Temperature control system for liquor fermentation pit

A temperature control system and cellar technology, applied in the field of wine making, can solve problems such as the unsatisfactory temperature control effect, achieve the effects of reducing movement resistance, increasing contact area, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

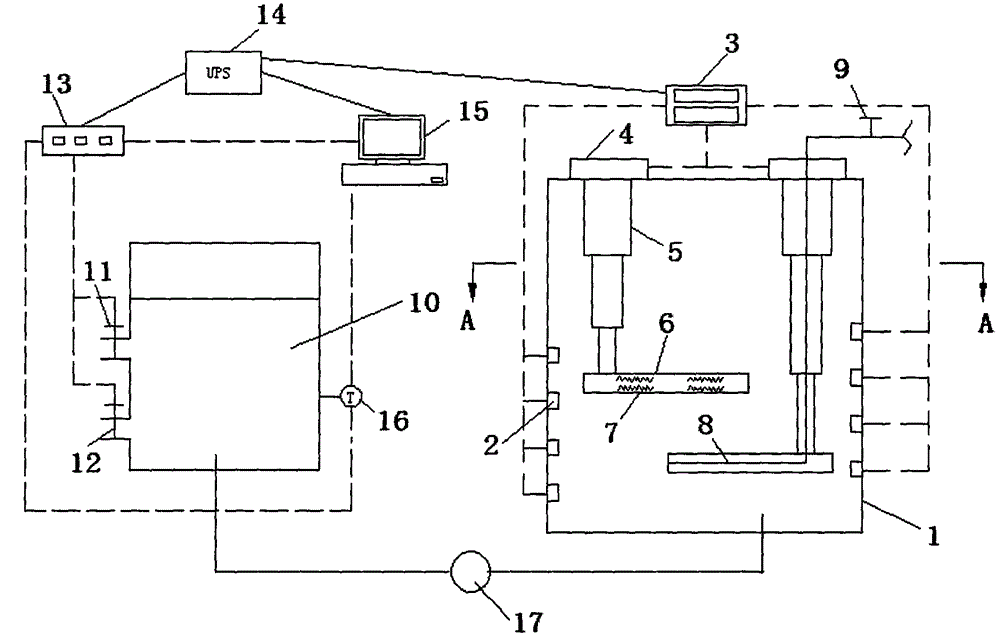

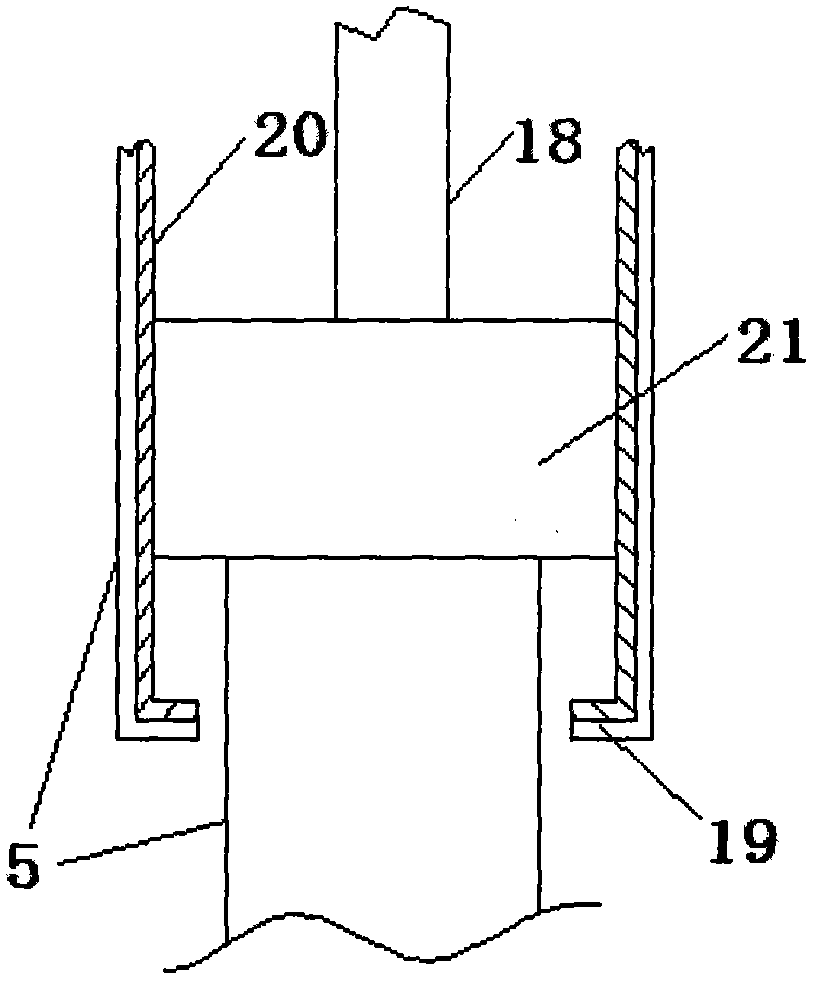

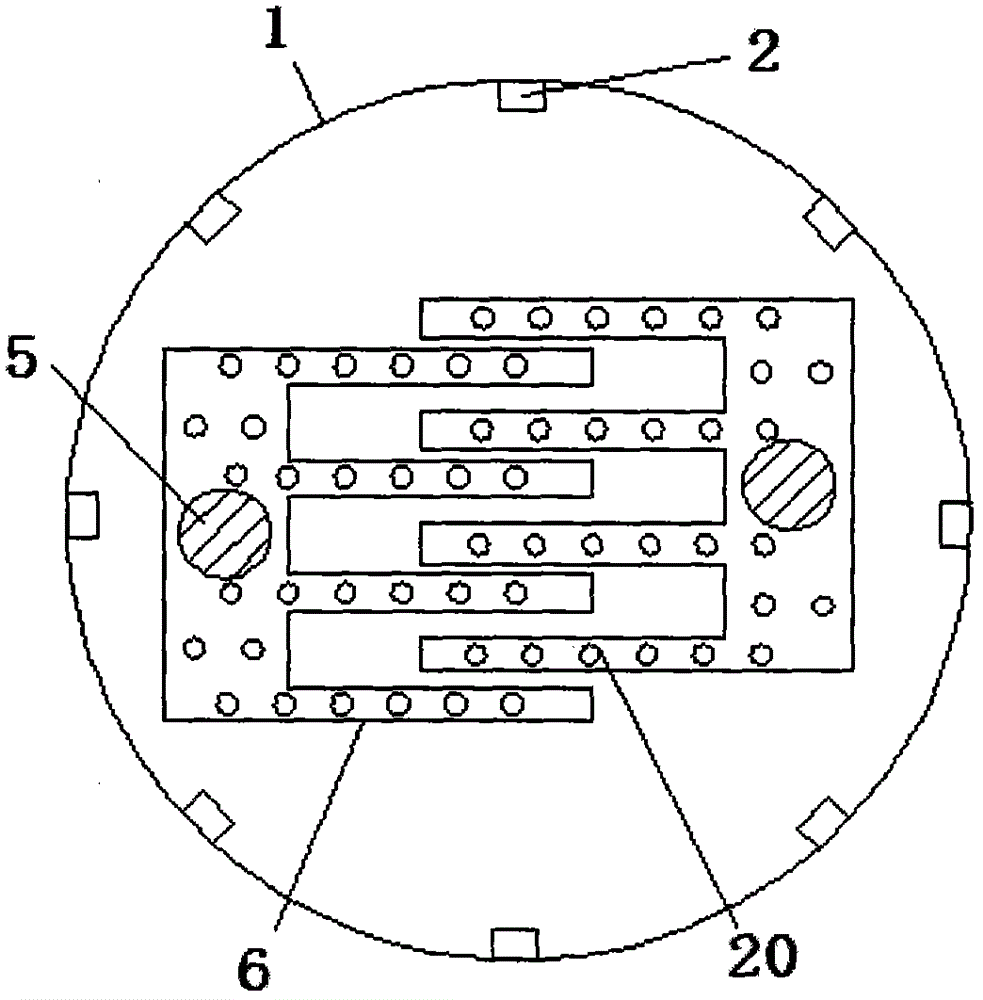

[0020] Such as Figure 1-3 As shown, the embodiment of the present invention provides a liquor cellar temperature control system, which includes a cellar 1, a water supply tank 10 and a controller 3, and is characterized in that several The first temperature sensor 2, the top of the cellar 1 is provided with two servo motors 4, the servo motor 4 is engaged with a transmission link 18, the transmission link 18 extends into the cellar 1, and the outside of the transmission link 18 is provided with There are several sections of telescopic sleeves 5 that are nested in each other. The ends of the last stage of telescopic sleeves 5 are respectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com