An ultrasonic atomization sampling device

A sampling device, ultrasonic atomization technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as residues, achieve the effects of improving accuracy, reducing interference, and preventing non-directionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

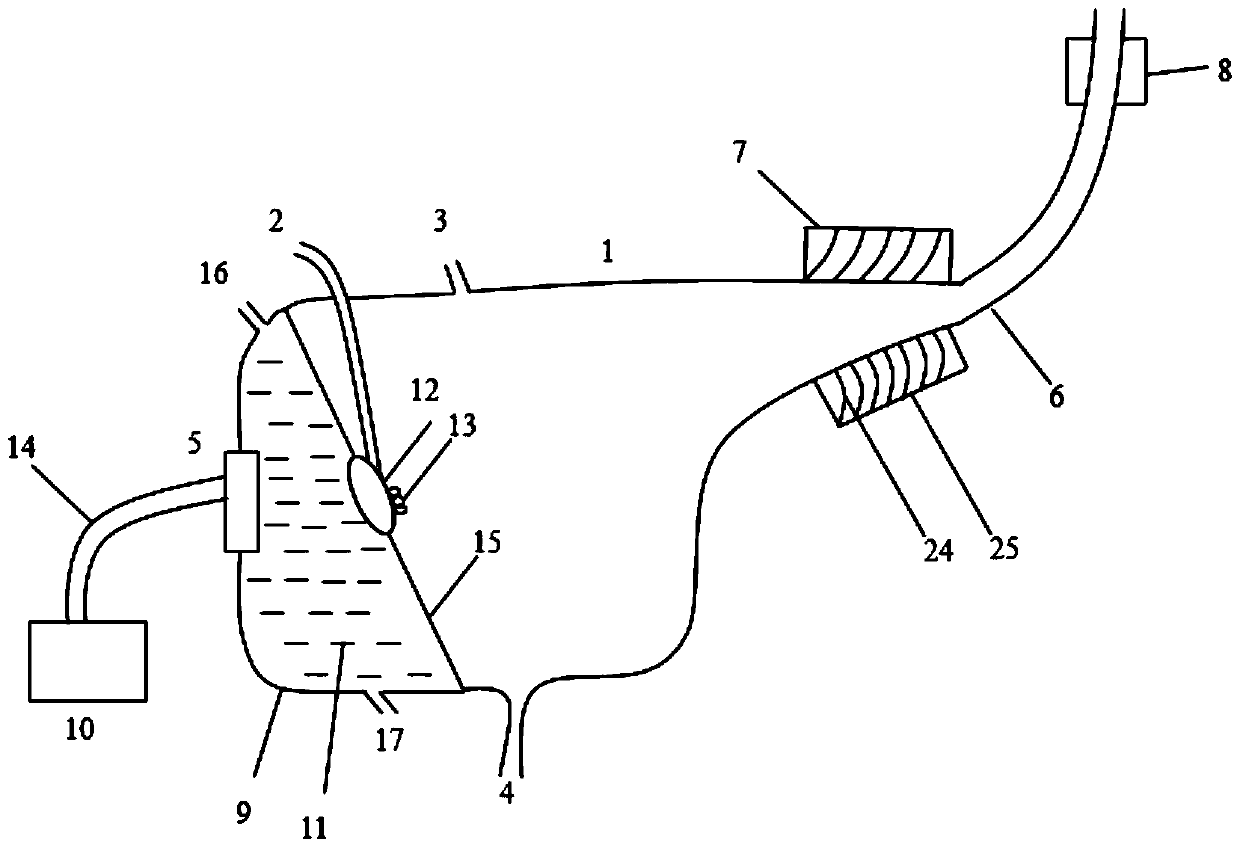

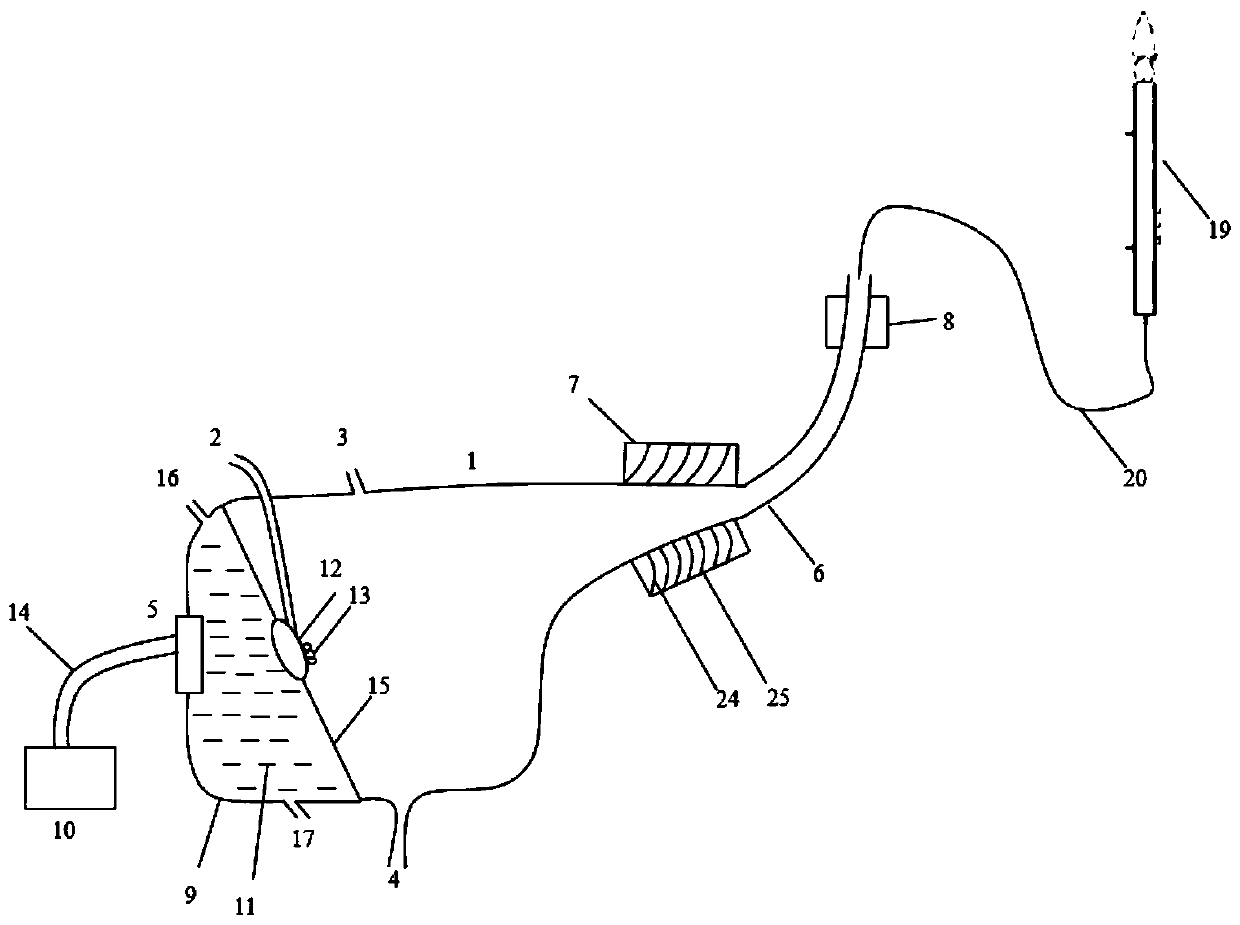

[0040] Such as figure 1 As shown, an ultrasonic atomization sampling device, the isolation glass 15 installed obliquely divides the cavity into a coupling chamber 9 and a spray chamber 1, and a resonant membrane 12 is installed in the center of the isolation glass 15 with an inclination of 60°.

[0041] An ultrasonic transducer 5 is installed on the side wall of the coupling chamber 9 , and the ultrasonic transducer 5 is electrically connected to the ultrasonic generating circuit 10 through a cable 14 . The interior of the coupling chamber 9 is filled with coupling water 11 , the upper part of the coupling chamber 9 communicates with the water inlet pipe 16 , and the lower part communicates with the water outlet pipe 17 .

[0042] The atomization chamber 1 has a fan-shaped structure of 30°. The upper part of the atomization chamber 1 extends into the sampling tube 2 , and the outlet of the sampling tube 2 is close to the resonant membrane 12 for transporting the sample solutio...

Embodiment 2

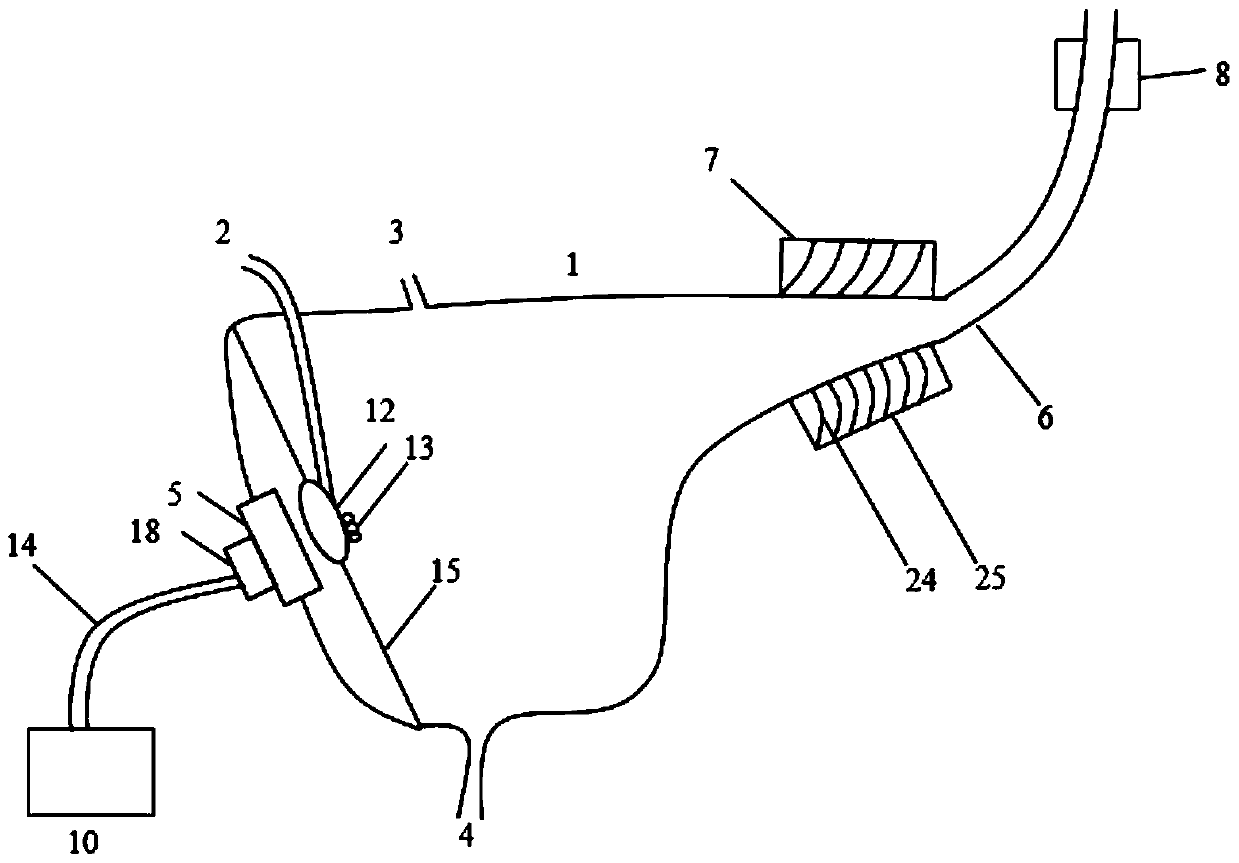

[0051] Such as image 3 As shown, an ultrasonic atomization sampling device differs from Embodiment 1 in that instead of using coupling water 11 and a circulating cooling system, the resonant membrane 12 is directly pasted on the surface of the ultrasonic transducer 5 to simplify coupling. The resonant film 12 is parallel to the ultrasonic transducer 5, and the inclination is set to 45° in this embodiment according to the required conditions. The resonant membrane 12 is close to the ultrasonic transducer 5 to ensure that the ultrasonic energy is directly coupled to the resonant membrane 12 through the air.

[0052] A cooling device 18 is installed on the surface of the ultrasonic transducer 5 for cooling the ultrasonic transducer 5 .

[0053] Such as Figure 4 As shown, the cooling device 18 includes a cooling fin 21 and a cooling plate 23, the cooling plate 23 is bonded to the ultrasonic transducer 5, and the cooling fin 21 is evenly inserted on the surface of the cooling p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com