Plasma waste gas treatment device

A waste gas treatment device and plasma technology, which are applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of difficult removal of high-concentration polluted waste gas and the lack of substantial breakthrough in waste gas treatment level. Improve the treatment level, increase the distance, save energy and efficiently remove the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

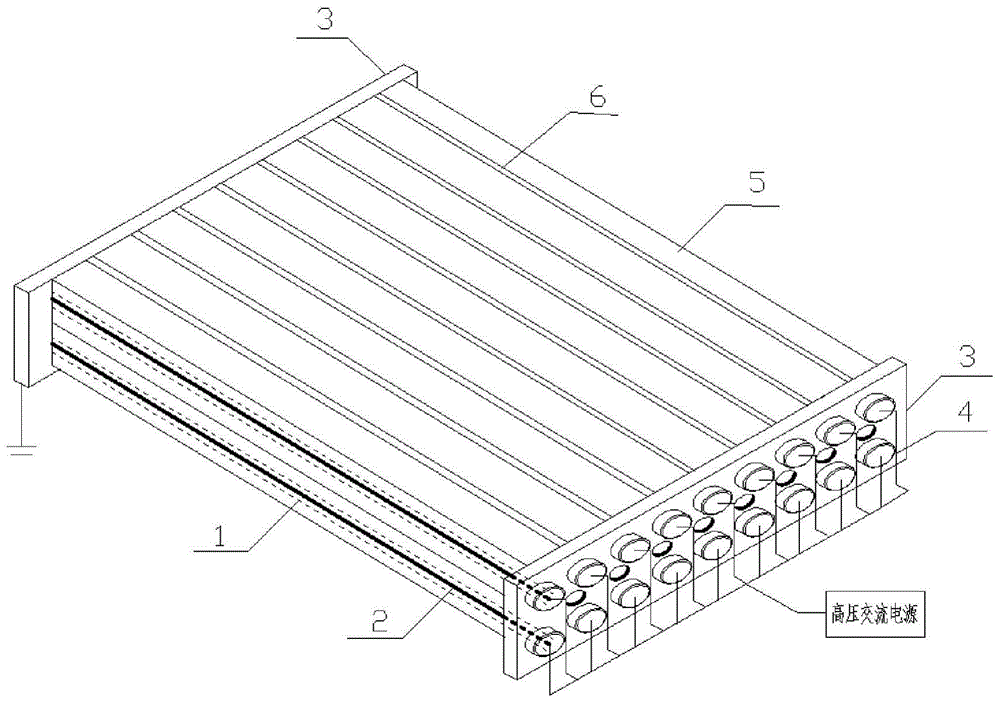

[0025] Such as figure 1 The plasma exhaust gas treatment device shown includes a base frame and several discharge units. According to the treatment efficiency and the treatment gas volume, the discharge units can be disassembled and / or assembled to have a structure of at least one level and one row. The technical solution of the present invention is described below by taking multi-level and multi-row as an example (of course, the technical solutions of single, single-row and single-row structural forms are also covered by the present invention.); wherein:

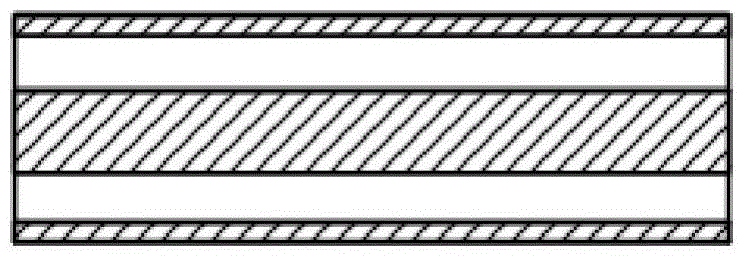

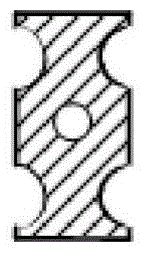

[0026] Each discharge unit includes a metal electrode 2 and an insulating dielectric layer 1 that coaxially wraps it. The material of the dielectric layer 1 can be quartz or polytetrafluoroethylene; the number of rows of electrodes 2 can be adjusted according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com