Method for determining chemical components in tobacco dry distillated flavor

A technology of chemical composition and determination method, which is applied in the field of tobacco analysis, can solve problems such as large errors, and achieve the effect of accurate and reliable determination results and simple and fast determination methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

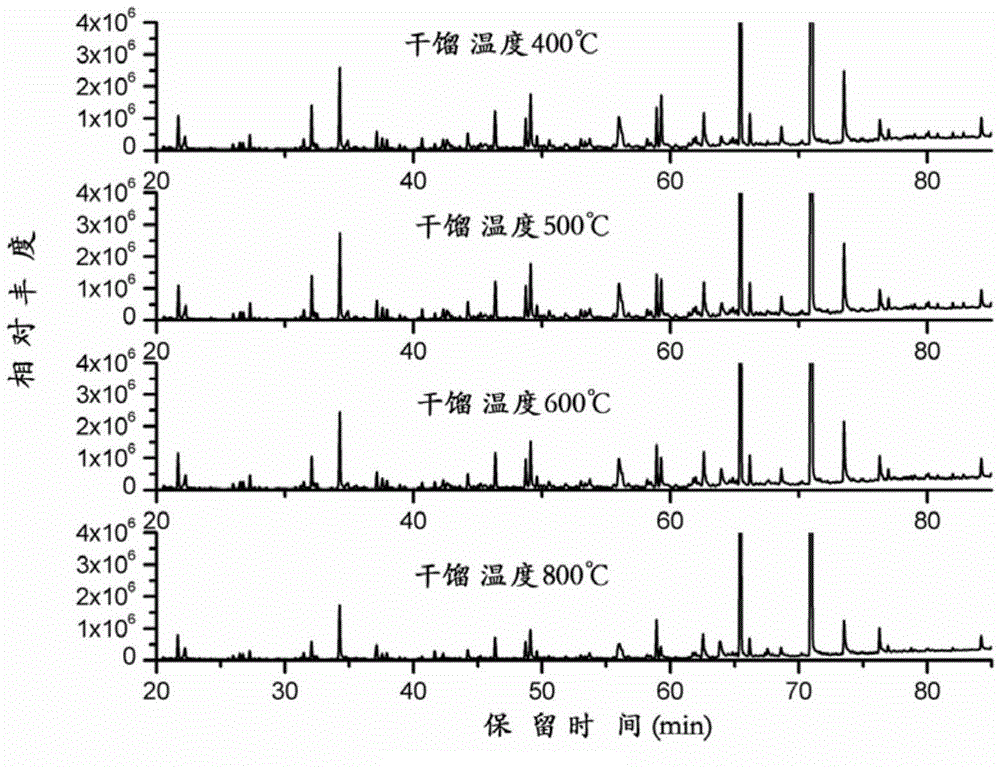

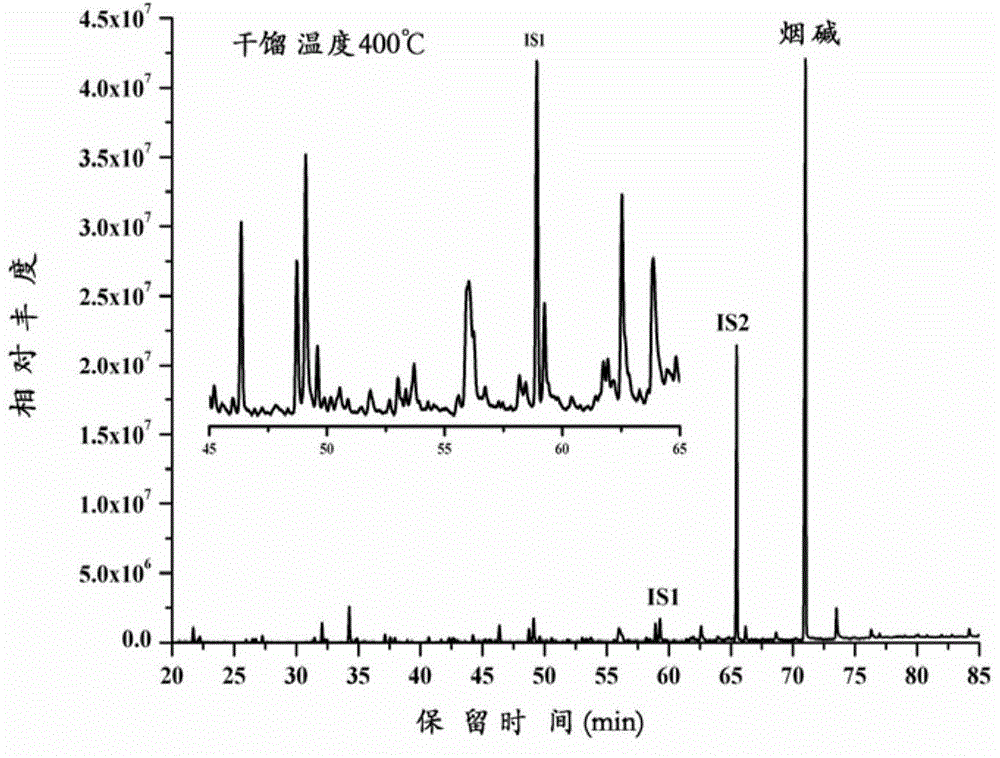

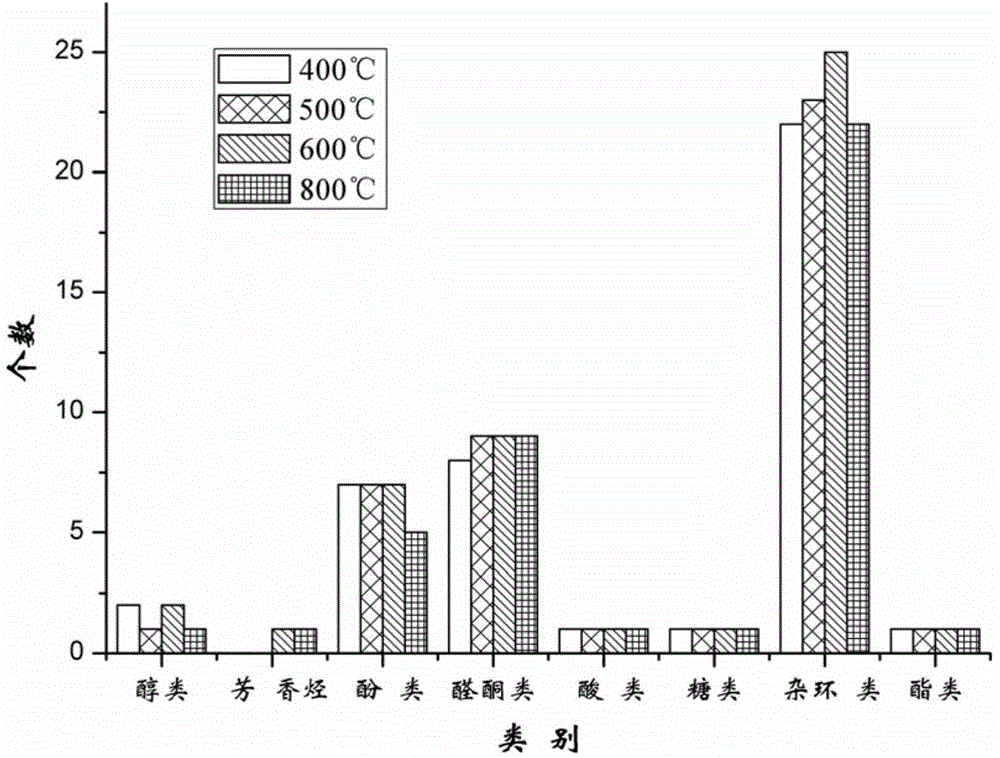

[0044] Weigh 4g of shredded tobacco and put it into a tube furnace, heat it to 400°C, and keep the temperature constant for 2.5h. The flue gas produced by dry distillation is brought into the absorption bottle placed in the cold trap with nitrogen gas. The absorption bottle is pre-installed with 25mL of propylene glycol. The temperature of the cold trap is -15°C, the smoke condensate in the pipeline is washed out with 40mL propylene glycol, the absorption liquid in the absorption bottle is combined with the smoke condensate washed out in the pipeline, and the tobacco dry distillation flavor is obtained.

Embodiment 2

[0046] Weigh 4g of shredded tobacco and put it into a tube furnace, heat it to 500°C, and keep the temperature constant for 2.5h. Use nitrogen to bring the flue gas generated by dry distillation into an absorption bottle placed in a cold trap. The absorption bottle is pre-installed with 25mL of propylene glycol. The temperature of the cold trap is -15°C, the smoke condensate in the pipeline is washed out with 40mL propylene glycol, the absorption liquid in the absorption bottle is combined with the smoke condensate washed out in the pipeline, and the tobacco dry distillation flavor is obtained.

Embodiment 3

[0048] Weigh 4g of shredded tobacco and put it into a tube furnace, heat it to 600°C, and keep the temperature constant for 2.5h. Use nitrogen to bring the flue gas produced by dry distillation into an absorption bottle placed in a cold trap. The absorption bottle is pre-installed with 25mL of propylene glycol. The temperature of the cold trap is -15°C, the smoke condensate in the pipeline is washed out with 40mL propylene glycol, the absorption liquid in the absorption bottle is combined with the smoke condensate washed out in the pipeline, and the tobacco dry distillation flavor is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionization energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com