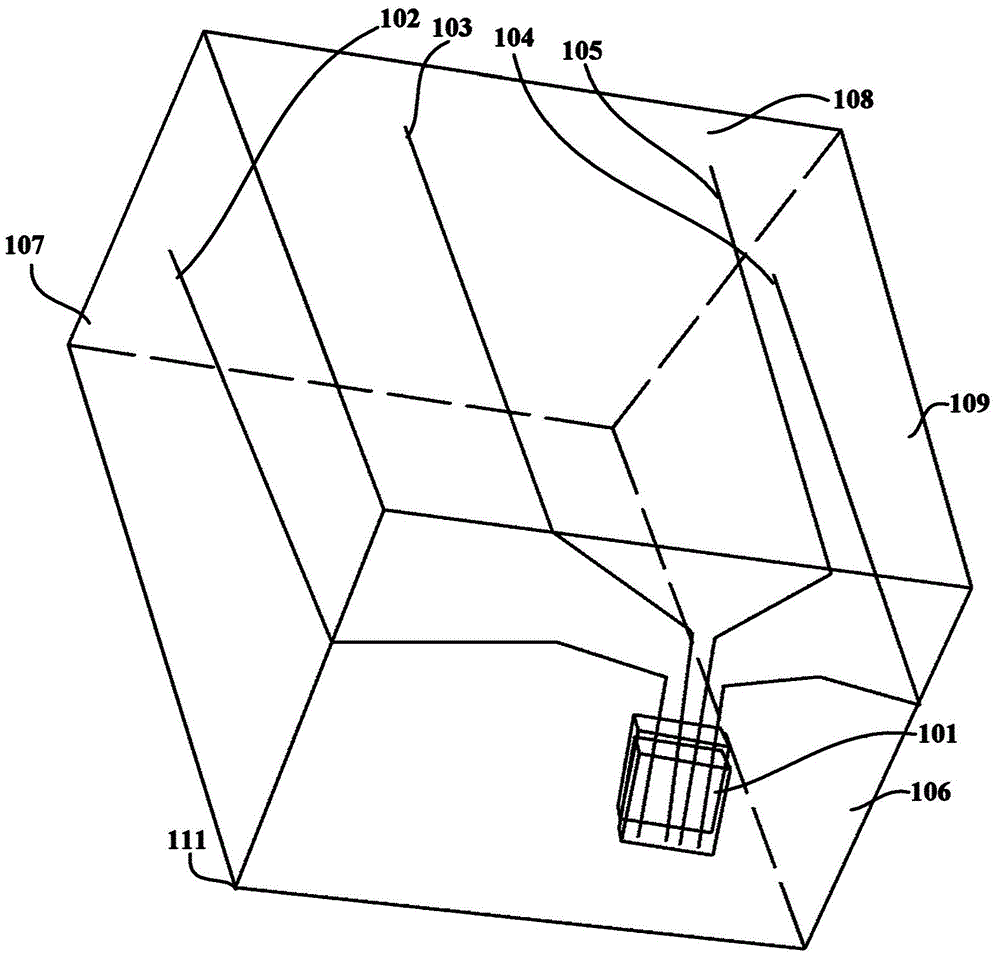

[0044] figure 1 It is a structural schematic diagram of a semi-conductor wine cabinet using a heat exchanger to exchange heat for the cold end of a semi-conductor refrigeration sheet according to an embodiment of the present invention.

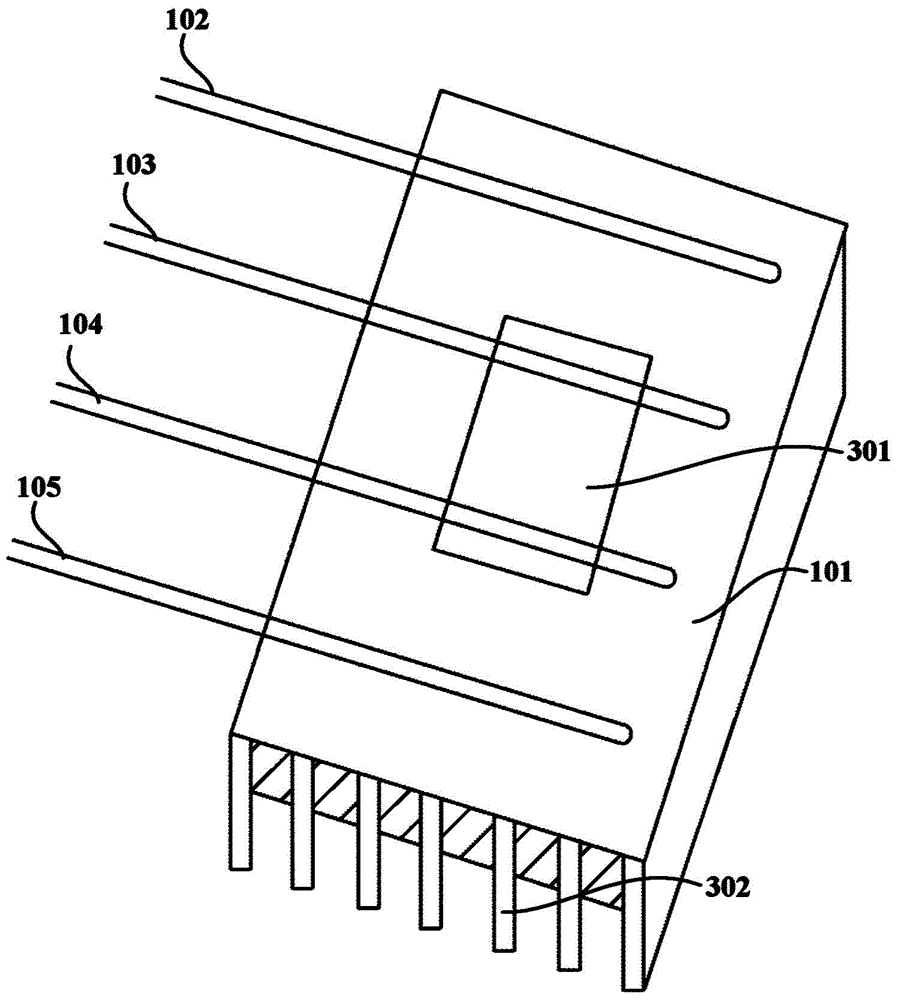

[0045] exist figure 1 In the illustrated embodiment, the heat exchanger may include a heat exchange block 101 and a plurality of independent heat pipes. Both ends of each heat pipe are closed and refrigerant is sealed inside the heat pipe, and the first end of each heat pipe is in thermal contact with the heat exchange block 101 .

[0046] Depend on figure 1It can be seen that, in the embodiment of the present invention, the plurality of mutually independent heat pipes may at least include the first heat pipe 102 to the third heat pipe 104 . Wherein, after the first heat pipe 102 protrudes from the heat exchange block 101, it extends to the first plane 106, extends along a straight line in the first plane 106, and bends to the second plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com