Sporopollen microcapsule, and preparation method and application thereof

A technology of microcapsules and sporopollen, which is applied in the field of sporopollen microcapsules and its preparation, which can solve problems such as production and property hazards, easy decomposition and deterioration, unevenness, etc., to achieve efficient industrial production, improve removal efficiency, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

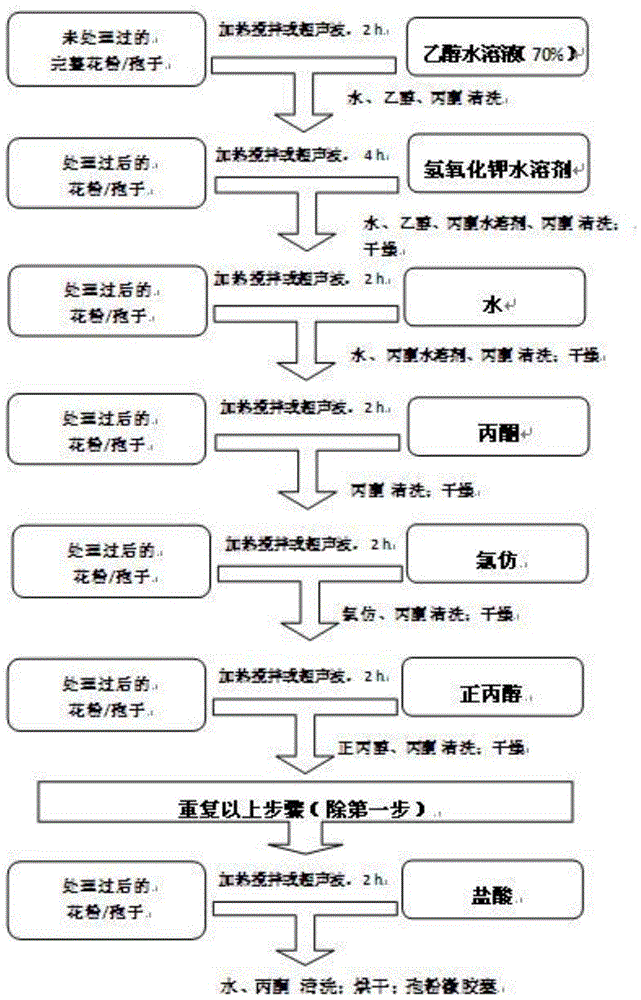

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of the sporopollen microcapsules described in the present embodiment specifically comprises the steps:

[0044] Add 1 g of untreated complete forget-me-not pollen to 25 mL of 40% ethanol solution and soak for 2 hours, remove the solution, wash the treated pollen with 25 mL of deionized water, and finally heat and dry in air to obtain .

[0045] This embodiment also provides a sporopollen microcapsule preparation, which includes the sporopollen microcapsules prepared by the above method and a capsule core embedded in the sporopollen microcapsules. The capsule core can be cosmetics, food, medicine, paint, dye, essence or other active ingredients.

Embodiment 2

[0047] The preparation method of the sporopollen microcapsules described in the present embodiment specifically comprises the steps:

[0048] Add 1g of untreated intact Ganoderma lucidum spores to 25mL to a concentration of 95gL -1 Potassium hydroxide solution, heated to 100 ° C and stirred for 4 hours, the solvent was removed to leave spores, and then the spores were washed three times with 25 mL of 40% acetone solution, and finally heated and dried in the air to obtain .

[0049] This embodiment also provides a sporopollen microcapsule preparation, which includes the sporopollen microcapsules prepared by the above method and a capsule core embedded in the sporopollen microcapsules. The capsule core can be cosmetics, food, medicine, paint, dye, essence or other active ingredients.

Embodiment 3

[0051] The preparation method of the sporopollen microcapsules described in the present embodiment specifically comprises the steps:

[0052] Add 1 g of untreated intact Agrocybe spores to 25 mL of water and soak, heat to 25°C and stir for 2 hours, remove the water, then wash the spores twice with 15 mL of acetone, and finally heat to 50°C in air and bake Dry for 1 hour, that is.

[0053] This embodiment also provides a sporopollen microcapsule preparation, which includes the sporopollen microcapsules prepared by the above method and a capsule core embedded in the sporopollen microcapsules. The capsule core can be cosmetics, food, medicine, paint, dye, essence or other active ingredients.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size range | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com