Radio frequency sensor and impedance matching device

A technology of radio frequency sensor and radio frequency transmission, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, electrical components, etc. Matching range and matching effect, improving service life, and increasing the effect of process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order for those skilled in the art to better understand the technical solution of the present invention, the radio frequency sensor and the impedance matching device provided by the present invention will be described in detail below with reference to the accompanying drawings.

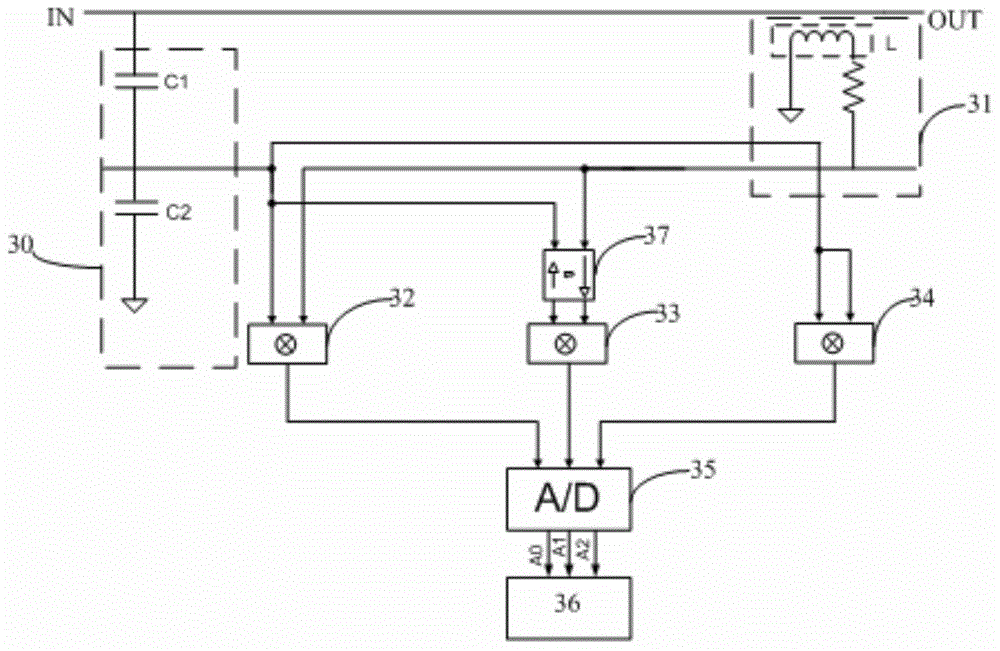

[0029] image 3 A schematic structural diagram of a radio frequency sensor provided by an embodiment of the present invention. see image 3 The radio frequency sensor provided in this embodiment is used to detect the presence of low frequency radio frequency power according to the voltage and current signals on the radio frequency transmission line, and the radio frequency sensor includes a voltage acquisition module 30, a current acquisition module 31, a first analog multiplier 32, a second An analog multiplier 33 , a third analog multiplier 34 , an analog-to-digital conversion module 35 , a control module 36 and a phase shift module 37 . Among them, such as image 3 As shown, the voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com