Preparation method of grafted high-capacity dendrimer ion chromatography stationary phase packing

A dendrimer and ion chromatography technology, which is applied to the application field of the preparation of grafted high-capacity ion chromatography packing, can solve the problems of difficult separation, insurmountable, low separation degree of monosaccharides and disaccharides, etc., and achieves the synthesis cycle. Short, high capacity, high separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention discloses a preparation method of a high-capacity dendrimer graft type ion chromatography stationary phase, comprising: preparation of dendrimers, polystyrene-divinylbenzene-glycidyl methacrylate (PS- The preparation of DVB-GMA) microspheres, the grafting of dendrimers on the surface of microspheres, the quaternization modification of dendrimers and the preparation of quaternized dendrimer grafted chromatographic stationary phase fillers, the present invention The specific technical scheme is as follows:

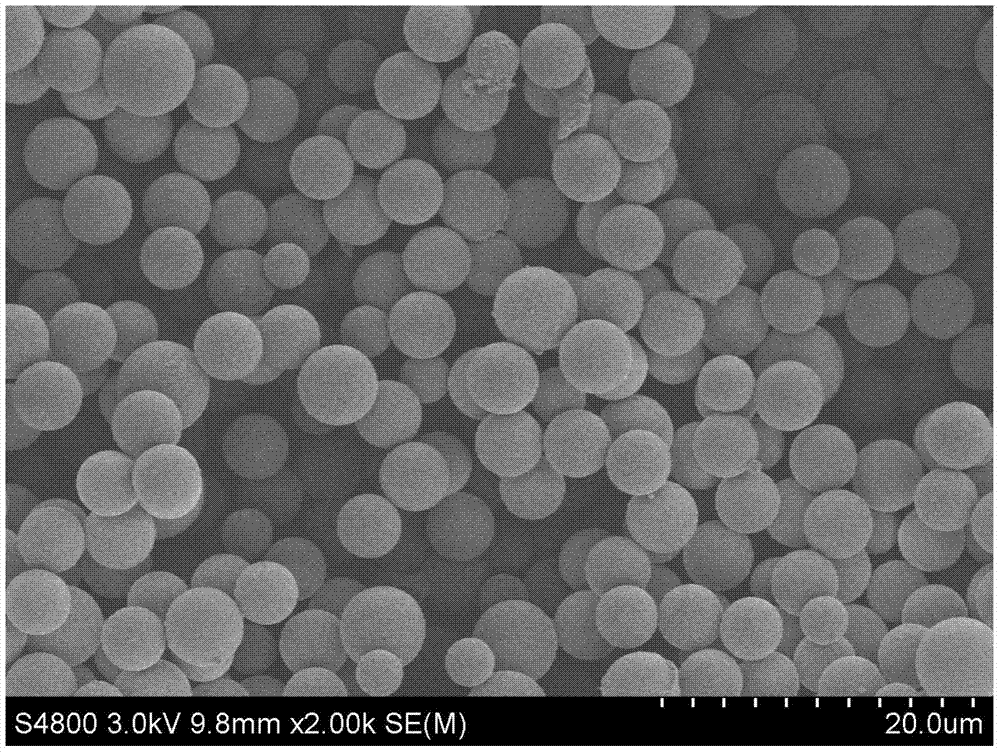

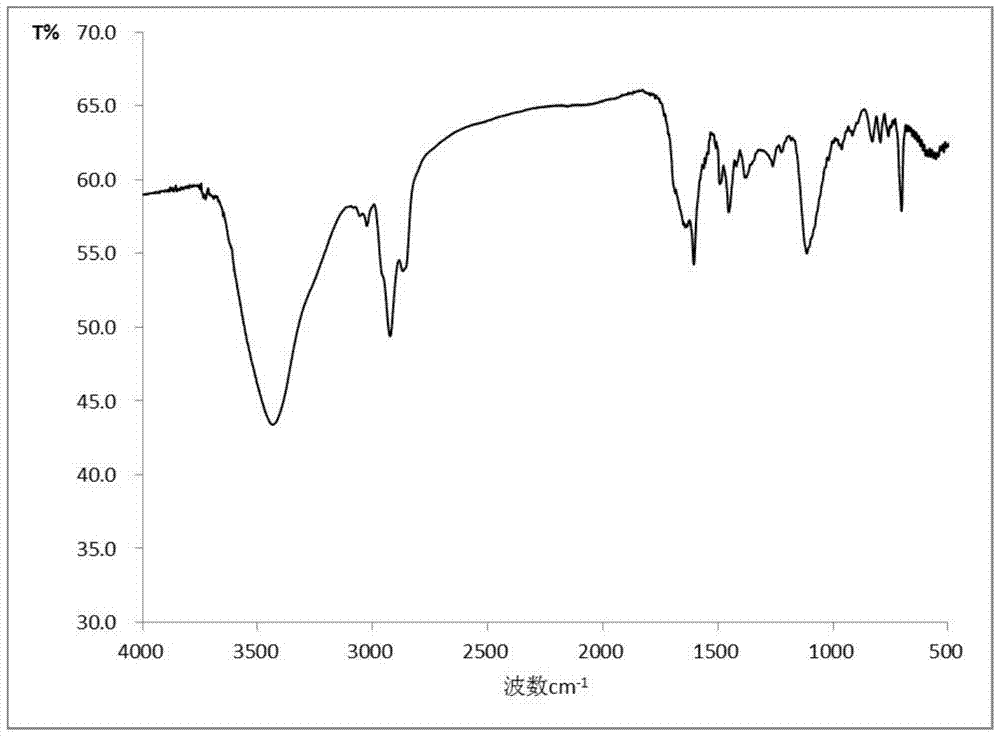

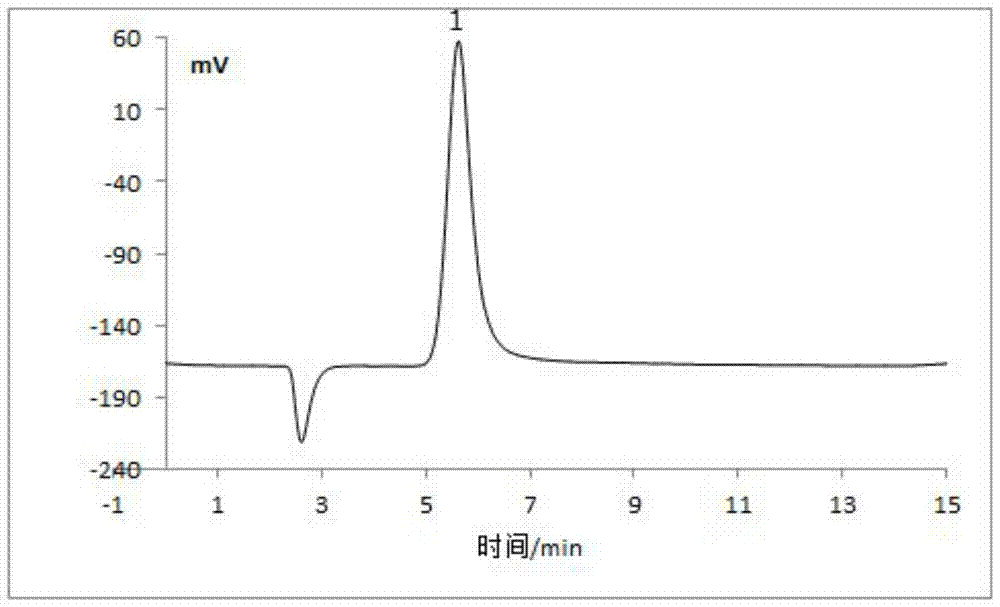

[0028] Using styrene-divinylbenzene-glycidyl methacrylate (PS-DVB-GMA) as the matrix, monodisperse linear polystyrene microsphere seeds were prepared by dispersion polymerization, and the activated The seeds synthesized polystyrene-divinylbenzene-glycidyl methacrylate (PS-DVB-GMA) microspheres with a large number of epoxy groups on the surface, and extracted to remove the porogen. Then the synthesized polyamide-amine dendrimers were grafted onto the sur...

Embodiment 1

[0036] Embodiment 1: The preparation process of grafted high-capacity dendrimer ion chromatography stationary phase packing is as follows, and its steps are:

[0037] 1. Preparation of PAMAM: Dissolve 2mL of ethylenediamine in 25mL of methanol, slowly add 25g of methyl acrylate under stirring in an ice-water bath, slowly raise the temperature to 28°C after the dropwise addition, and stir React for 24 hours to obtain 0.5G of PAMAM; dissolve 5g of 0.5GPAMAM in 25mL of methanol, and slowly add 15g of ethylenediamine dropwise under stirring in an ice-water bath. Macromolecules (1.0 GPAMAM).

[0038] 2, the preparation of polystyrene seed, synthetic particle diameter 1~3 μm monodisperse polystyrene seed by emulsion dispersion polymerization method, the concentration of monomeric styrene is 15% (m / m) of total amount, stabilizer polyvinylpyrrolidone Consumption is 2% (m / v) of reaction medium, and initiator azobisisobutyronitrile consumption is 1% (m / m) of monomer consumption, and re...

Embodiment 2

[0043] Embodiment 2: with reference to the method and steps of embodiment 1

[0044] 1. Preparation of PAMAM: Dissolve 2mL of ethylenediamine in 25mL of methanol, slowly add 25g of methyl acrylate under stirring in an ice-water bath, slowly raise the temperature to 28°C after the dropwise addition, and stir React for 24 hours to obtain 0.5G of PAMAM; dissolve 5g of 0.5GPAMAM in 25mL of methanol, and slowly add 15g of ethylenediamine dropwise under stirring in an ice-water bath. Macromolecules (1.0 GPAMAM).

[0045] 2, the preparation of polystyrene seed, synthetic particle diameter 1~3 μm monodisperse polystyrene seed by emulsion dispersion polymerization method, the concentration of monomeric styrene is 15% (m / m) of total amount, stabilizer polyvinylpyrrolidone Consumption is 2% (m / v) of reaction medium, and initiator azobisisobutyronitrile consumption is 1% (m / m) of monomer consumption, and reaction medium is dehydrated alcohol, and 60 ℃ of reaction temperatures, stirring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com